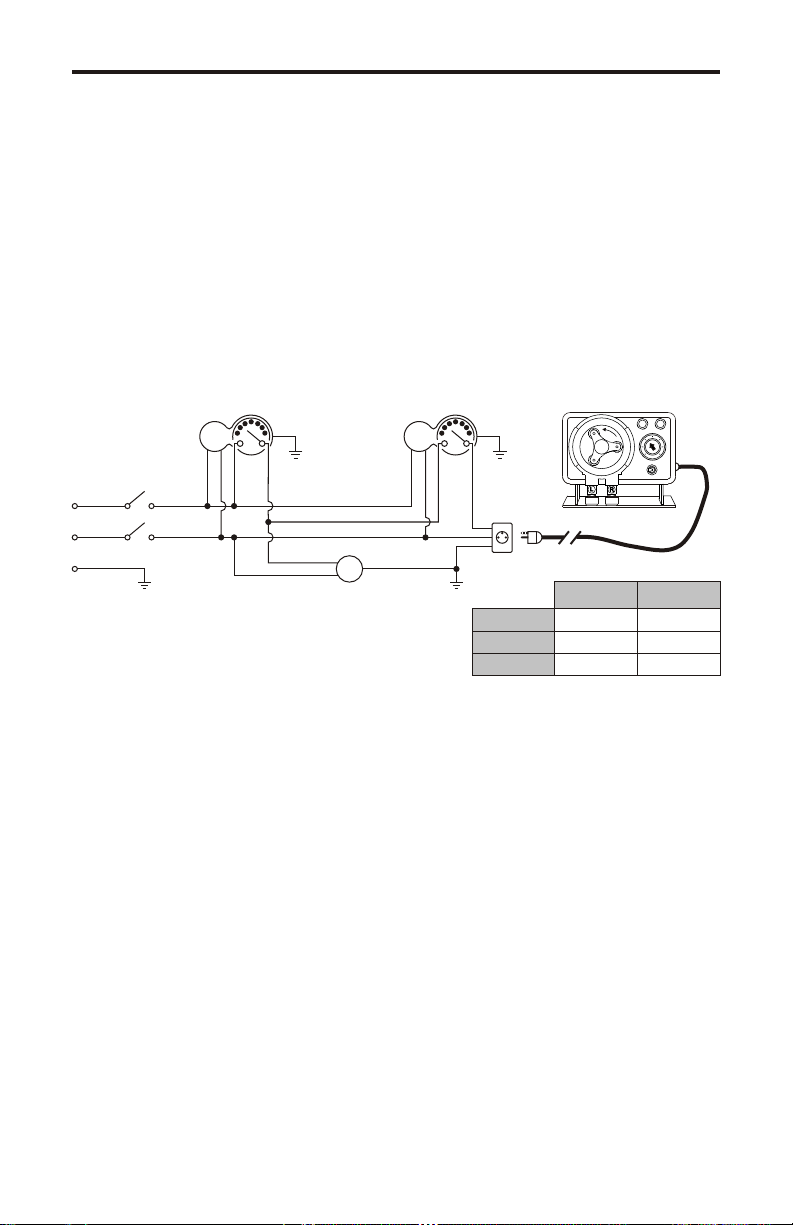

ELECTRICAL REQUIREMENTS

- Be certain you connect the unit to the proper power supply.

- Using incorrect voltage will cause server damage to the motor.

- The voltage requirement is printed on the serial number label.

- All pump models are supplied with a junction box and cover.

- To reduce the risk of electric shock, be certain that a grounding conductor is

connected to the green grounding located inside the junction box.

