Rev. A 11-2020

2

INDEX

1. INTRODUCTION................................................................................................................................................................................... 4

1.1 Preliminary information.................................................................................................................................................... 4

1.2 Aim and content of the manual ....................................................................................................................................... 4

1.3 How to store this manual ................................................................................................................................................. 4

1.4 Manual updates ............................................................................................................................................................... 4

1.5 How to use this manual ...................................................................................................................................................4

1.6 Potential risks .................................................................................................................................................................. 5

1.7 General description of symbols used............................................................................................................................... 6

1.8 Safety symbols used........................................................................................................................................................ 7

1.9 Limitations and prohibited use......................................................................................................................................... 7

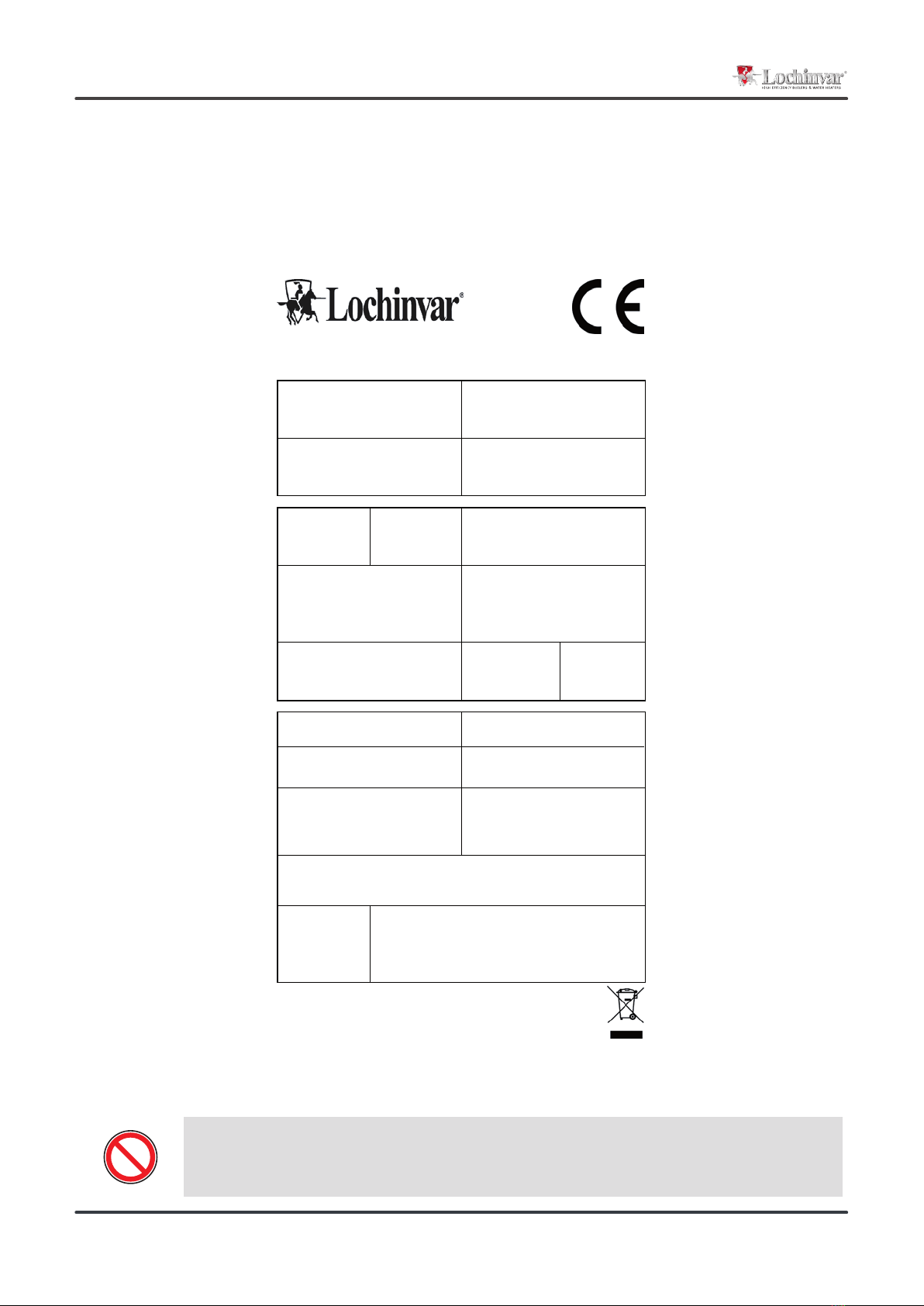

1.10 Unit identication .......................................................................................................................................................... 8

2. SAFETY .............................................................................................................................................................................................. 9

2.1 Warning re potentially hazardous toxic substances ........................................................................................................ 9

2.2 Refrigerant handling ....................................................................................................................................................... 9

2.3 Prevention of inhalation of high vapor concentrations................................................................................................... 10

2.4 Procedures in the event of accidental release of refrigerant ......................................................................................... 10

2.5 Main Toxicological information on the type of refrigerant used...................................................................................... 10

2.6 First aid measures ......................................................................................................................................................... 10

3. TECHNICAL CHARACTERISTICS .................................................................................................................................................... 11

3.1 Unit description.............................................................................................................................................................. 11

3.2 Versions ......................................................................................................................................................................... 12

3.3 Accessories description ................................................................................................................................................. 13

3.4 What is the E.V.I. technology (enhanced vapour injection) ........................................................................................... 14

3.5 Technical data................................................................................................................................................................ 15

3.6 Operation limits.............................................................................................................................................................. 16

3.7 Domestic hot water production ..................................................................................................................................... 17

3.8 Compressor capacity steps ........................................................................................................................................... 18

3.9 Correction tables............................................................................................................................................................ 18

3.10 Sound data .................................................................................................................................................................. 19

4. INSTALLATION................................................................................................................................................................................... 20

4.1 General safety guidelines and and use of symbols ....................................................................................................... 20

4.2 Workers’ health and safety ........................................................................................................................................... 20

4.3 Personal protective equipment ..................................................................................................................................... 20

4.4 Inspection ...................................................................................................................................................................... 21

4.5 Storage .......................................................................................................................................................................... 21

4.6 Unpacking...................................................................................................................................................................... 21

4.7 Lifting and handling........................................................................................................................................................ 22

4.8 Location and minimum technical clearances................................................................................................................. 22

4.9 Installation of rubber vibration dampers (KAVG)........................................................................................................... 24

4.10 Serial interface card RS485 (INSE)............................................................................................................................. 24

4.11 Installation of condensate drip tray (BRCA)................................................................................................................. 25

4.12 Hydraulic connections.................................................................................................................................................. 26

4.13 Chemical characteristics of the water.......................................................................................................................... 26

4.14 Hydraulic components ................................................................................................................................................. 27

4.15 User circuit minimum water content............................................................................................................................. 28

4.16 Domestic hot water (dhw) minimum water content...................................................................................................... 28

4.17 Filling the hydraulic circuit............................................................................................................................................ 28

4.18 Emptying the installation.............................................................................................................................................. 28

4.19 Typical installations ..................................................................................................................................................... 29

4.20 Wiring connections: Preliminary safety information ..................................................................................................... 30

4.21 Electric data................................................................................................................................................................. 31

4.22 Electric connections..................................................................................................................................................... 32

4.23 Positioning of the user circuit water inlet sensor (BTI)................................................................................................. 35

4.24 Refrigerant circuit layout.............................................................................................................................................. 36