© Allegion 2017

47259489 Rev 12/17-a

Customer Service

For details regarding the limited warranty:

1-877-671-7011 www.allegion.com/us

The EMS-100 is designed for use on request-to-exit applications with maglocks and electric strikes. This sensor is not an automatic door

activation sensor. It is a request to exit sensor used to release a lock.The unit is a passive infrared detector that uses digital signature

analysis for activation. The EMS-100 is not recommended for activation on pedestrian automatic doors because the passive infrared

technology recognizes temperature changes (i.e. body temperature) for detection. As such, the EMS-100 will not recognize motion

associated with inanimate objects such as hospital beds, gurneys, shopping carts, etc.

The key advantages of the EMS-100 are fast detection, adjustable sensing fields, and no false detection from inanimate objects.

EMS-100 Series

Exit motion sensor Instruction

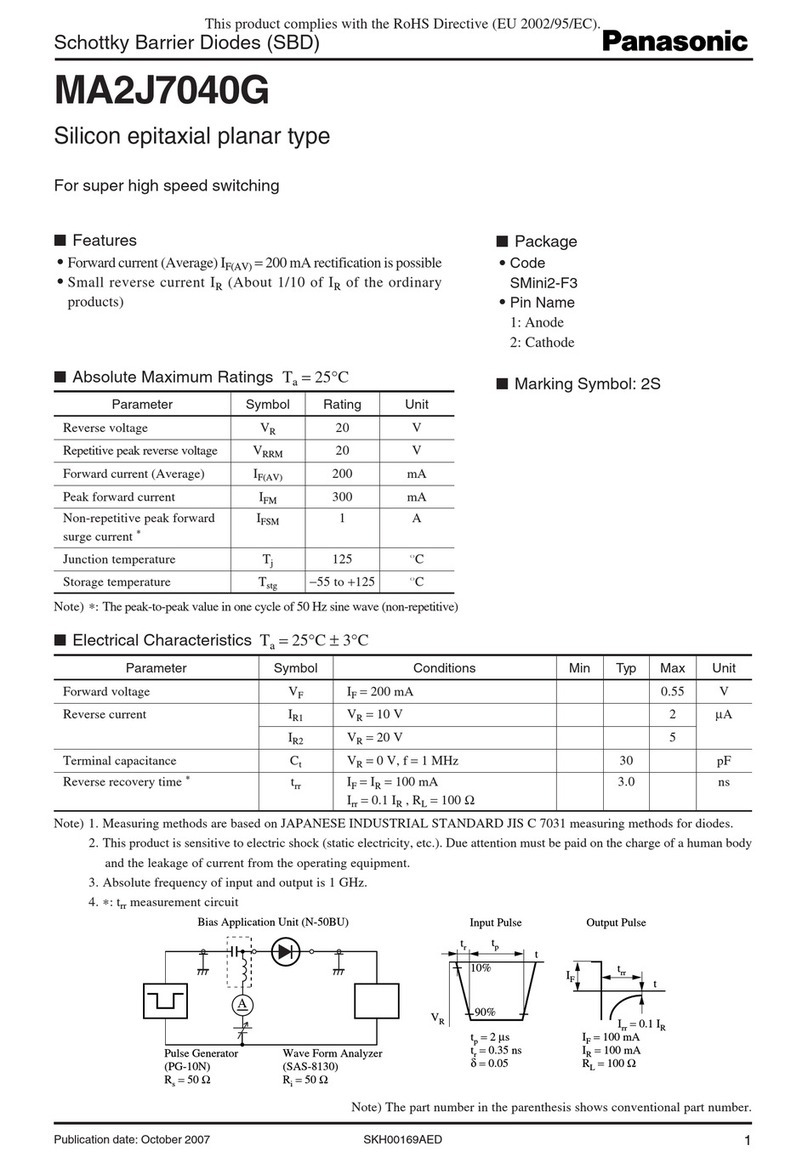

Technical Specifications

Product Description