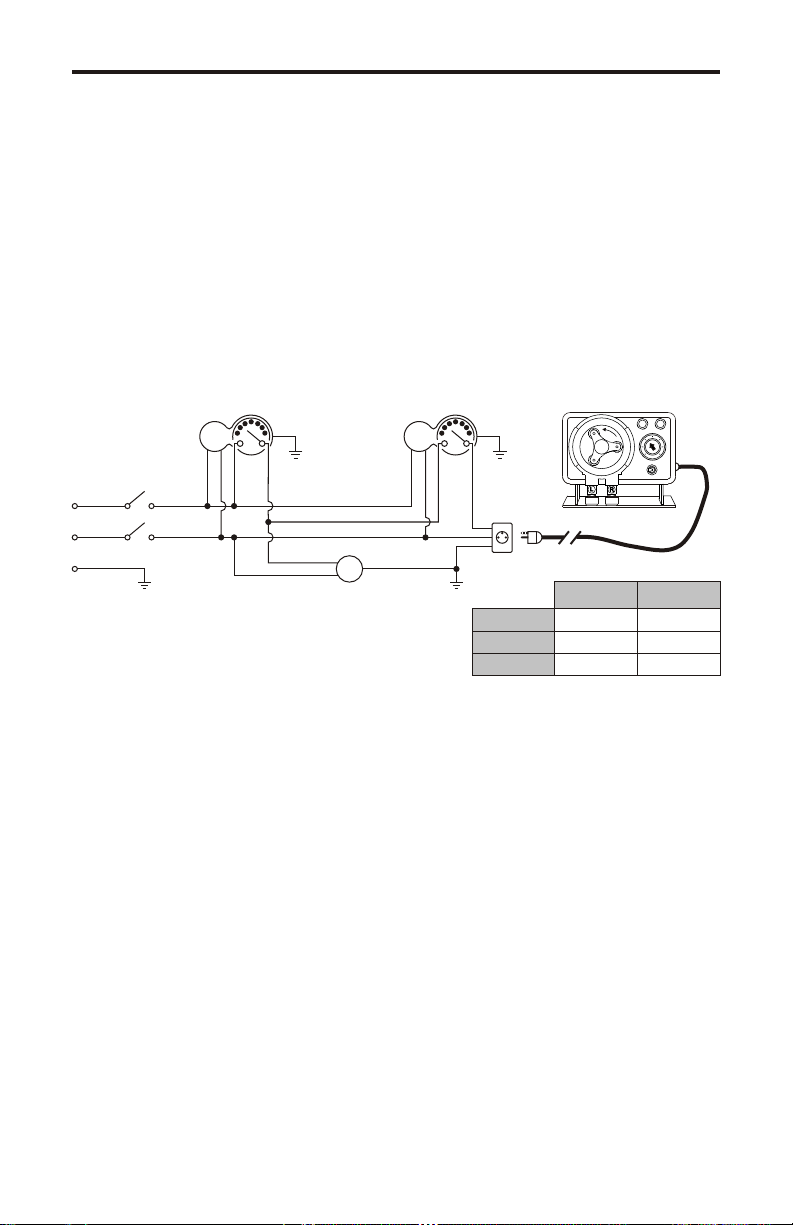

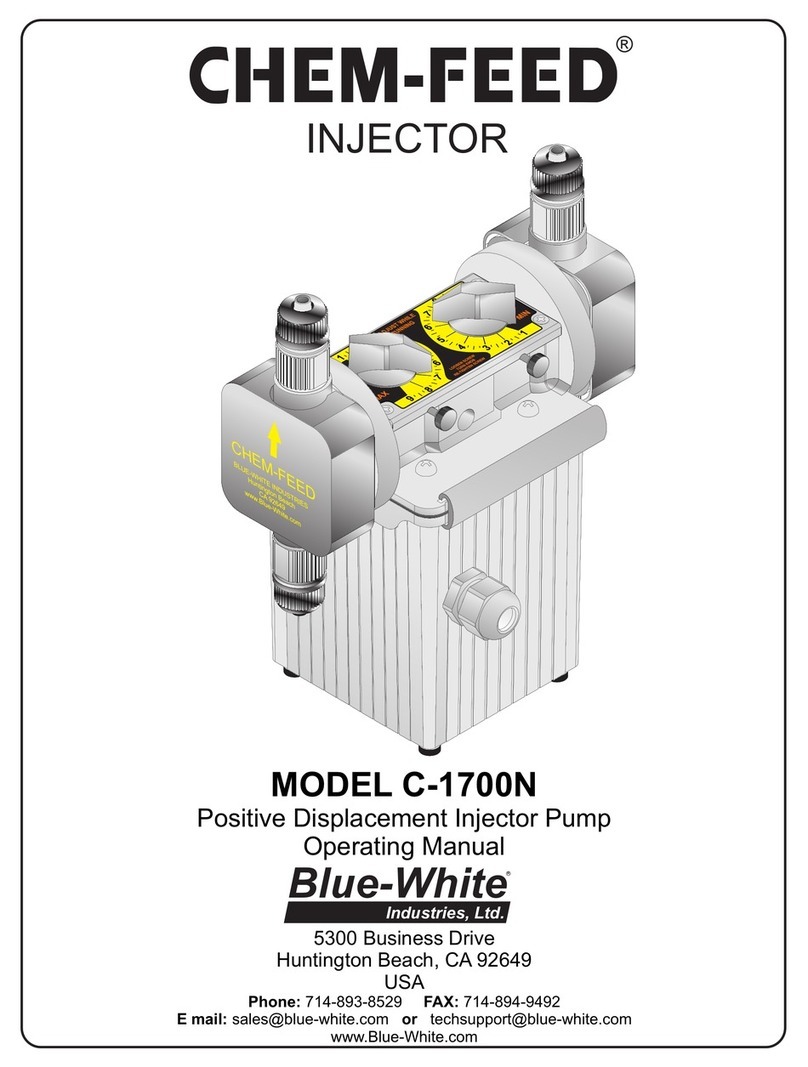

The electrical hook up is very important to operation. The injector must never

operate when treated line is shut down. The diagram above shows th injector

wired within a cycle of a circulation pump or any system where chemical is

used within a cycle but does or does not run al full system. If your system is

complicated, be sure your electrician knows what is required. Remember

chemicals fed to a stopped system can ruin it.

The pump is designed to perform in a wide variety of installations. However, the

service life of the pump will vary, depending on many factors such as; fluid ,

temperature, pressure, etc. Because of the wide variety of installations, the pump

has been factory tested for pressure and performance using water only. Do not

use chemicals if you are not satisfied they are compatible with the pumps

construction.

The pump tube assemblies are designed for maximum service life. However, the

