4. Preliminary checks

6

Manually bring the gate to a total opening position and

check the status of led LSC.

Once all above operations are successfully terminated, close

the automation and lock the motor.

2

1

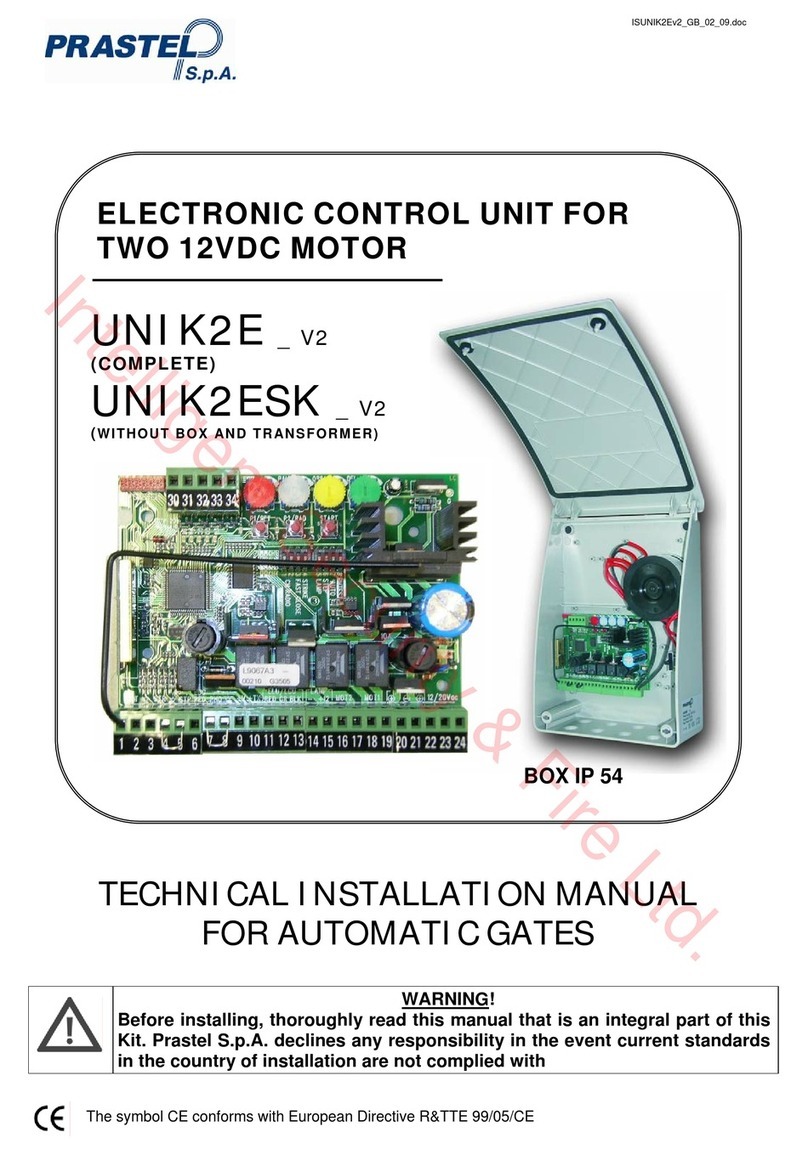

The preliminary checks must be carried out only by professionals and by paying maximum attention. The correct wiring of the motor and the limit

switches is very important for the correct functioning of the automation.

Unlock the motor and supply the system with power only

after controlling the wiring connections and checking the

absence of short circuits.

