Lintec CV-3000 Series User manual

LN0540E2110B0

Piezo Control Valve

Instruction Manual

CV-3000 Series

Safety Precautions

Incorrect handling may cause death or injury

(1) Before connecting the fittings, check that no damage or defects are found on

the fittings. Make connections properly and make sure that a leak test is

conducted before actual operation to prevent fluid from leaking into the

atmosphere (Hereafter, the measured fluid is called “gas” or “fluid”).

(2) DO NOT apply any corrosive fluid tomaterials exposed to gas. Corrosion may

cause gas to leak into the atmosphere.

(3) This device is not designed as an explosion proof structure. DO NOT use this

device in a place where explosion-proof structures are required. Doing so may

cause fire or explosion.

Incorrecthandlingmaylead tomedium orslight injuryormay

causedamageto,orlossof,facilitiesorequipment

(1) Observe the precautions listed in the WARNING (above).

(2) Strictly observe the electrical specifications. Not doing so may cause fire,

damage to sensors or malfunction.

(3) This device is not designed to be waterproof. DO NOT locate this device

outdoors or in a place where it may besplashed with water.Doing so may cause

fire, trouble, or malfunction of the device.

(4) DO NOT modify this device. It may cause fire or other problems.

(5) While a power supply is applied to the device, +15VDC and -15VDC must be

applied simultaneously. If only +15VDC or -15VDC is applied, electronic

circuits will become unstable and it may cause a malfunction.

(6) This device is not designed to handle hot swap. Please avoid attaching and

removing the power supply connector and interface connector with the power

switched on. Attachment and/or removal with the power on may result in

failure of the device.

(7) This device is a precious device, please handle it carefully. Dropping down or

handling it carelessly will cause damage. Please use assist instrument while

moving or setting the device.

(8) Regular maintenance is recommended for steady use of this device

(Recommended proofreading frequency is once a year).

1. Introduction

This manual explains basic operation of the piezo control valve CV-3000 series

(Hereafter, it is called "CV"). Please read through this manual carefully to

familiarize yourself with the features of this device.

2. Summary

The CV is a high-speed response valve for controlling the flow rate or pressure of

gas by the control input from an external device.

3. Features

The CV is the following features.

(1) Equipped with a high-speed, high-performance piezoelectric actuator.

(2) Superior corrosion resistant sealing materials make maintenance easy.

(3) By using a metal case and various types of filters, steady operation can achieve

even in an environment of high-frequency noise and stationary magnetic field.

(4) RoHS compliant

4. Structure

The CV consists of piezo valve, control circuit, piezo driver.

5. Specification / Dimensions

(1) Specification

Name

Piezo Control Valve

Model

CV-3102

CV-3202

Standard flow rate in

nitrogen

~5LM

~10LM

Valve operation mode

Normally open valve / Normally closed valve

Internal surface treatment

No treatment / Precision polishing (LEP)

Minimumcontrollableflowrate

2%F.S.

Settinginputofvalve-opening

0 to 5VDC

Response time

Less than 0.5 second

Operating differential

pressure

50 to 300kPa(D)

Normally open 50 to 300kPa(D)

Normally closed 100 to 300kPa(D)

Maximum operating

pressure

300kPa(G)

Withstanding pressure

1MPa(G)

Operating / Storage

temperature & Humidity

0 to 50ºC·0 to 80%RH (Condensation should be avoided)

Leak integrity

Less than 1×10-11Pa · m3/sec (He)

Mounting direction

Free

Wetted materials

Stainless steel 316L, PCTFE, Au

Seal Materials

Au

Actuator

Piezoelectric actuator

Fittings

6.35VCR

Power supply

+15VDC±3% : 50mA -15VDC±3% : 50mA

Weight

Approx. 700g

(2) Dimensions

6. Ordering information

CV-3*02 –MO –4VR5 AAA00 –dd –ee –ff

[1] [2] [3] [4] [5] [6] [7]

[1] Series model: CV: Control Valve

CV-3102, CV-3202

[2] Valve mode

NO: Normally open (No treatment), MO: Normally open (LEP)

NC: Normally close (No treatment), MC: Normally close (LEP)

[3] Fitting

4VR5:6.35mm VCR86

※ Please consult for more information.

[4] Optional

Default setting is labeled

“AAA00”.

Please consult for more information.