service life can be adversely affected by the chemicals used, the amount of back

pressure, the motor R.P.M., and temperature.

The pump tube assemble should be inspected frequently. Replace the tube if any

cracking, leaking or loss of feed rate occurs.

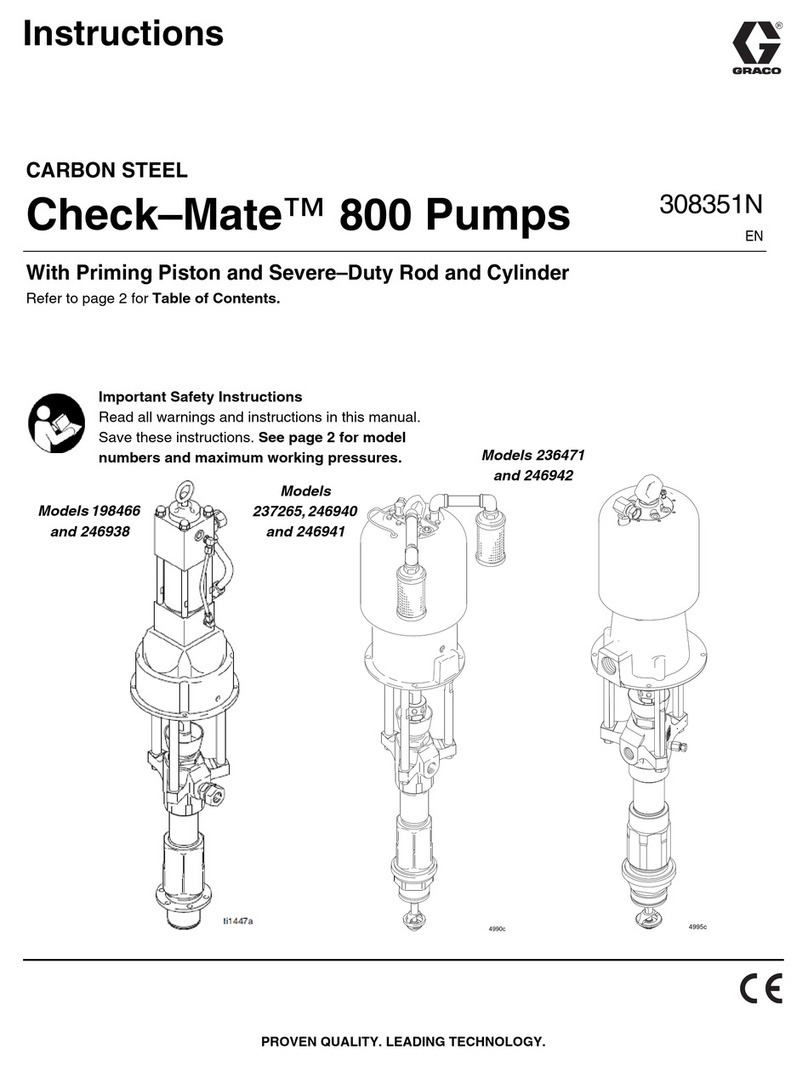

THREADLESS AND THREADED INJECTORS

The most common problem is calcium and/or lime build up inside the injector, foot valve

and tubing. This is basic material and can easily be removed by running a weak

solution of muriatic acid through it. After flushing the pump with clear water, place the

injector filling and foot valve with the tubing attached in a container of weak (1-5)

solution of commercial grade muriatic, them pump it around and around. After flushing

out the wetted parts with clear water again, return pump to service. CAUTION do not

allow acid and chlorine products to come together. This is VERY DANGEROUS to your

health!