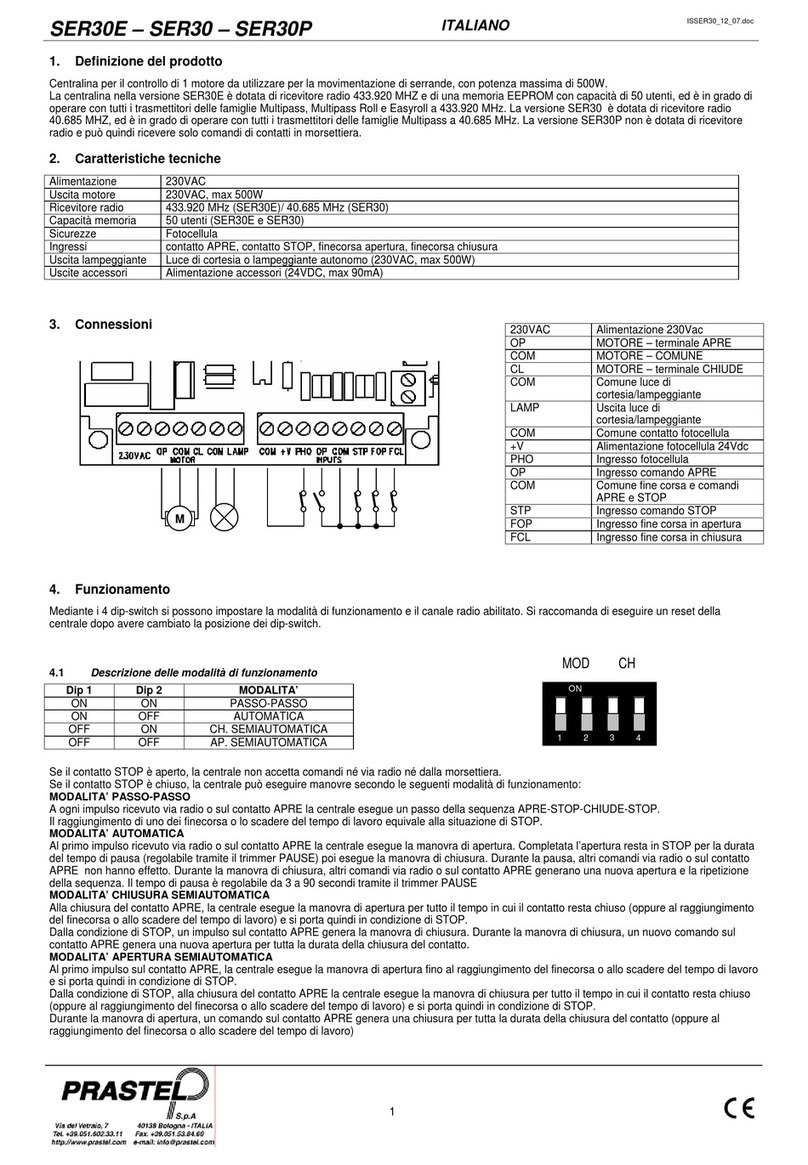

Check the status of the LEDs input by considering that all

normally closed (NC) inputs must have their corresponding

led alighted.

Led LSC is off. Correct functioning

Led LSC is on, but led LSC is off; check the connection

of the limit switches.

Manually bring the gate to a total closing position and

check the status of led LSC.

3

Led LSC is off. Correct functioning.

Led LSC is on, but led LSC is off; check the connection

of the limit switches.

Manually bring the gate to the middle of the run and then

lock the motor.

Enter the parameter Manual Movement of MENU B and

command the closure of the gate.

WARNING: pay attention with the moving gate!

4

The motor starts to move. Watch its sense of rotation:

If the gate opens, then stop the manual motion,

disconnect the system from the power and reverse the

motor connections. Then try again.

If the gate closes, then stop the manual motion and go to

the following phase

Enter the parameter Manual Movement of MENU B and

command the opening of the gate.

WARNING: pay attention with the moving gate!

5

The motor starts to move. Watch its sense of rotation:

If the gate closes, then stop the manual motion,

disconnect the system from the power and reverse the

motor connections. Then try again.

