702

(2)

Pre-lubrication - This series is pre-lubricated, so no lubricator

is required. However, once lubrication has been started, it

must be continued so that the lubricant is not used up. For

lubrication, use the turbine oil Class 1 ISO VG32 (#90) or

equivalent.

(3) Filter - Install a filter with a 5 μm or less filter element.

Design & Selection

CR circuit

Triode AC switch

Leakage

current

C

R

Solenoid valve

Programmable

controller side

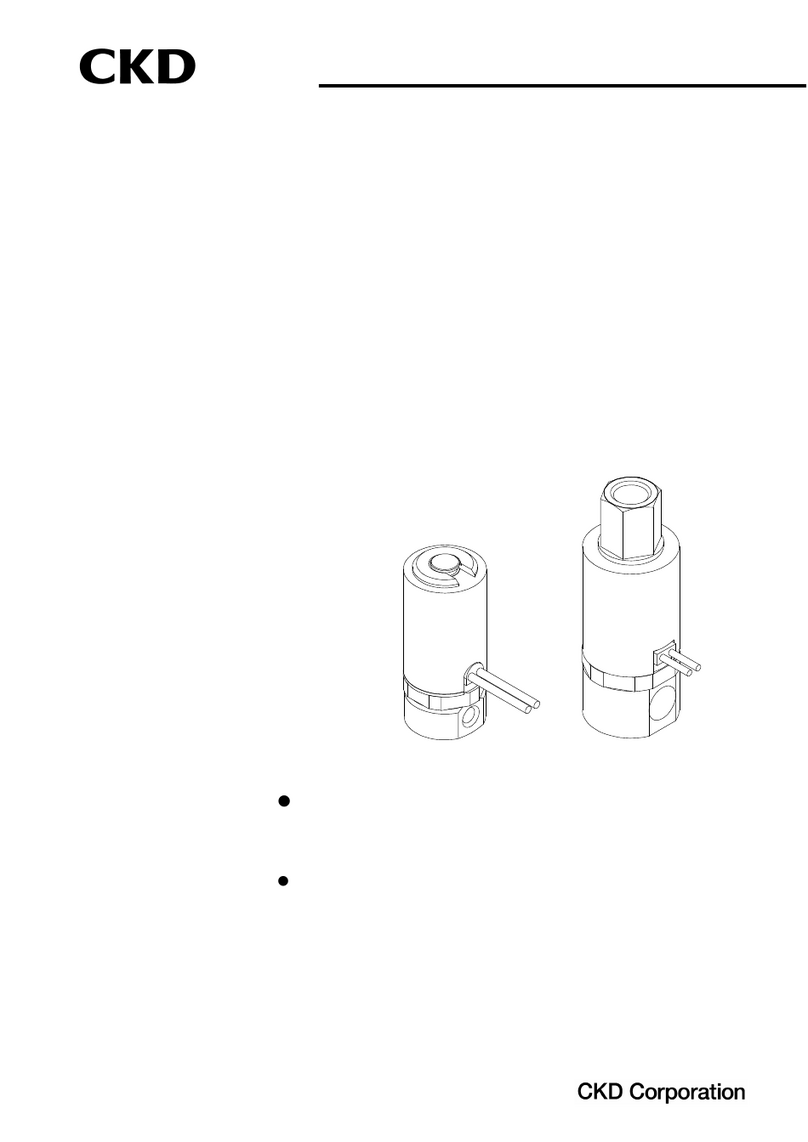

Air operated 2, 3 port valve (coolant valve) (CVE/CVSE)

1. Safety designing

CAUTION

䡵Leakage current from other fluid control components

When operating the solenoid valve with a programmable

controller, etc., check that the output leakage current from the

programmable controller is within the following specifications.

Failure to observe this could lead to malfunctions.

䡵

CVSE Series cannot be used in an explosive gas atmosphere.

When using in an explosive gas atmosphere, change to the

CVE Series, and provide a separate explosion proof solenoid

valve on the pilot air circuit.

䡵If there are high levels of dust in the area, install a downward-

facing silencer or elbow joint on the exhaust port so that dust

does not enter.

䡵

When using in a place where water splashes on the valve, take

appropriate measures to protect it.

WARNING

2. Working fluid

WARNING

3. Working environment

4. How to use

䡵Working fluid

The compatibility has not been evaluated with all coolants.

Particularly, if coolant contains high levels of chlorine or

sulfur, materials used at wetted parts could be adversely

affected. Confirm the compatibility when making a selection.

Non-corrosive fluids refer to fluids that do not affect or are not

affected when they contact the valve's wetted part materials.

cast iron (nickel plating), stainless

steel, nitrile rubber or fluoro rubber,

and epoxy resin adhesive.

䡵External pilot air

(1) Drainage measures - Compressed air contains high levels

of drainage (water, oxidized oil, tar, foreign matter) that

can significantly reduce the reliability of pneumatic

components. As measures against drain, improve air

quality by dehumidifying with an after cooler or dryer,

removing foreign matter with a filter, and removing tar with

a tar removal filter, etc.

CAUTION

䡵Pilot air pressure

Use pilot air pressure in accordance with the specifications.

X

Y

P

Y

P

IN

Model no.

CVE2

CVE22

CVSE2/CVSE22

CVE3

CVSE3

Pilot operation

side supply port

Unit side

supply port

Note: Pipe the unit side supply port so that the arrow on the body matches

the fluid flow direction. If supplied in reverse, internal components

could be damaged when the valve operates.

CAUTION

1. Piping

䡵Do not pipe using the solenoid valve section. There is a risk

of damage. (For solenoid valve mounted type)

Installation & Adjustment

䡵When piping the CVE or CVSE Series, pay attention to the

supply ports on the unit and pilot operation sides.

Wetted part materials:

100 VAC : 3 mA or less

200 VAC : 1.5 mA or less

24 VDC : 1 mA or less

must be maintained.

Safety precautions

Always read this section before starting use.