OUTPUT ADJUSTMENTS

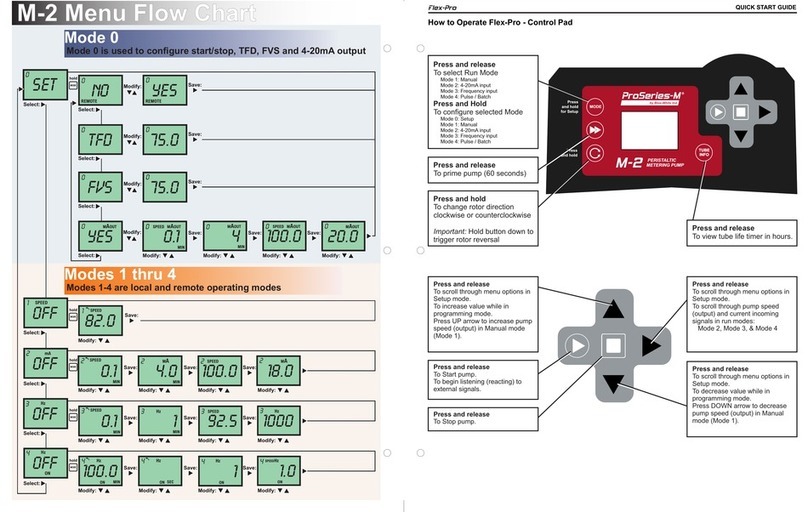

The pause control knob adjusts the cycle timer’s time on. The model A-100 standard

cycle timer is set at one minute. Other cycle lengths are available. To adjust the

amount of time on, turn the pause control knob to the correct setting. ½ equals

approximately 30 seconds on. 3/4 equals approximately 45 seconds on, etc.

MEASURING THE OUTPUT

SUPPLY TANK FOR CHEMICALS

Plastic containers must be designed and manufactured for this purpose. Your

container must be designed for whatever chemical you are using. Do not

place the container in direct sunlight. Ultraviolet (UV) rays attack many

materials which can cause them to become brittle.

OPERATION - MAINTENANCE

Once every week inspect tubing, and accessory valves and fittings. Inspect

all parts for signs of leaks, swelling, cracking, corrosion or discoloration. Also,

inspect the tubing for elasticity.

Cracking, crazing, discoloration, etc., during the first week of operation are

signs of severe chemical attack. If this occurs, immediately remove the fluid

from the injector. Determine which parts are being attacked and replace with

parts that have been manufactured using more suitable material.

NOTE: Sketches and Diagrams for information only. Qualified personnel,

must be used when altering the electrical cord in any way. Qualified

personnel, must also be used for installation of mechanical connections.