[5] Gas type

[6] Full scale flow rate

[7] Flow rate unit

CCM, LM

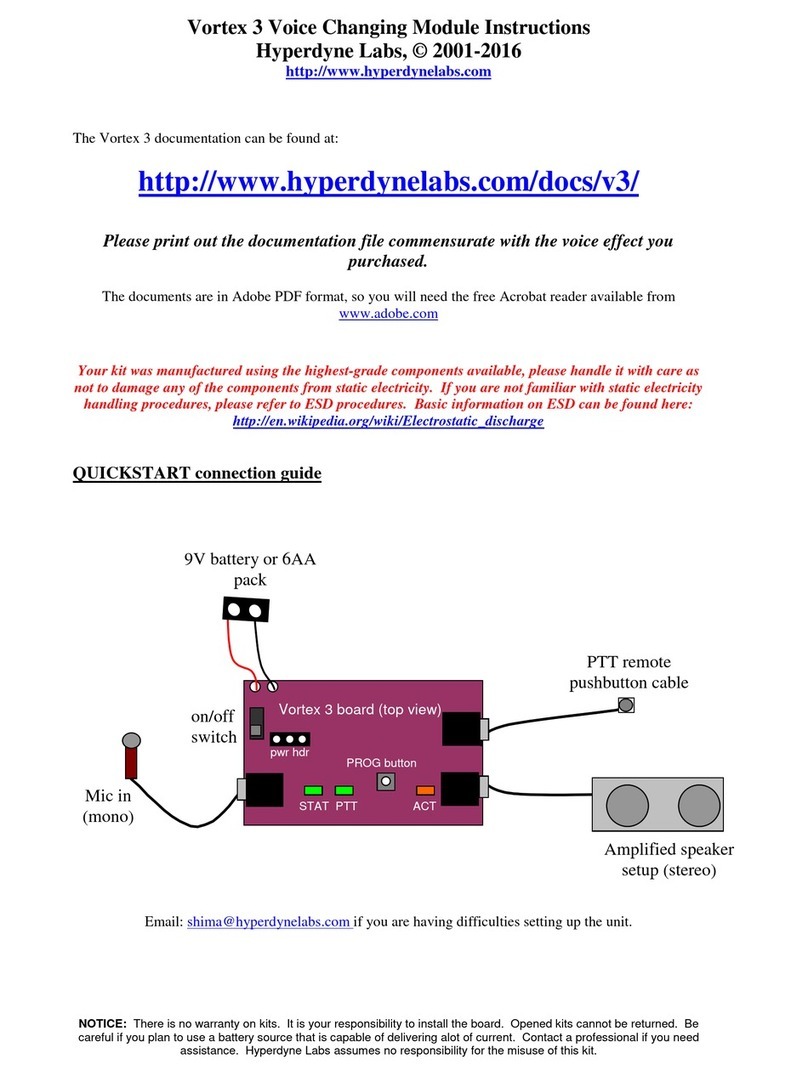

7. Connection

(1) Analog interface connector

Mounted connector : D-Sub 9 pin(male)

Pair connector : D-Sub 9 pin(female) (Fixed size of screw : M3)

Pin No.

Single name

Function

1

Valve on-off input (Note1)

+15VDC: OPEN, -15VDC: CLOSE

2

N.C.

N.C.

3

Power supply input +15VDC±3%

Power supply (plus) 50mA

4

Power supply COMMON

COMMON ±15VDC

5

Power supply input -15VDC±3%

Power supply (minus) 50mA

6

Setting input of valve-opening voltage

(Hi) 0 to 5VDC

Setting voltage plus side 0 to 5VDC

7

N.C.

N.C.

8

Setting input of valve-opening voltage

(Lo) 0 to 5VDC

Setting voltage minus side 0 to 5VDC

9

N.C.

N.C.

Note1)Inputimpedance offlow rate settingsignalis 100kΩ. Valve override impedance is 100kΩ.

·Theinitialflowrate settinginputis thesingle endinputmode. Pleasechangethe sideswitchinto

thelowerpositionwhenyou use the quasi-differentialinputmode.

·Pleasedo notconnectanythingwithN.C..

(2) Input switch

The toggle switch on the side of the CV is the selection switch for changing the

input setting mode. The single end mode is the upper position. The quasi-

differential input mode is the lower position.

1) Quasi-differential input

Use the quasi-differential input mode when both the COMMON of the power

supply and the COMMON of the setting signal make a common. Using the CV

in the single end mode will result in voltage error in the COMMON due to signal

transportation.

2) Single end input

Use the single end mode when both the COMMON terminal of the CV power

supply and the COMMON terminal of the setting signal are in a floating condition.

