䕺Be sure to read the following Important Safety Instructions carefully and make sure that you

understand them thoroughly before using this machine.

䠎

ᴾᴾᾀᵌᵲᶆᶃᴾᵿᶇᶐᴾᶎᶐᶃᶑᶑᶓᶐᶃᴾᶑᶆᶍᶓᶊᶂᴾᶀᶃᴾᶉᶃᶎᶒᴾᶕᶇᶒᶆᶇᶌᴾᶒᶆᶃᴾᶐᵿᶌᶅᶃᴾᶍᶄᴾᵎᵌᵓᴾᶒᶍᴾᵎᵌᵔᴾᵫᵮᵿᵌ

䞉If an air pressure which is greater than this is used, the machine may become damaged,

and injury or damage to property may result.

ᴾᴾᾁᵌᵟᶊᶕᵿᶗᶑᴾᶕᶃᵿᶐᴾᶎᶐᶍᶒᶃᶁᶒᶇᶔᶃᴾᶅᶍᶅᶅᶊᶃᶑᴾᶕᶆᶇᶊᶃᴾᶗᶍᶓᴾᶓᶑᶃᴾᶒᶆᶃᴾᶋᵿᶁᶆᶇᶌᶃᵌᴾᴾ

䞉The rivets may jump out by accident and cause injuries (e.g. blindness).

䞉Use a dust mask, safety shoes, hard hat and hearing protector appropriately to prevent

accidents and injuries.

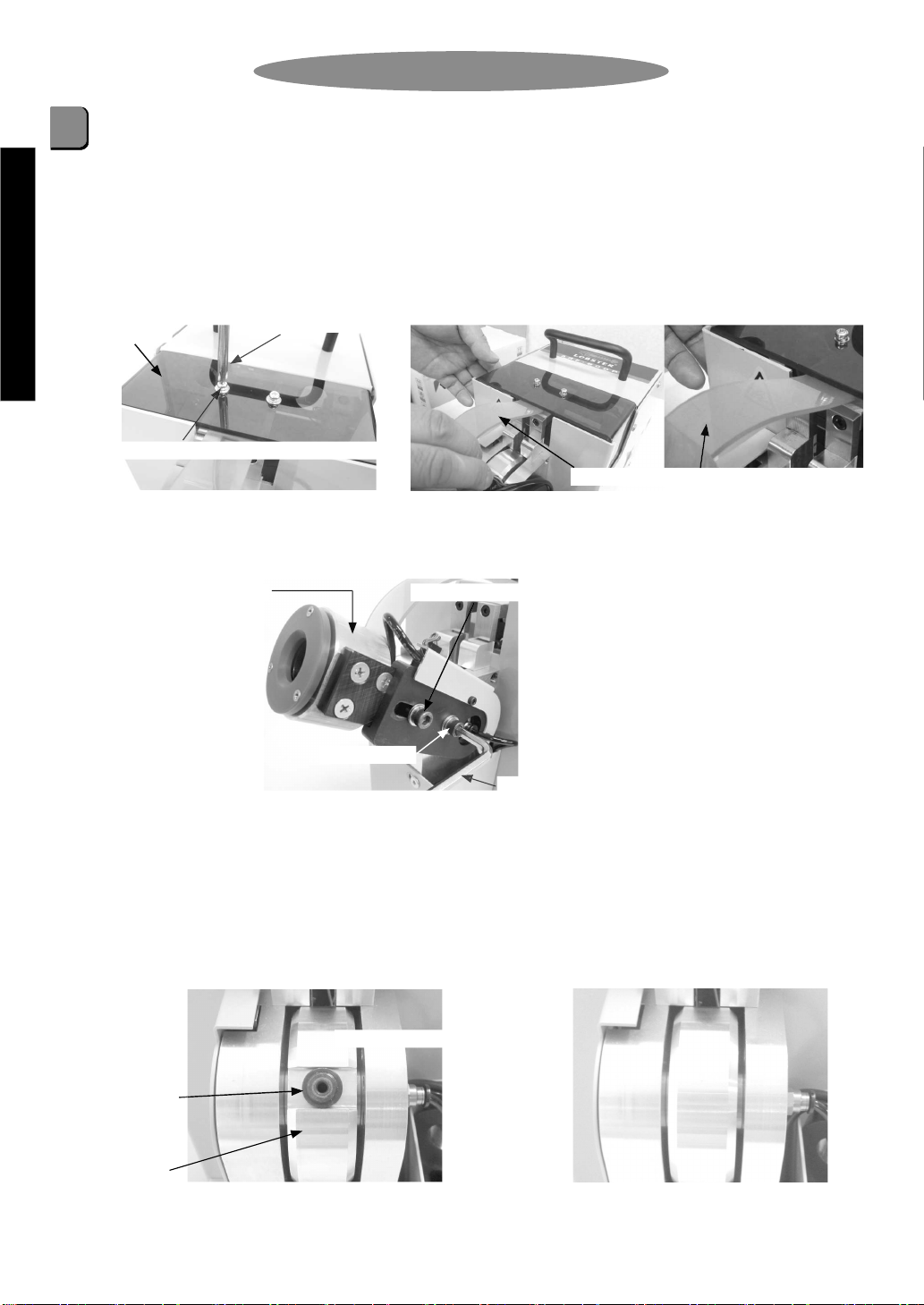

ᴾᴾᾂᵌᵫᵿᶉᶃᴾᶑᶓᶐᶃᴾᶒᶆᵿᶒᴾᶒᶆᶃᴾᶋᵿᶁᶆᶇᶌᶃᴾᵿᶌᶂᴾᶒᶆᶃᴾᵿᶇᶐᴾᶑᶍᶓᶐᶁᶃᵊᴾᶎᶍᶕᶃᶐᴾᶁᵿᶀᶊᶃᴾᵿᶐᶃᴾᶁᶍᶌᶌᶃᶁᶒᶃᶂᴾᶑᶃᶁᶓᶐᶃᶊᶗᵌ

䞉Insert the air tube into the inner side of the air joint of the air supply port securely before

use, or the air tube may become disconnected during use, leading to injuries.ᴾ

䞉Use hose bands to securely connect the air hose joint and air hose. If they are not securely

connected, the air hose may become disconnected during use and injury may result.

