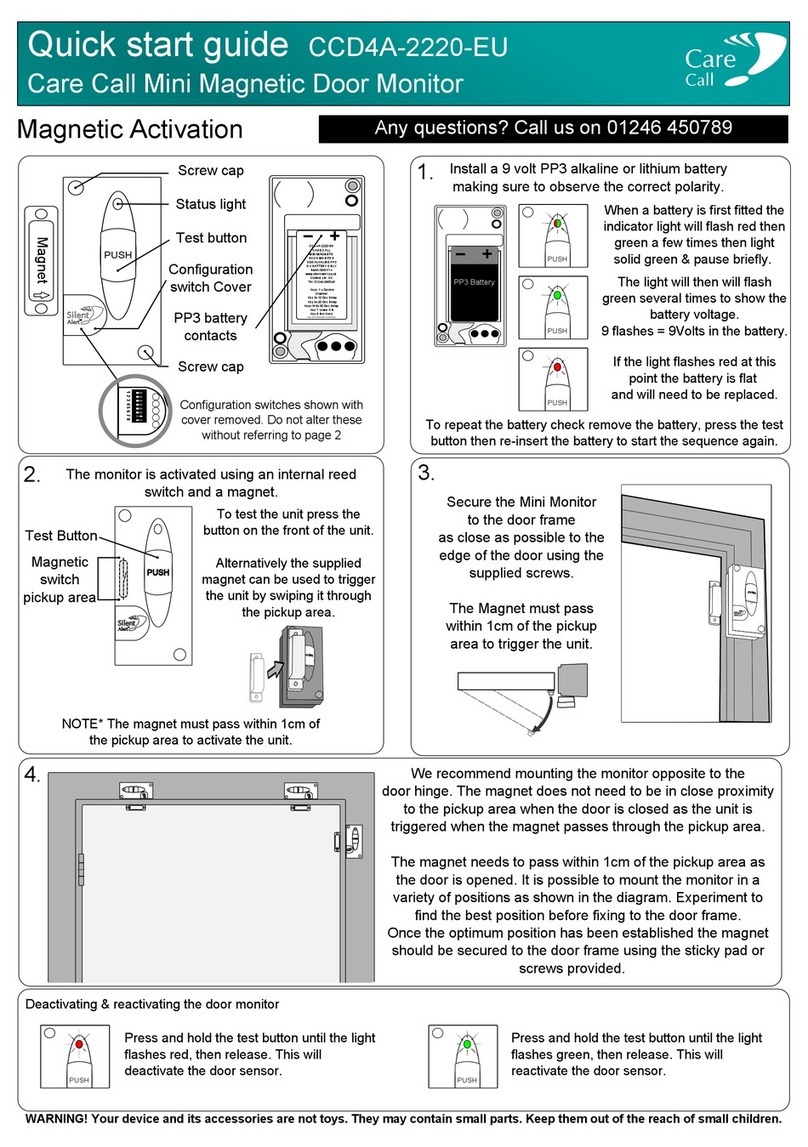

technotrans termotek P70100-24495 User guide

Instruction Manual

ORIGINAL INSTRUCTION MANUAL

Cooler

P70100-24495

90000899992-00 - EN

2019-07-02

2

Copyright clause

We reserve the right to implement technical changes which may result

in deviations from the illustrations and information contained in this

manual.

The translation, disclosure to third parties as well as any reproduction

and distribution are prohibited without our prior consent.

The main components, devices, arrangements, software as well as the

control and instrumentation equipment on all of our products are

protected both at home and abroad by patent applications, patents,

utility models or copyrights.

