6 (10)

Adjustment

As the LK Minishunt M60n is intended for con-

nection to existing heating systems, the available

drive pressure and ow on the primary side are

often unknown. Without this information the

theoretical adjustment values of the minishunt

cannot be calculated. Adjustment should then be

carried out as described below.

If the available drive pressure and ow on the

primary side are known, the theoretical adjust-

ment for the minishunt can be calculated, refer

to the Project planning and design guidance for

LK Underoor heating.

1. Carry out air bleeding of the oor heating

system and the minishunt, as shown above.

2. Start the circulation pump. Upon start up,

use the pump's automatic venting routine

to remove accumulated air in the pump.

The automatic venting routine starts after 3

seconds and proceeds for 10 min. The ven-

ting routine is indicated with a fast ashing

green diode light.

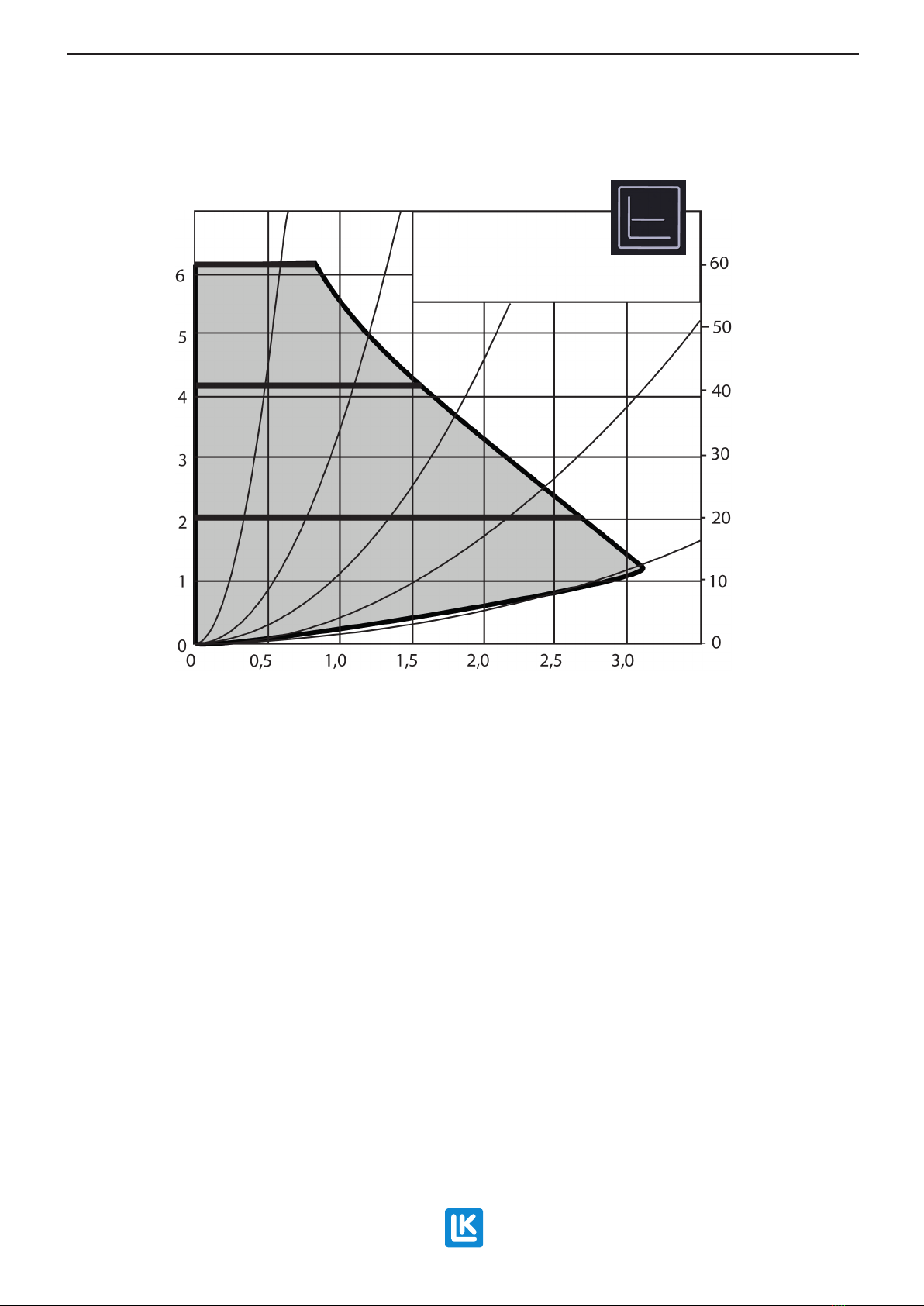

After completing the venting process, the

constant pressure curve that best matches

the requirements of the system is chosen,

see the capacity chart.

3. Set the switch 2/1 pos. 18 for single or twin

pipe radiator systems (twin pipe radiator

system is factory set at delivery). For single

pipe systems the valve is gradually ope-

ned until the correct heating capacity and

temperature is achieved to the following

radiators.

4. Set the primary temperature from the hea-

ting source to the minishunt temporarily to

approx. 55 °C.

5. Set the temperature limiter TEMP to pos. 12

in accordance with the table below. Normal

setting is about 45 ºC.

6. Set the thermostat valve pos. 4 in accord-

ance with the table below.

7. Allow the system to stabilise for about 10

min. The feed temperature should now be

35-45 ºC.

NOTE!

If the temperature is too low, see

Troubleshooting. Note that at start up a

system in an unheated concrete slab,

can take up to 24 hours before the feed

temperature has reached the correct level.

NOTE!

If the temperature is too high, adjust

the feed temperature using the temperature

limiter pos.12 in accordance with the table

below.

8. Finish by resetting the primary temperature

from the heat source to normal temperature.

Settings for the temperature limiter (TEMP)

For limiting the feed temperature for underoor

heating.

Settings for the tempera-

ture limiter (TEMP)

Max. temperature

0 22 ºC

1 25 ºC

2 35 ºC

3 40 ºC

4 45 ºC

5 55 ºC

Settings for the thermostat with a capillary

tube connected sensor

Settings for the thermo-

stat

Room temperature

1 8 ºC

2 14 ºC

3 20 ºC

4 26 ºC

5 32 ºC

Circulation pump

The circulation pump has automatic speed con-

trol, which reduces power consumption and gi-

ves a quieter operation as the pump adjusts the

ow according to the requirements of the system.

A cast arrow on the pump housing indicates the

direction of the ow.

EN.33.C.204.2022-02-10

Assembly instructions | LK Minishunt M60n