If the gate opens, then stop the manual motion and go to

the following phase

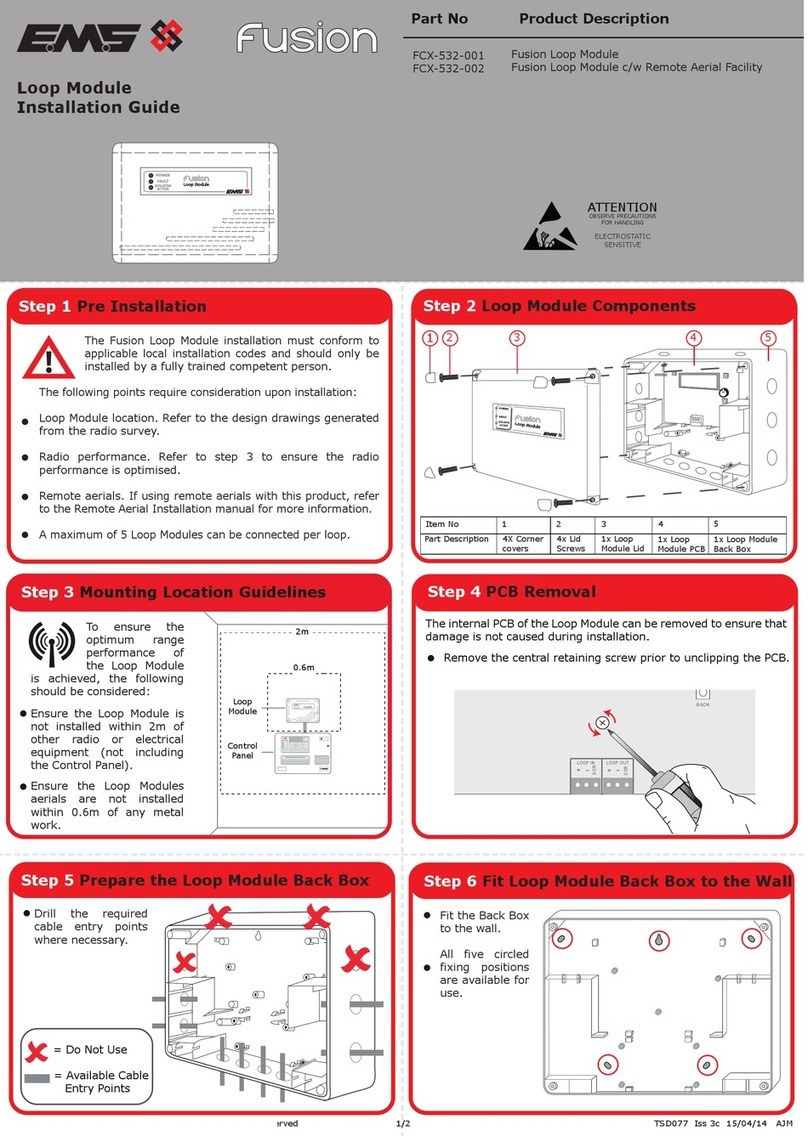

5. Manual motion (Menu B - Manual movement)

This operation must be carried-out only by qualified personnel and by paying maximum attention.

The manual motion is an operation planned only for the phase of installation; it allows to move the gate at a limited speed in both directions.