Copyright by

termotek GmbH

Im Rollfeld 6

D-76532 Baden-Baden

Federal Republic of Germany

termotek GmbH

www.gds.eu

3

1 Contact Addresses.................................................................................................................................5

1.1 Manufacturer's address ..................................................................................................................... 5

1.2 Service addresses ............................................................................................................................. 5

1.3 Making contact................................................................................................................................... 7

2 About this manual ..................................................................................................................................8

2.1 Use and storage ................................................................................................................................ 8

2.2 Target audience................................................................................................................................. 9

2.3 Explanation of the various notes ..................................................................................................... 10

2.4 Seal of quality .................................................................................................................................. 11

3 Liability and warranty ..........................................................................................................................12

3.1 General information ......................................................................................................................... 12

3.2 Terms of warranty............................................................................................................................ 13

3.3 Information on IT Safety .................................................................................................................. 14

4 Safety.....................................................................................................................................................15

4.1 General information ......................................................................................................................... 15

4.2 Intended use .................................................................................................................................... 16

4.3 Safety of personnel.......................................................................................................................... 16

4.4 Transport and installation/start-up ................................................................................................... 18

4.5 Operation ......................................................................................................................................... 19

4.6 Maintenance .................................................................................................................................... 19

4.7 Operating faults ............................................................................................................................... 19

4.8 Residual risks .................................................................................................................................. 20

4.9 Use of chemicals ............................................................................................................................. 20

4.10 Use of cleaning agents .................................................................................................................... 21

4.11 Safety labels .................................................................................................................................... 22

5 Description / Overview.........................................................................................................................23

5.1 General information ......................................................................................................................... 23

5.2 Safety devices ................................................................................................................................. 24

5.3 Factory protective measures ........................................................................................................... 24

5.4 Deactivation ..................................................................................................................................... 24

5.5 Foreseeable misuse ........................................................................................................................ 25

6 System Layout ......................................................................................................................................26

6.1 Overview.......................................................................................................................................... 26

6.2 Information concerning the refrigerant............................................................................................. 28

6.3 Refrigeration unit ............................................................................................................................. 29

6.3.1 General information ..................................................................................................................... 29

6.3.2 Obligation to maintain records..................................................................................................... 30

7 Transport...............................................................................................................................................31

7.1 Notes................................................................................................................................................ 31

7.2 Transport and packaging material ................................................................................................... 31

7.3 Transport to the installation location................................................................................................ 32

7.4 Installation site ................................................................................................................................. 33

4

8 Setting Up..............................................................................................................................................34

8.1 Notes................................................................................................................................................ 34

8.2 Installation........................................................................................................................................ 35

8.3 Medium connections........................................................................................................................ 36

8.4 Electrical connection........................................................................................................................ 38

8.5 Filling................................................................................................................................................ 39

8.6 Final steps after start-up.................................................................................................................. 41

9 Operation...............................................................................................................................................42

9.1 Notes................................................................................................................................................ 42

9.2 Switching the unit on or off .............................................................................................................. 43

9.3 Adjustments ..................................................................................................................................... 43

9.4 Refilling ............................................................................................................................................ 43

10 Maintenance..........................................................................................................................................44

10.1 Notes................................................................................................................................................ 44

10.2 Maintenance plan ............................................................................................................................ 46

10.3 Draining off the medium / Refilling the cooler with medium ............................................................ 48

10.4 Filter replacement ............................................................................................................................ 49

10.5 Refrigeration unit ............................................................................................................................. 50

10.5.1 General information ................................................................................................................. 50

10.5.2 Refrigerant sight glass ............................................................................................................. 51

10.6 Restart ............................................................................................................................................. 51

11 Troubleshooting ...................................................................................................................................52

11.1 Notes................................................................................................................................................ 52

11.2 General malfunctions....................................................................................................................... 53

11.3 Electrical connection........................................................................................................................ 54

11.4 Refrigeration unit ............................................................................................................................. 54

11.4.1 Refrigerant sight glass ............................................................................................................. 55

11.5 Unit-specific ..................................................................................................................................... 56

11.6 Restart ............................................................................................................................................. 56

12 Disconnecting the device ....................................................................................................................57

12.1 Notes................................................................................................................................................ 57

12.2 Dismantling ...................................................................................................................................... 58

12.3 Transport and storage ..................................................................................................................... 59

