HCS GDC D1 TECHNICAL DESCRIPTION

APRIL 2019

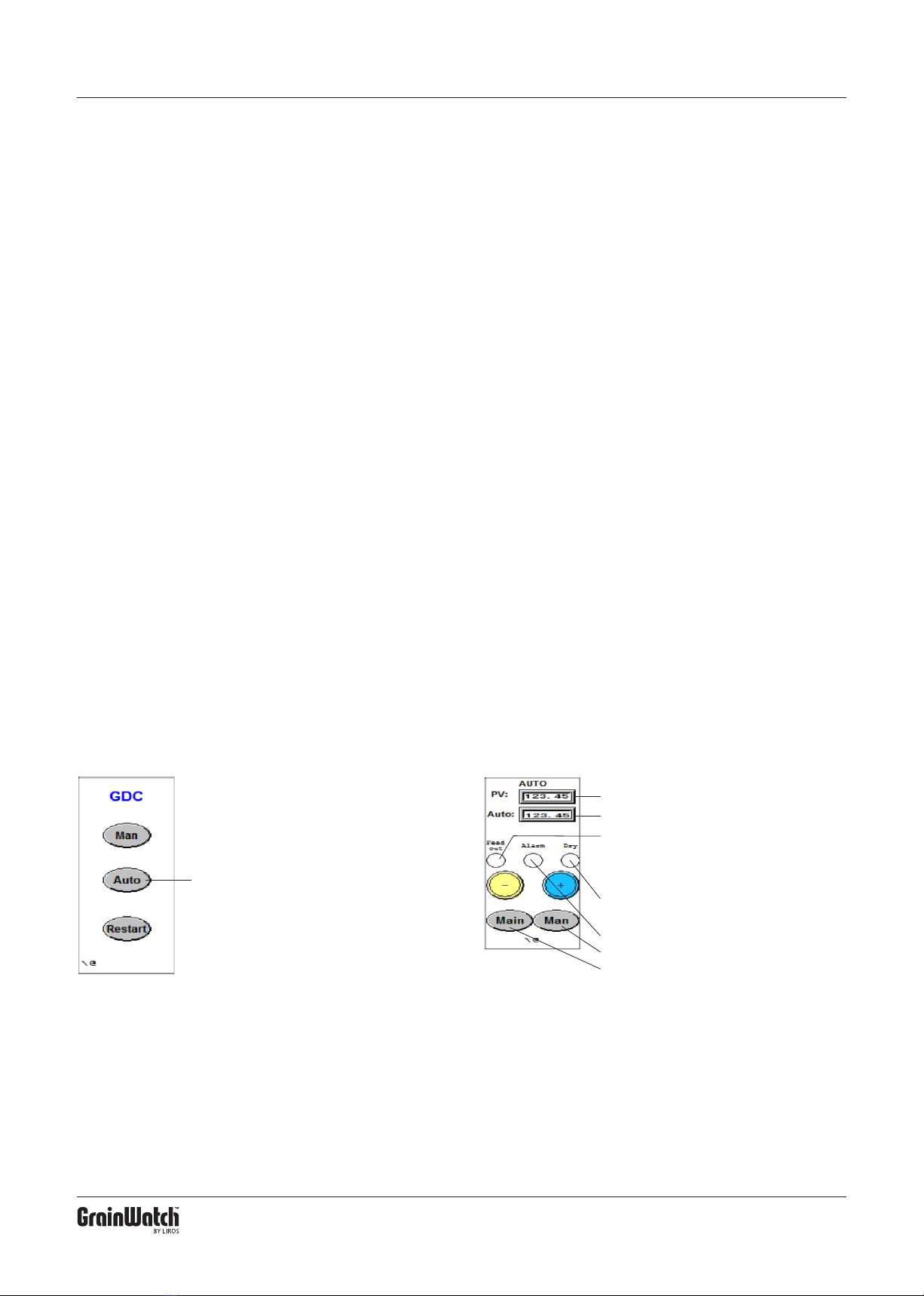

3. Auto Mode

5

With Auto mode, the control is given a value from the

transducer displayed in the “PV” box. The value is dif-

ferent for different types of cereals with the same mois-

ture content and changes according to the moisture

level of the cereals. Dry commodity = low value, wet

commodity = high value.

The Auto value setting is made either of an earlier

value used for the grain in the dryer, or from the “Auto-

Set” in a previous manual run (see chapter 2).

If, when checked, the water content is not the de-

sired, the autovalue can be changed with the plus and

minus buttons (Plus = higher value, wetter commodity,

Minus= lower value, drier commodity). However, never

change the autovalue more than 0.20 at a time.

After resetting values, let the dryer go for at least one

hour. Then check that the adjustments support the

desired result.