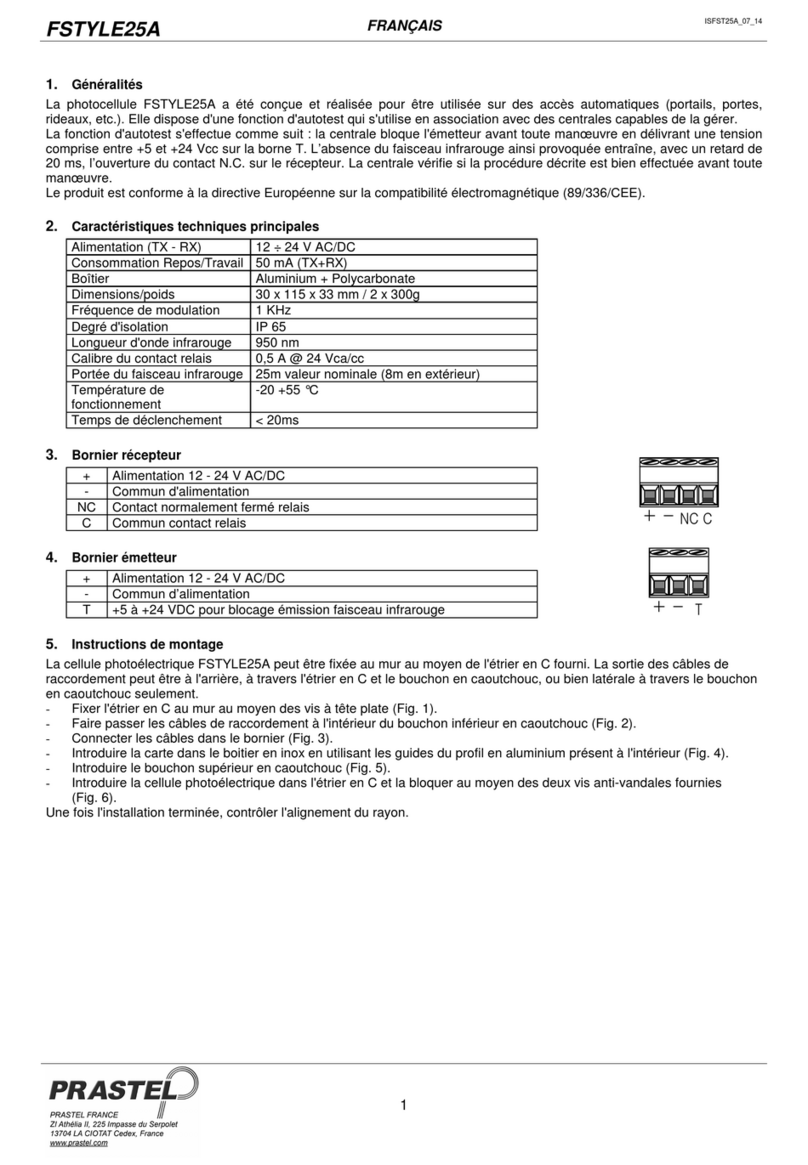

WARNING: the photocells and the safety edge are not monitored during this phase!

Access to parameter Manual Mov. of MENU

B and confirm by pressing key P2. Move the gate by using keys P1 and P3.

Press key P2 or wait 15 sec. in order to exit the menu.

6. Learning

Learning the run allows to define the parameters of the run of the gate, such as the width of the run at normal speed and at slowed speed.

Check that the adjustment of the torque and the speed of the gate are set before carrying out the learning phase.

Check that the gate is closed before starting the learning phase.

Be sure that the limit switches are connected and correctly adjusted.

6.1 Learning the run of the gate (Menu B - Final position)

Enter the parameter Final Position of MENU

B and confirm by pushing key P2.

Start moving the gate by pressing and releasing key P1 (START) or a Step-

by-Step key.

Push key P1 (START) or a Step-by-Step key when the gate reaches the

point where you want to start the slowdown in the opening phase.

The gate continues its run at reduced speed as far as it hits the opening

limit.

Once the opening limit has been reached, the gate starts to close.

Push key P1 (START) or a Step-by-Step key when the gate reaches the

point where you want to start the slowdown in the closing phase.

The gate continues its run at reduced speed as far as it hits the closing limit.

The programming is terminated once the closing limit is reached.

Note: in case no slowdown zones are set, then the control unit follows the

factory settings.

Exit the menu by scrolling the entries until you

find EXIT.

WARNING! Before executing the learning of the strokes, it is advisable to disable the safety devices by means of dip

switches, by moving them to the ON position. This avoids involuntary interventions of the safety devices during the

learning phases.