12.4 Recycling ......................................................................................................................................... 60

13 Technical data and further information .............................................................................................61

14 Index ......................................................................................................................................................62

Contact Addresses

5

1 Contact Addresses

1.1 Manufacturer's address

termotek GmbH

Im Rollfeld 6

D-76532 Baden-Baden

Phone +49 (0) 72 21 9711-0

Fax +49 (0) 72 21 9711-111

Germany

1.2 Service addresses

Europe

termotek GmbH

Im Rollfeld 6

D-76532 Baden-Baden

Phone +49 (0) 72 21 9711-0

Fax +49 (0) 72 21 9711-111

Email: service@termotek.de

Germany

technotrans SE

Robert-Linnemann-Straße 17

48336 Sassenberg

Phone: +49 (0) 25 83-301-2000

Fax: +49 (0) 25 83-301-2547

Email: custom[email protected]

Germany

technotrans graphics ltd.

Axis One, Brunel Way

Severalls Business Park

Colchester, Essex CO4 9QX

Phone: +44 (0) 1206-2242-00

Fax: +44 (0) 1206-2242-01

Email: service-uk@technotrans.co.uk

England

technotrans france sarl

ZAET “Les Haies“

Rue Albert Einstein

60740 Saint-Maximin cedex

Phone: +33 (0) 3 44-24 2128

Fax: +33 (0) 3 44-24 85 26

Email: service-france@technotrans.fr

France

technotrans France SARL

Surcusal en ESPAÑA

Paseo de Recoletos, 7 y 9, 5a

28004 Madrid

Phone: +34-91 679 2119

Email: service-spa[email protected]

Spain

technotrans italia s.r.l.

Via Spallanzani, 18

20025 Legnano (Mi)

Phone: +39 (0) 3 31-45 56 09

Fax: +39 (0) 3 31-45 50 65

Email: service-ital[email protected]t

Italy

America

technotrans america inc.

1441 E. Business Center Drive

Mt. Prospect, Illinois 60056

Phone: +1 (847) 227-9200

Fax: +1 (847) 227-9400

Email: service-usa@technotrans.com

USA

technotrans américa latina

Alameda Mercúrio, no. 318

American Park Empresarial

13347-662 Indaiatuba - SP

Phone: +55 (19) 3936-7900

Fax: +55 (19) 3935-1304

Email: servico@technotrans.com.br

Brasil

Contact Addresses

6

Asia

technotrans Asia-Pacific limited, Japan branch

322 Sannomiya Venture Building

4-1-23 Hamabe-Dori, Chuo-Ku

Kobe 651-0083

Phone: +81 3 5484 3180

Fax: +81 3 5484 3181

Email: service-japan@technotrans.com

Kobe, Japan

technotrans technologies pte.ltd

66 Kallang Pudding Road #04-03

Hor Kew Business Centre

Singapore 329324

Phone: +65 6508 6800

Fax: +65 6844 1566

Email: service-singapore@technotrans.com

Singapore

technotrans india pvt ltd.

#24, Eden Plaza Second Floor

Mount Poonamallee High Road

Nandambakkam, Chennai 600 089

Tamil Nadu

Phone: +91 (0) 44 4351 9349

Email: service-india@technotrans.com

Chennai, India

technotrans group (taicang) co., ltd

No. 8 North Loujiang Road

Taicang 215400

P.R.China

Phone +86 (0) 512 5367 8100

Fax +86 (0) 512 5367 8199

China

Australia

technotrans technologies pte ltd

Unit 7 / 111 Lewis Road

Wantirna

Victoria 3152

Phone: +61 3 9887 5049

Fax: +61 3 9801 1945

Email: service-austra[email protected]

Australia

Contact Addresses

7

1.3 Making contact

Please keep the following details ready (see the type plate of the unit) when

contacting us (e.g. for spare part orders, warranty claims, etc.):

• Product name

• Serial no.

NOTE

If necessary, enter the information, which is stated on the type plate of the unit,

into the table.