Normally, the Auto value should be between 5.00-

8.00 – Lowest value for dry commodity (oil seeds) or

commodity with a lot of shell (oats). Highest value for

wet commodity with little shell (wheat).

Feed Auto is lit when output is active. The output

time is normally 27 secs but it can be changed to 18

secs to get closer feedouts with less content each time.

Alarms are activated when the equipment has

made 6 feedouts on the longest drying time without

lowering the water content. When alarms are activated,

no further ejections are made.

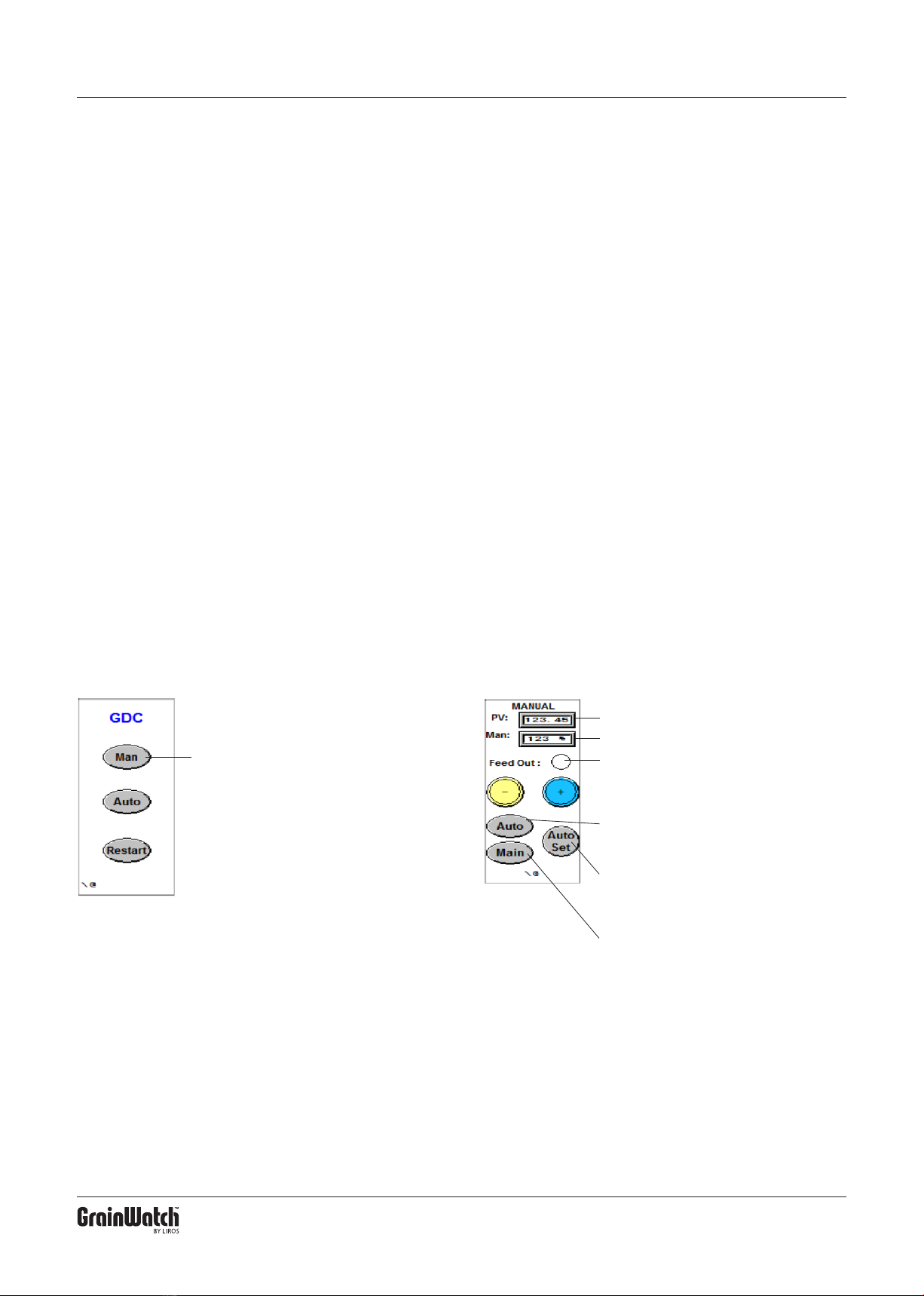

Press “Auto”

Step 1

PV: Shows the signal from the sensor.

Man: Shows the percentage set.

Feed Out: Lights up yellow when output is

active.

–: Decreases the set percentage (drier item).

+: Increases the set percentage (wetter item).

Dry: Lights up Green when the commodity is

drier than the set value.

Alarm: Red light when alarm is activated.

Man: To go to Manual mode.

Main: To go to Home screen.

Step 2