2Mirka® AIROS • 77 mm (3"), 125 mm (5") & 150 mm (6") • Tool manual Mirka® AIROS • 77 mm (3"), 125 mm (5") & 150 mm (6") • Tool manual 3

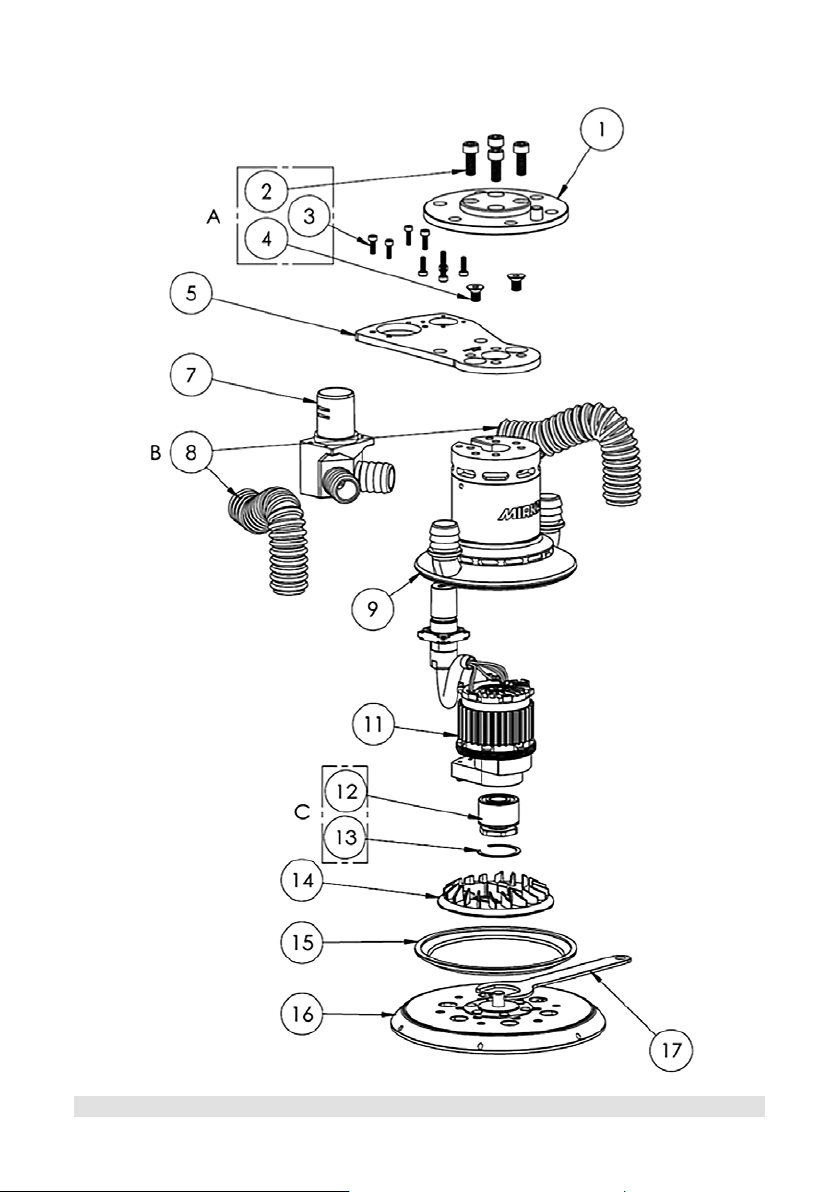

Installation overview

Installation steps

1. Remove dust protector cap from the connector.

2. Mount the tool on a matching counter-flange. If the force sensor

or the robot used has a flange of a different size an adapter may be

required. If the counter-flange is larger by a significant amount there

may be a need for an increase in tool offset on the adapter to prevent

unnecessary wear, or obstruction of the hose and cable.