Name of the unit:

(Product Name) ……………………………………

Serial number:

(Serial No.) ……………………………………

Part number:

(Part No.) ……………………………………

Year of manufacture:

(Year of Manufacture) ……………………………………

About this manual

8

2 About this manual

2.1 Use and storage

NOTE

Prior to performing any work on the unit/system, read the instruction manual.

The following points must be noted:

• The instruction manual is an integral part of the unit/system and must be

available to the operating personnel at the unit/system at all times.

• The instruction manual is indispensable for the safe start-up, operation and

maintenance of the unit/system in line with its intended purpose.

• The instruction manual applies solely to the product that is stated on the

cover sheet.

• We reserve the right to change the instruction manual due to further

technical developments.

• This instruction manual is part of the scope of supply.

• The instruction manual shall apply from the transport phase up to the final

disposal and must be absolutely observed.

• Keep the instruction manual in a place where it is readily accessible at all

times. It must be complete, remain with the machine and must be available

to all authorised persons.

• Maintain the instruction manual in a clearly legible state at all times.

• Hand over the instruction manual along with the device if it is resold.

• The unit/system may present unavoidable residual risks to persons and

property. This is why the instruction manual must be read, understood and

strictly complied with for all types of tasks by the personnel prior to

commencing any work. In addition, any person who works on or with the

unit/system in any way must be instructed and familiar with the potential

hazards.

• This instruction manual is solely intended for trained and authorised

personnel.

• It is the operator's responsibility to ensure that the manual is read and

understood by all operating personnel before starting work.

• The illustrations in this manual are for providing a basic understanding and

may differ from the actual unit/system.

About this manual

9

2.2 Target audience

When working with the unit/system, the various tasks must be assigned to specific

groups of persons.

Depending on the location of use, the necessary qualification of the personnel may

be subject to varying statutory provisions. The operator must ensure compliance

with the relevant laws. Unless regulated by law, the following list is used to define

the permissible personnel and their minimum qualification.

The following points must be noted:

• Any work on the unit/system must be performed by qualified and instructed

personnel.

• The personnel must have knowledge of the relevant standards, provisions,

accident prevention regulations and operating conditions.

• The personnel must be instructed and trained for the tasks that need to be

performed.

• The personnel must be able to identify and avoid any potential hazards.