8. Valve characteristics

(1) Flow rate Characteristics

The relation between the setting voltage and the flow rate of the CV is not linear,

as shown in the figure. Also, the piezoelectric actuator exhibits hysteresis.

Therefore care should be taken if the CV is used in the open-loop mode. The valve

fully closes with zero 0VDC, and fully opens with five 5VDC of the valve setting

voltage, for both normally open and normally closed valves.

(2) Flow range

The maximum flow range isnot accurate. It changesgreatly depending on the type

of fluid, the pressure, and the environmental temperature, etc.

10. Operation

(1) Procedure

1) This product is packed in a clean room before shipment. Please break the

seals in a clean room after taking it out of its box.

2) Check the gas type and flow rate, and check the direction of the gas flow

and the CV before installation.

3) Check for gas leaks from the tubing with a helium (He) leak detector.

4) Connect the interface connectors according to the Connector tale.

5) Power requirements are +15VDC: 50mA and -15VDC: 50mA. Check the

voltage, polarity, and capacitance of the power supply voltage.

6) Turn on power supply and let the equipment warmup for at least 5 minutes

(Recommended time: 30min).

7) Complete shut off cannot be achieved with the CV. If complete shut off is

desired, a shut-off valve should be installed.

8) When a highly reactive gas is used, thoroughly purge all foreign matter

from the tubing and the CV before operation.

9) When contaminated gas is used, install a filter at the equipment inlet.

10)Use the CV within the range of the operating temperature (5 to 50°C).

11)Donotswitchthepowersupplyonandoffwithinonesecond.Itmaycausefailure.

12)When it is used as a feedback control of flow rate and pressure, the operation

output voltage of the PID controller should be 0 to 5 VDC. Choose a device with

output voltage of 0 to 5 VDC.

13)When using the Lintec MFC power supply, the built-in power supply and signal

setting generator make it easy to set up a system like an MFC.

(2) Valve control signal

The CV features a forced valve open/close input function.

The connector pin No.1 is used to input the internal valve open/close signal.

By inputting this signal, a forced opening/closing of the internal valve can be

performed without depending on the value of the flow rate preset signal.

When +15VDC is input: fully open

When –15VDC is input: fully closed.

11. Product warranty

(1) Period

This product is guaranteed for a period of 1 year from date of shipment. Defects

are repaired according to the following regulations.

(2) Scope

Warranty coverage is restricted to this product only. Any other damage caused

by this product is not covered.

(3) Disclaimer facts

The following repairs are not covered by the warranty:

1) Failure caused by by-product of fluid used.

2) Failurecausedbymisuse(includingcarelessoperation)orincorrectrepairormodification.

3) Failure caused by dropping after purchasing.

4) Failure caused by a natural disasters.

Even if the warranty period isstill in effect, the following items may not be repaired.

1) When the kind of fluid used in the product is unclear.

2) The product is returned with fluid remaining inside and safety cannot be

confirmed.

This device is a precision instrument. Control may become unstable if electric

noise, temperature change of fluid, pulsation of fluid pressure etc. occurs.

Please be forewarned.

This instruction manual is subject to revision without notice.

http://www.lintec-mfc.co.jp

CorporateHeadquarters

4-1-23Sekinotsu,OtsuCity,ShigaPref.520-2277,Japan

TEL. +81-(0)77-536-2210FAX.+81-(0)77-536-2215

TokyoBranchOffice

3FHattoriBuild.,4-30-14YotsuyaShinjyuku-kuTokyo160-0004, Japan

TEL. +81-(0)3-5366-2801FAX.+81-(0)3-3341-3513

印加電圧

流量

Setting

Flow rate

This manual suits for next models

2

Other Lintec Control Unit manuals

Popular Control Unit manuals by other brands

Trane

Trane Belimo B2 Series installation instructions

elsner elektronik

elsner elektronik RF-MSG-ST IP54 Technical specifications and installation instructions

Bradley

Bradley S90-252 HFP Adjustment Instructions and Parts List

Seav

Seav LG 2215TC manual

KBR

KBR multisio 1D4-4RO ISO operating instructions

Eaton

Eaton SmartWire-DT SWD Series manual

Toshiba

Toshiba PA912 instruction manual

SP Controls

SP Controls PixiePlus PXE-DCM PLUS installation guide

Nittan

Nittan EVA-SCM-SCI instruction manual

Frequency Central

Frequency Central Looking glass manual

Berthold

Berthold castxpert LB 452 operating manual

ICP DAS USA

ICP DAS USA WISE-5801-MTCP quick start guide