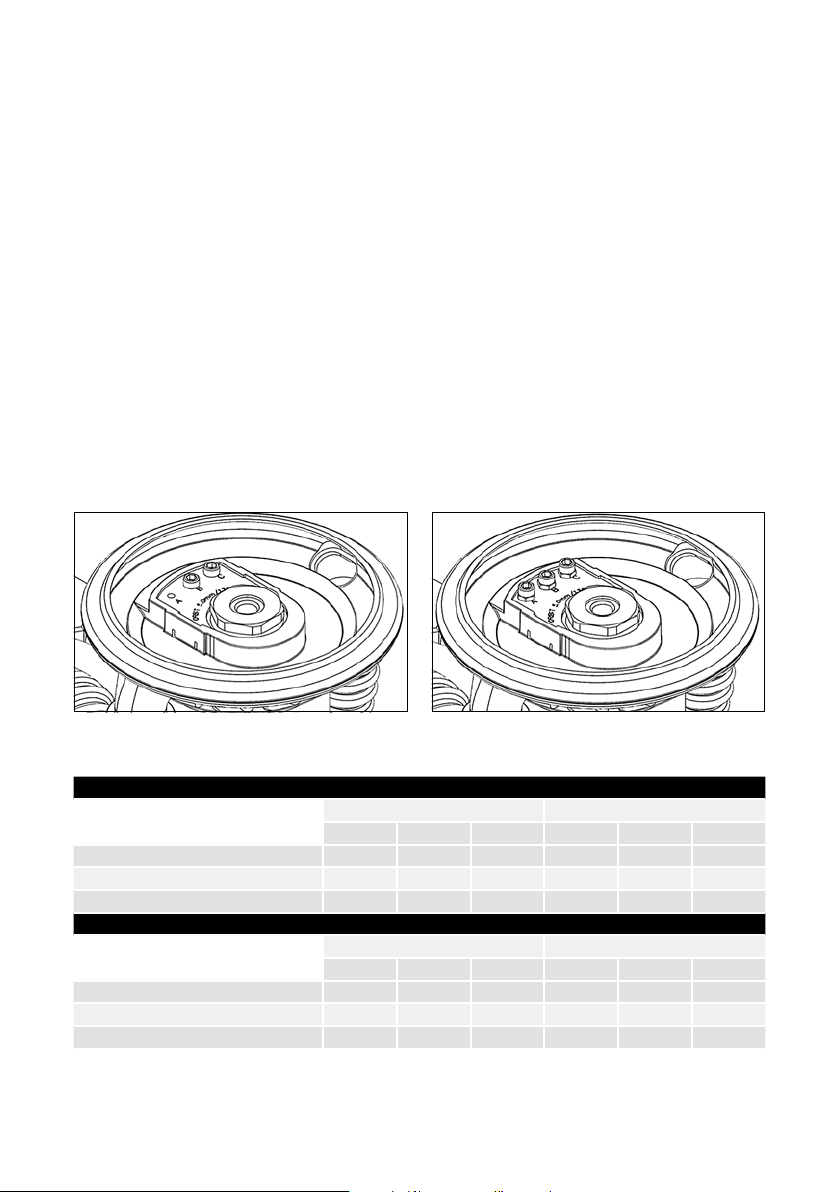

3. All six (6) M8 screw holes should be used to ensure a robust

connection. Note that the pivot pin location is at the front of the tool.

4. On the CV version: Connect the vacuum hose to the tool by fitting the

hose on the exhaust and twisting it counter-clockwise.

5. Connect the power cable to the tool by inserting and twisting the

connector counter-clockwise to the “lock” position.

Interfaces

FLANGE ISO 9409-1-80-6-M8

POWER CONNECTION Phoenix Contact ST-8EP1N8ACK04S

DUST HOSE CONNECTION 25 mm

Declaration of incorporation for partly completed machinery

In accordance with the EU Machinery Directive 2006/42/EC, Annex II, sub.B for partly completed machinery.

Manufacturer: Mirka Ltd

Address: Pensalavägen 210, 66850 Jeppo, Finland

Person established in the community authorised to compile the relevant technical documentation:

Annika Stenmark, Mirka Ltd

Description and identification of the partly completed machinery

Product / article: Mirka® AIROS 77 mm (3"), 125 mm (5") & 150 mm (6")

Type: 350CV, 350NV, 550CV, 550NV, 650CV, 650NV

Function: Grinding head

The following essential requirements of the Machinery Directive 2006/42/EC have been fulfilled:

1.3.2, 1.3.4, 1.3.7, 1.5.1, 1.5.4, 1.5.5, 1.5.9, 1.5.13

The relevant technical documentation is compiled in accordance with part B of Annex VII.

This partly completed machinery is in conformity of the following EU Directives:

EMC- Directive 2014/30/EU, RoHS- Directive 2011/65/EU

Applicable Harmonized Standards: EN 62841-2-4:2014, EN 61800-3:2004+A1:2012

The partly completed machinery must not be put into service until the final machinery into which it is to be

incorporated has been declared in conformity with the provisions of the Machinery Directive 2006/42, where

appropriate.

Jeppo 02.09.2019

Place and date of issue Stefan Sjöberg, CEO

Installing the tool

Connecting

the power

cable