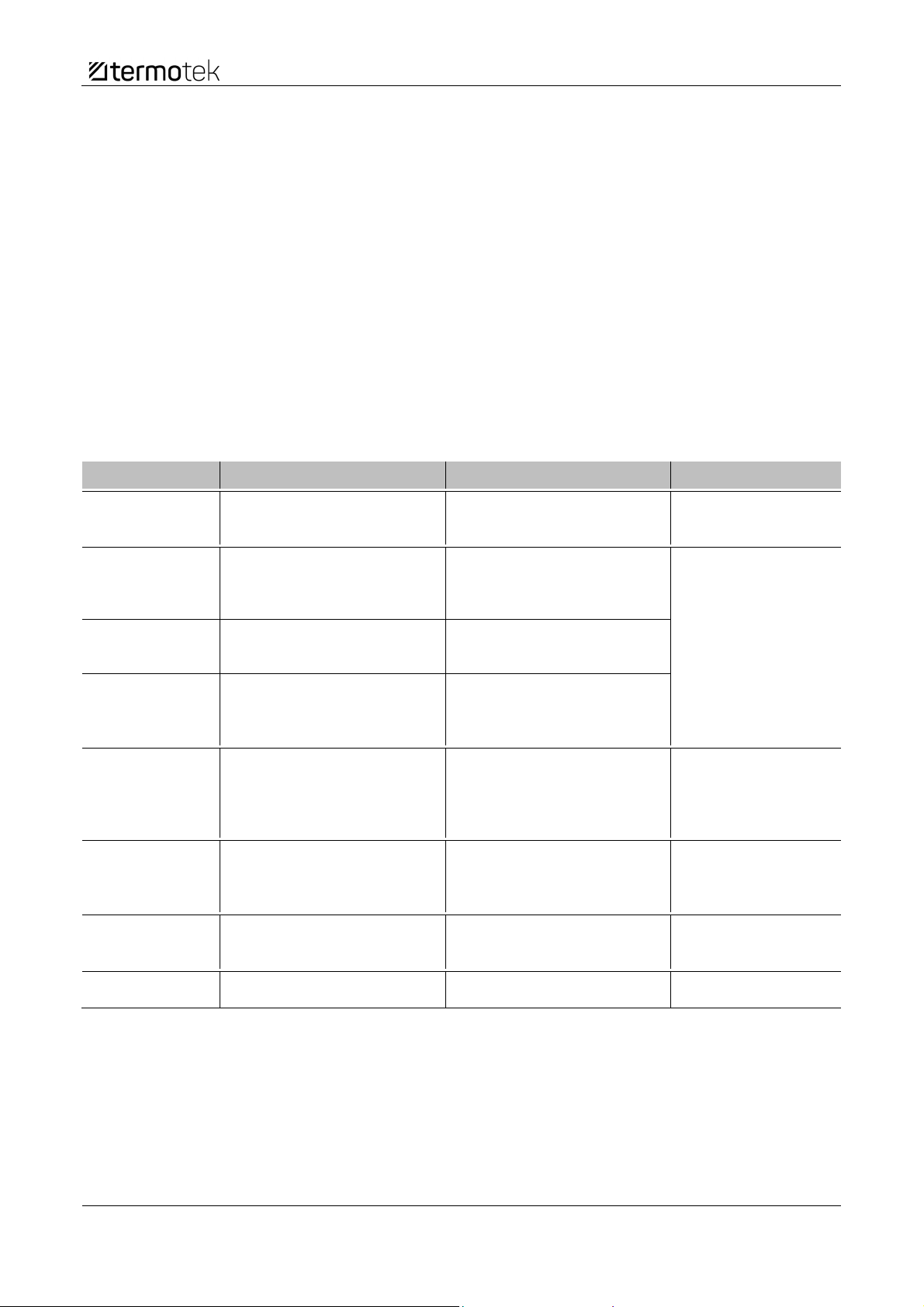

Person Task Qualification Lifcycle phase

Qualified

personnel for

transporting loads

Lifting/lowering and transport

of the system

Proven experience in the

handling of suspended loads

and in the securing of loads

Transport, installation,

disassembly and

removal

Qualified

personnel

(mechanics)

Mechanical work during: start-

up, elimination of faults and

malfunctions, maintenance

and shut-down

Training as an industrial

mechanic or an equivalent

professional qualification

Start-up, maintenance,

elimination of faults

and malfunctions,

shut-down,

disassembly and

removal

Qualified

personnel (trained

electricians)

Electrical work Specialised electrical training

or an equivalent professional

qualification

Qualified

personnel

(refrigeration

specialists)

Work on the refrigeration unit Training as a refrigeration

specialist or an equivalent

professional qualification

Qualified

personnel

(machine

operators and

fitters)

Operation and set-up of the

system

Person who has been trained

and instructed by the operator

based on the instructions for

use

Start-up, operation,

maintenance,

elimination of faults

and malfunctions

Qualified

personnel

(disposal

specialists)

Proper disposal of the system Knowledge about the disposal

regulations applicable on site

Shut-down,

disassembly and

removal, disposal

Qualified

personnel (safety

specialists)

Implementation of the

applicable safety regulations

Knowledge about the safety

regulations applicable on site

All phases

Others (e.g.

visitors)

Site inspection Person under the supervision

of a safety specialist

-

About this manual

10

2.3 Explanation of the various notes

The warning notes are preceded by signal words indicating the severity of the

hazard.

Compliance with the warning notes is imperative in order to avoid accidents,

injuries and damage to property.

Explanation of warning notices used in this manual:

DANGER

Short description of danger

The signal word DANGER identifies an immediately threatening danger.