ᴾᴾᾃᵌᵲᶓᶐᶌᴾᶍᶄᶄᴾᶒᶆᶃᴾᵿᶇᶐᴾᶑᶓᶎᶎᶊᶗᴾᶀᶃᶄᶍᶐᶃᴾᶂᶇᶑᶁᶍᶌᶌᶃᶁᶒᶇᶌᶅᴾᶒᶆᶃᴾᶋᵿᶁᶆᶇᶌᶃᴾᶄᶐᶍᶋᴾᶒᶆᶃᴾᵿᶇᶐᴾᶑᶍᶓᶐᶁᶃᵌ

䞉Compressed air may cause the air hose to whip around and injury may result.

ᴾᴾᾄᵌᵮᶐᶇᶍᶐᴾᶒᶍᴾᶓᶑᶃᵊᴾᶁᶆᶃᶁᶉᴾᶄᶍᶐᴾᶂᵿᶋᵿᶅᶃᴾᶒᶍᴾᶐᶃᶑᶎᶃᶁᶒᶇᶔᶃᴾᶎᵿᶐᶒᶑᵊᴾᵿᶌᶂᴾᶃᶌᶑᶓᶐᶃᴾᶒᶆᵿᶒᴾᵿᶊᶊᴾᶎᵿᶐᶒᶑᴾᵿᶐᶃᴾᵿᶀᶊᶃᴾᶒᶍᴾᶍᶎᶃᶐᵿᶒᶃᴾ

ẅᴾᴾᶌᶍᶐᶋᵿᶊᶊᶗᴾᵿᶌᶂᴾᶎᶐᶍᶔᶇᶂᶃᴾᶒᶆᶃᴾᶄᶓᶌᶁᶒᶇᶍᶌᶑᴾᶑᶎᶃᶁᶇᶄᶇᶃᶂᵌᴾᵧᶄᴾᶒᶆᶃᶗᴾᵿᶐᶃᴾᶓᶌᵿᶀᶊᶃᴾᶒᶍᴾᶍᶎᶃᶐᵿᶒᶃᴾᶌᶍᶐᶋᵿᶊᶊᶗᴾᶍᶐᴾᶎᶐᶍᶔᶇᶂᶃᴾᴾᴾᴾ

ᴾᴾᴾᴾᶒᶆᶃᴾᶄᶓᶌᶁᶒᶇᶍᶌᶑᴾᶑᶎᶃᶁᶇᶄᶇᶃᶂᵊᴾᶂᶍᴾᶌᶍᶒᴾᶓᶑᶃᴾᶒᶆᶃᶋᵊᴾᶀᶓᶒᴾᵿᶐᶐᵿᶌᶅᶃᴾᶄᶍᶐᴾᵿᴾᶐᶃᶎᵿᶇᶐᴾᶀᶗᴾᵿᴾᶁᶍᶋᶎᶃᶒᶃᶌᶒᴾᶎᶃᶐᶑᶍᶌᵌᴾᴾᴾ

䞉If the machine is used while any parts are damaged, injury may result.

䞉If the machine is damaged by objects being dropped onto it, the damaged part may break

and accident or injury may result.

䞉When replacing or cleaning parts, observe the instructions in the instruction manual.

If you cannot !nd the relevant instructions in the manual, arrange to have the repair carried

out by the supplier you purchased the product from, or by Lobtex.

䞉If there is no power to the equipment even though the power switch is turned on, or the

machine cannot be started when the start button is pressed, do not use the machine.

Otherwise, it may operate abnormally, causing injuries.

䕺Do not put your hands in the machine or close to the moving parts while you are using the

machine. Otherwise your hand may be caught and injury may result.

ᒍᛖᾔᾝᾖᾛᾘᾢᾗ

⅐ ※‿⁂⁁⁄⁆″⁀⁆‒⁅″‸‷⁆⁋‒※⁀⁅⁆⁄⁇‵⁆※⁁⁀⁅

䕺After reading this manual, keep it in a safe place where it is easily accessible to machine users.

䕺This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

䚷Obey all safety messages that follow this symbol to avoid possible injury or death.

䕺Always wear protective goggles while using the machine.

The rivets may jump out by accident and cause injuries.

⚠ᵵᵟᵰᵬᵧᵬᵥ

䕺These Important Safety Instructions are divided into and .

The di"erences between these two levels are described below.

⚠ᵵᵟᵰᵬᵧᵬᵥ ⚠ᵡᵟᵳᵲᵧᵭᵬ

: Indicates a potentially hazardous situation which, if ignored, may result in death

or serious injury to the operator.

: Indicates a potentially hazardous situation which, if ignored, may result in moderate

injury to the operator or physical damage.

Moreover, failure to follow the instructions marked with the symbol or cautions without a

symbol which appear in the text of this manual may also have serious results in some

cases. Always be sure to observe the instructions given in the lmportant Safety Instructions.

⚠ᵡᵟᵳᵲᵧᵭᵬ

⚠ᵡᵟᵳᵲᵧᵭᵬ ⚠ᵡᵟᵳᵲᵧᵭᵬ

⚠ᵵᵟᵰᵬᵧᵬᵥ