3

1INSTALLATION, USE AND SAFETY INFORMATION

READ THESE INSTRUCTIONS BEFORE WORKING WITH THE DEVICE

General warnings

Turnstiles.us cannot be held responsible for any damage resulting

from procedures which are not expressly indicated in this manual, or

from any lack of attention, either partial or total, of the procedures

described therein.

Read this manual carefully before installing, operating or carrying out

maintenance on the device. Keep the manual in a safe place for future

reference, and in perfect condition.

Follow the instructions contained in this manual for all operations

relating to installation, use and maintenance of the device.

All personnel operating with or performing operations on the device

must have an adequate preparation and shall know the procedures

described in this manual.

Observe current regulations regarding electrical and personal safety for

both the operator and the installer when installing the device.

Any modification to the configuration setup by Turnstiles.us is

forbidden and voids all warranties and certifications.

This manual must accompany the device described therein in the case

of change of ownership, and until the device is broken up.

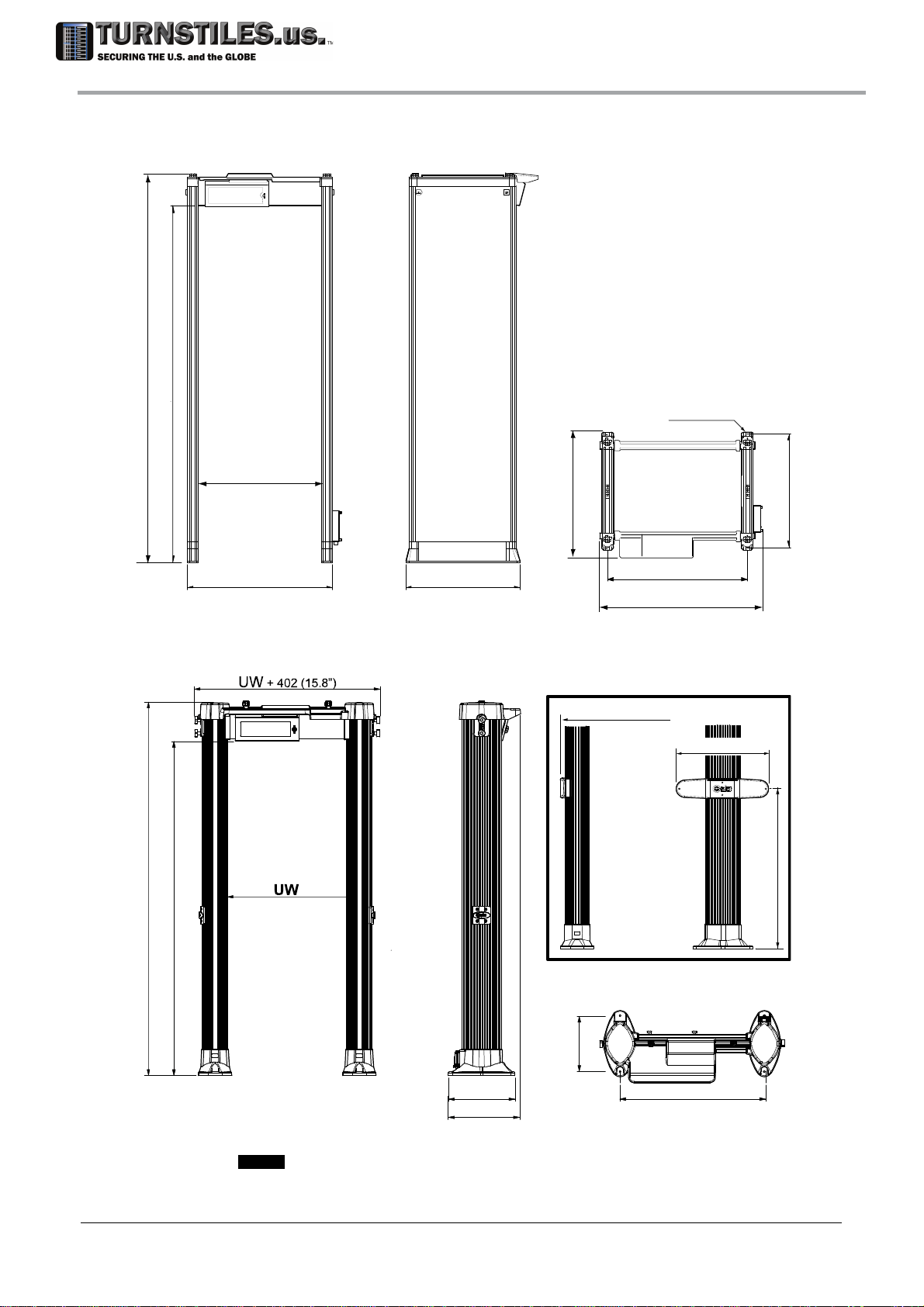

Due to its inherent natural construction the archway may be subjected

to slight deformation. A maximum 8 mm overall curvature of the

antenna still ensures unchanged performances.

Correct Use of the Device

A Metal Detector is a unit that reacts to the metal masses present on

people in transit.

As part of the normal screening process, people are required to walk

through the detector archway. A complete analysis requires a complete

passage through the archway.