Any non-adherence will result in severe injuries or death.

WARNING

Short description of danger

The signal word WARNING identifies a potential danger.

Any non-adherence may result in severe injuries or death.

CAUTION

Short description of danger

The signal word CAUTION identifies a potential danger.

Non-compliance may result in minor to medium injuries.

NOTICE

Short description

The signal word NOTICE identifies a potential risk of damage to property.

Non-compliance may cause damage to the unit or system.

NOTE

The signal word NOTE identifies further information on the unit or about its use.

Note concerning the protection of the environment

The keyword Note concerning the protection of the environment indicates

information concerning the protection of the environment.

About this manual

11

2.4 Seal of quality

The seal of quality "gdsCert" of gds GmbH (service provider for technical

documentation) is a proof of quality for technical documentation.

With the "gdsCert" seal of quality, the manufacturer provides proof of the high

standard of the technical documentation and of the compliance with the relevant

standards and guidelines.

The seal of quality "ecoDoc" is used for the certification of instruction manuals

under ecological points of view. It is listed under the "green safety instruction".

With the "ecoDoc" seal of quality, the manufacturer indicates that the product

documentation includes notes concerning the potential ecological hazards

resulting from operating errors or other tasks that are performed with or on the

product. Companies thereby make a contribution to the protection of the

environment.

The seal of quality "ecoDoc" provides a proof of compliance with the relevant

standards and guidelines and/or of the ecological approach concerning the

contents of the documents.

Liability and warranty

12

3 Liability and warranty

3.1 General information

The unit/system has been manufactured in line with the state of the art as well as

the recognised safety regulations and standards. Still, its use may jeopardise the

health and safety of the user or third parties or cause damage to the unit/system or

other property.

Warranty and liability claims for injuries to persons/damage to property are

excluded if they are due to one or several of the following causes:

• Improper use of the unit/system not in line with its intended use

• Non-compliance with the instruction manual and its associated parts and

annexes

• Unauthorised structural or technical modifications of the unit/system

• Use of untrained personnel

• Use of the unit/system with defective or improperly installed safety devices

and guards

• Operating errors

• Failure to maintain the unit/system

• Non-elimination of faults/malfunctions

• Use of non-authorised spare parts

• Other misuse

• Catastrophic events caused by foreign objects or force majeure

The information in this instruction manual describes the characteristics of the

product without guaranteeing them.

No claims for the modification of components that have already been supplied may

be made on the basis of the information, illustrations and descriptions in this

instruction manual. The information, data and notes included in this instruction

manual were up to date at the time of printing.

Liability and warranty

13

3.2 Terms of warranty

The manufacturer cannot be held liable for damage resulting from improper use,

non-compliance with this manual, the employment of insufficiently qualified

personnel, or unauthorised modifications. In these cases the manufacturer’s

warranty is rendered void.

The correct operation of the unit will be impaired if incorrect spare parts are used!

The correct operation of the unit cannot be guaranteed if components are used

which have not been approved. Only use spare parts approved by the after-sales

service.

No warranty claim!

The use of media (e.g. washing agents, additives, cleaning agents, etc.) that are

not approved may result in damage to the unit or system. The warranty will be

rendered void. The same shall apply when different media are mixed.

Use only media that have been approved by the manufacturer.

NOTE

Removing type plates will make the warranty claim expire.