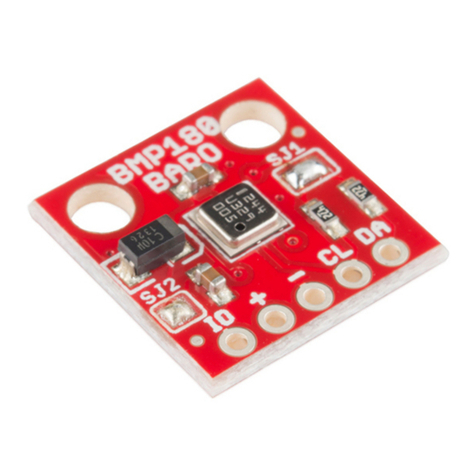

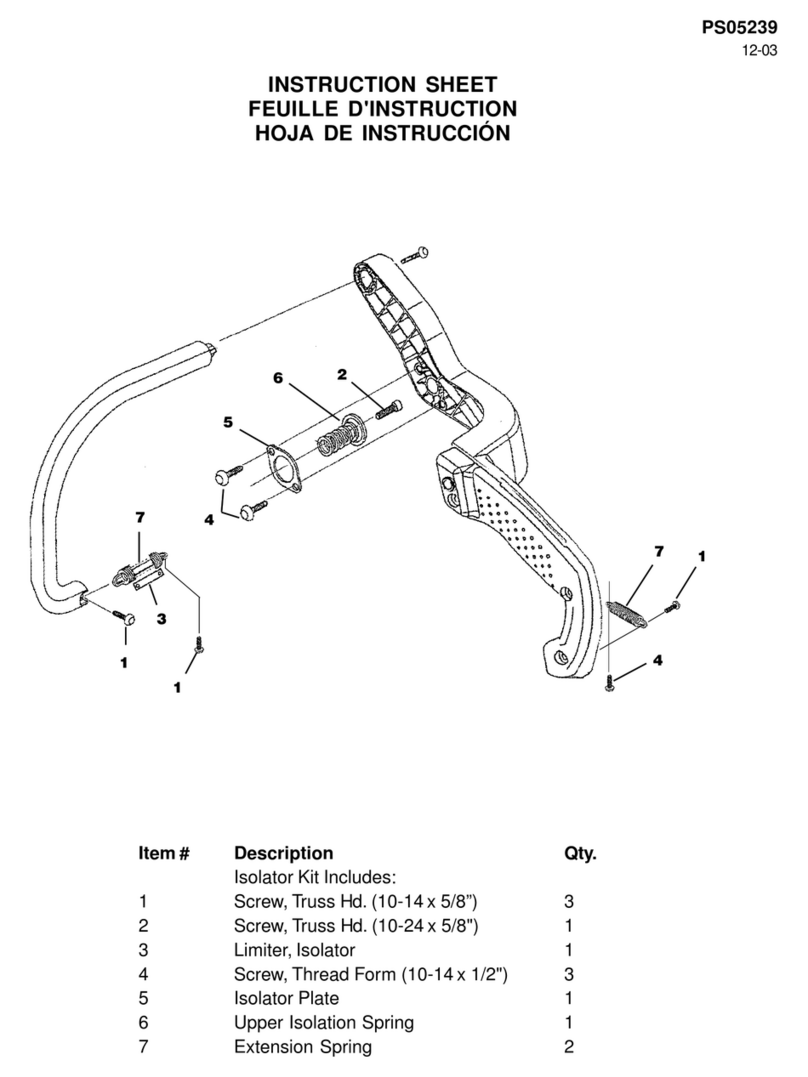

Component ID

Description Specification

Technology Passive infrared with microprocessor

Mounting Height - Variable 10’-0” max. (Recommended 6’-6” to 8’-0” )

Mounting Angles 0 to 180°

Power Supply 12-24 VAC –10/+10% (50/60Hz)

12-24 VDC –10/+30%

Current Consumption <10 mA (20mA if the relay output is activated)

Contact Rating (Output Relay) 1 A/ 75 VDC or 50 VAC Potential free contact NO/NC

Optical Characteristics Passive infrared with four elements

15 Fresnel lenses with full independent masking possibilities

Warm-up Time 10 seconds

Response Time Max 200 microseconds

Relay Hold Time 0.5 or 2 seconds

Operating Temperature -22°F to +140°F (-30°C to +55°C)

Immunity Immune to electrical and radio frequency interference

Cable 9 feet of four-conductor cable with 5-pin connector

Weight 1.4 oz. (40g)

Dimensions:

Sensor 4”L (100 mm.) x 1”H (25 mm.) x 1.8”W (45 mm.)

Housing Color Black

OPTIONAL ACCESSORIES:

Ceiling Adapter

Surface Adapter

SENSOR AND