Forbidden use of the Device

Any use different from that described in this manual is forbidden.

Operating limits

Refer to the ‘Specifications’ section.

Installation warnings

Observe current regulations regarding electrical and personal safety for

both the operator and the installer when installing the device.

Choose the installation site carefully. Avoid placing the device in

locations where it may be directly exposed to sunlight, in unventilated

areas or in places that are close to sources of heat. In addition, avoid

places that are subject to vibrations, dust, humidity, rain and

excessively high or low temperatures.

Installation must be carried out by qualified personnel. Given the

dimensions of the device, it is requested that the installation site be

kept clear while work is carried out to facilitate setting it up and to avoid

any harm to third parties.

Position the device as far away as possible from sources of

electromagnetic interference such as transformers or motors.

When installation is completed, the detector must be anchored to the

ground in a stable manner and not subject to vibrations (use expansion

screws inserted through the anchoring holes in the base of the panels).

All connecting cables between the gate and the power supply or other

external devices must be properly fixed and protected so as to achieve

the best performance from the detector and avoid accidental injury to

people who might trip over them.

Handle the device with care and without excessive force during

installation, use and maintenance.

Before powering up the device, check that the mains power supply

voltage corresponds to the voltage shown on the device's electrical

specifications plate. Verification that the power supply conforms to the

specified values plate and to the regulations in force is the total

responsibility of the customer.

The device should be connected to the mains voltage only after all the

connections required for full installation have been carried out.

The device must be connected to a power supply circuit fitted with a

switch or other device which allows the power to be cut off.

If the device is to be powered via an external autotransformer to

regulate the voltage, ensure that the common terminal of the

autotransformer is connected to the neutral of the power-supply circuit.

The power-supply plug must only be inserted into a socket fitted with

an earth/ground connection.

Any break in the safety conductor, either inside or outside the device,

or disconnection of the earth/ground safety terminal, will render the

device dangerous. Intentional cutting or disconnection is strictly

forbidden.

Whenever there is any suggestion that the level of protection has been

reduced, the device should be taken out of service and secured against

any possibility of unintentional use, and authorised service technicians

should be called.

The level of protection is considered to have been reduced when:

- the device shows visible signs of deterioration;

- the device does not operate correctly;

- the device has been stored for a long period in sub-optimal

conditions;

- the device has suffered mechanical or electrical stress (shocks,

bumps, etc..);

- the device has suffered severe stress during transport;

- the inside of the device has come into contact with liquids

Always remove the plug by hand when disconnecting the power supply

cable, never by pulling on the cable.

If the power-supply adapter is not waterproof: place it in a ventilated

position where it is protected from water (rain, condensation, liquid

detergents)! There is a risk of electric shocks for people and damage to

the equipment.

This device contains electrical and electronic components, and may

therefore be susceptible to fire. Do not install in explosive atmosphere

or in contact with inflammable material. Do not use water or foam in the

case of fire when the device is powered up.

To avoid damage due to lightning, fit the power supply line with

appropriate surge suppressors.

Do not use in an explosive atmosphere. Avoid contact with inflammable

or explosive material!

Medical Safety Information

The Metal Detectors comply with regulatory requirements for human

exposure to electromagnetic fields. THe manufacturer submits its devices

to testing by bodies qualified to check compliance with the emission limits

of the main standards currently in force (documentation available on

request). General information on use: the electromagnetic field emitted by

devices is extremely weak, with amplitude comparable with that of the

earth. However, the manufacturer cannot exclude that this device may

affect personal medical electronic devices, depending on their functionality

or their restrictions on use. Any recommendation or directive issued by

medical personnel or medical equipment manufacturers relating to

electromagnetic fields must therefore be implemented. If for any reason a

person about to pass through the detector shows fear or refuses to

undergo the inspection, it is recommended that the inspection be carried

out using an alternative method.

For further information on standard procedures to be followed for

inspection of people with implanted medical devices using a metal

detector, please consult the ASTM F2401-04 standard ‘Standard Practice

for Security Checkpoint Metal Detector Screening of Persons with Medical

Devices’ or other relevant directives.

Turnstiles.us is not responsible for direct or indirect harm to people or

things due to incorrect use of the Metal Detector.

Use warnings

The final user is responsible for selecting the appropriate security

level/sensitivity for their application. After this selection has been made,

and programming has been adjusted accordingly, it is also the final

user's responsibility to verify calibration using the test object(s)

appropriate to the level of security selected. Additionally, this test

should be carried out periodically (at least daily) to insure no changes

have occurred in the equipment. Reference Standards on this

argument include documents ASTM C 1270-97 and ASTM C 1309-97.

The execution of the test and its result shall be recorded. In case of a

negative result, the equipment should not be used.

The final user is responsible for determining and implementing the

appropriate inspection procedures and for the training of personnel

involved in carrying them out.

The information contained in this manual is provided only as a technical

reference for use and maintenance, and does not contain operational

procedures. For further information on standard procedures to be

followed for inspection of people using a metal detector, please consult

the guidelines entitled ‘The Appropriate and Effective Use of Security

Technologies in U.S. Schools’ by the National Institute of Justice or

other relevant directives.

Handle the device with care and without excessive force during use.

303-670-1099