Doc. Ref.No: Q875-0143/ENG Issue 2 Met 30+ Operating Manual 12/01/10

3. INTRODUCTION

This is the operating manual for the MET 30+ 1f and 3f range of metal detectors

including horizontal, pharmaceutical, waferthin, vertical-fall and pipeline, with VFD or

Touch Screen displays.

The MET 30+ detector uses the latest developments in digital signal processing

ensuring complete product integrity. The detector is able to store up to 100 sets of

automatic product set up values in memory.

The MET 30+ detector is capable of detecting and rejecting ferrous, non-ferrous and

non-magnetic stainless steel.

A penetrating electromagnetic field is generated within the detector head, and any

metallic contaminant within the detector specification will distort the electromagnetic

field and be detected no matter how deeply embedded in the product.

On detection a reject relay is activated, this relay is used to switch the automatic

reject device, which rejects the contaminated product.

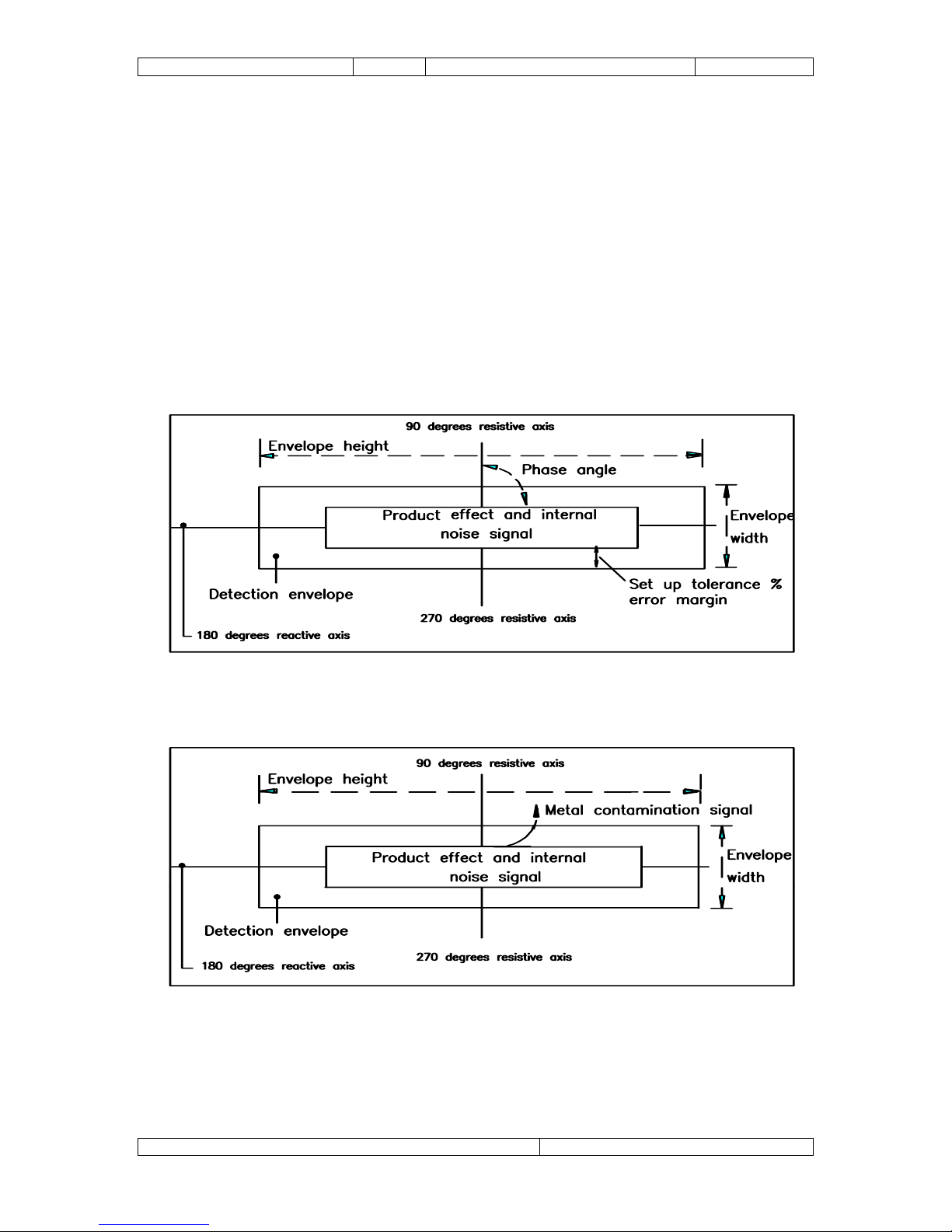

3.1 Detection Sensitivity

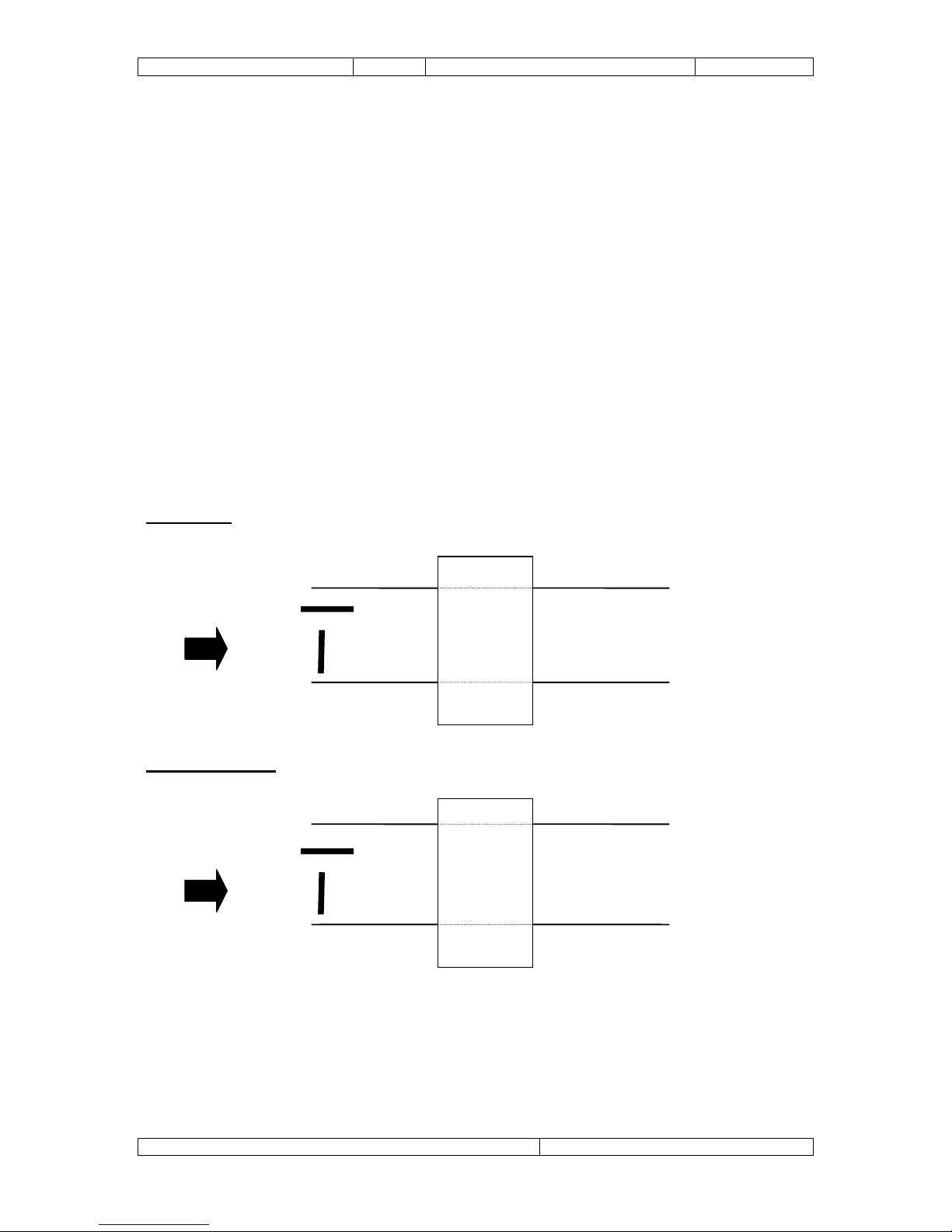

The sensitivity of a metal detector is governed mainly by the size of the aperture

through which the product is passed and is particularly dependent upon the minimum

dimension of that aperture. Therefore, in order to obtain a high sensitivity on a given

product, the aperture size should be kept as small as convenient while allowing

sufficient clearance around the product to prevent blockages.

To overcome discrepancies due to the shape of a metal sample, sensitivities are

always quoted in terms of diameters of spherical samples. This is referred to as

‘Spherical Sensitivity’.

File Name: Q875-0143 ENG Iss2 Met30+ Operating.doc Page 6 of 58