Injector

Common

Hot

Ground

M M

M

Time Clocks

Breaker

Switches

Ground

Circulation

Pump

Injector Motor Wire Color Code

HOT

COMMON

GROUND

Black

White

Green

Brown

Blue

Green-Yellow

USA

115V 60HZ

Europe

220V 50HZ

Note: On CE models, wiring will have

double pole - single throw switches

A-100 Page 4 A-100

Page 5

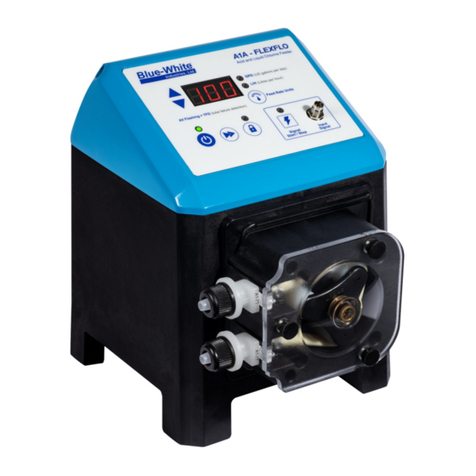

RECOMMENDTUBECHANGE WHEN DISPLAY BLINKS

ADJUSTMENT

CYCLETIME

TUBELIFEWARNING TIMER

RESET

99SEC.CYCLE

PRIME

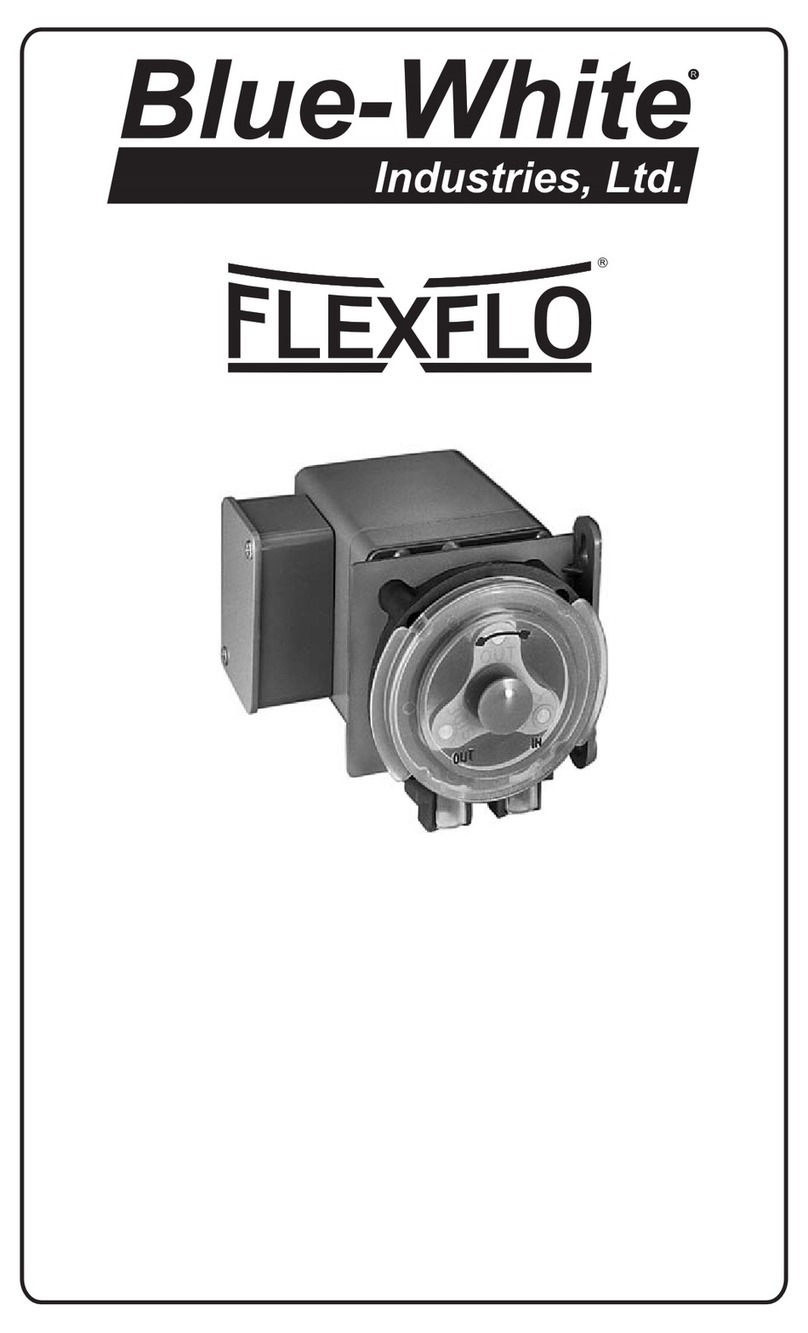

Suction

Tubing

Discharge

Tubing

Graduated

Container

(not provided)

Blue-White

Injection Fitting

Pump

Blue-WhiteR

This volumetric test will take into account

installation factors such as line pressure,

fluid velocity, specific gravity, etc. This

test is the most accurate for measuring

the injector’s output in an individual

installation.

1. With the injector installed under

normal operating conditions, place the

foot valve/strainer in a large graduated

container.

2. Fill the container with the chemical to

be injected and run the unit until all air is

removed from the suction line.

3. Refill the container, if necessary, and

with the foot valve in the solution, not the

amount of chemical in the container.

4. Run the injector for a measured

amount of time and note the amount of

chemical injected.