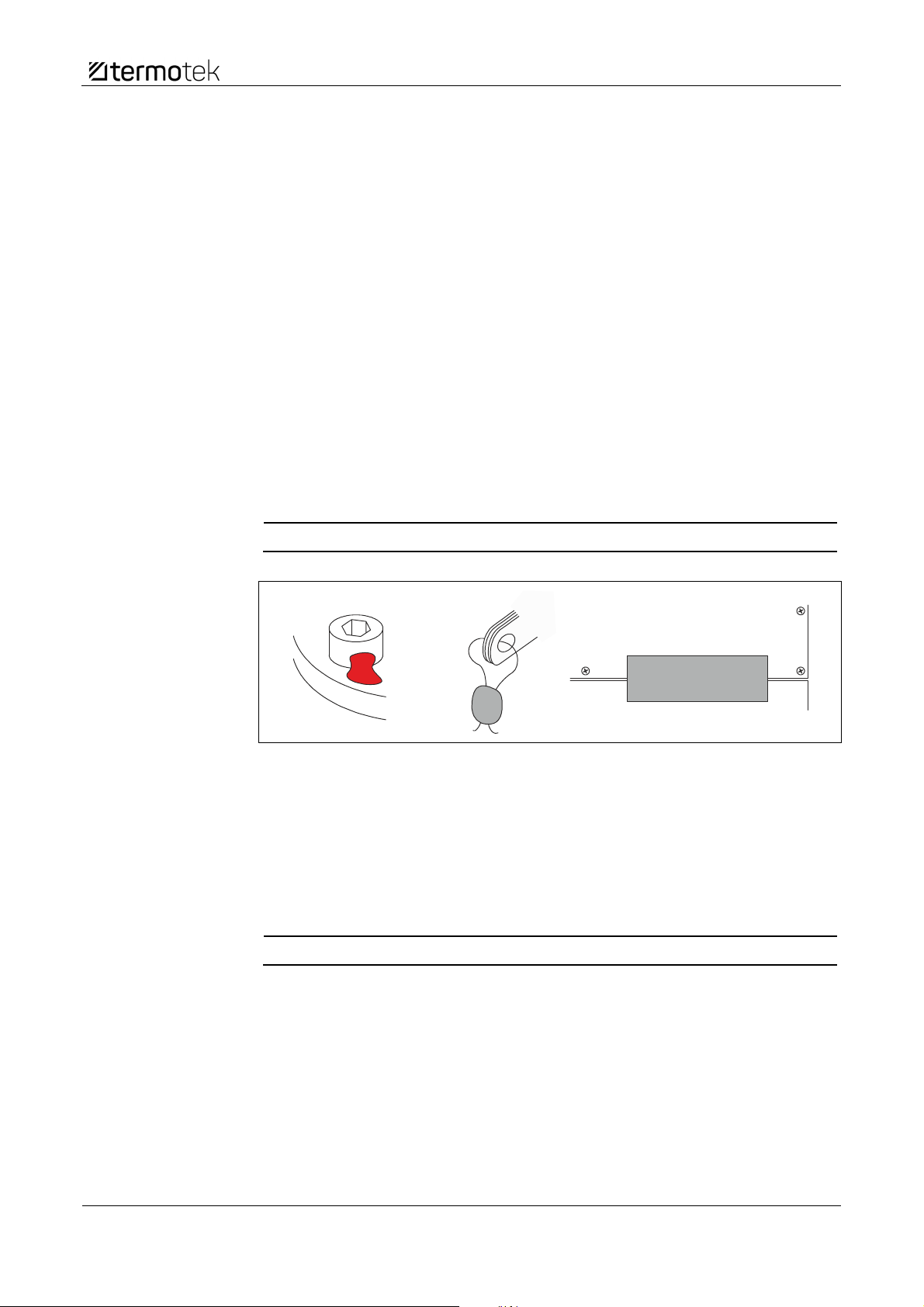

Fig. 1: Sealings

Sealings may exist at various different locations at the unit or plant:

1 Sealing wax (Application example)

2 Seals (Application example)

3 Seal stickers (Application example)

NOTE

The warranty will be rendered void if sealings are broken without authorisation.

10437-02

1

3

2

Liability and warranty

14

3.3 Information on IT Safety

Devices with a communication interface are designed to be connected to a

customer's network interface and to use these devices to transmit information and

data.

The operating company is solely responsible for providing and ensuring a safe

connection between the device and the network.

The operating company must undertake to provide and maintain appropriate

measures (such as installing firewalls, using authentication, data encryption,

installing anti-virus programs, etc.) to protect the device, the network, its systems

and the interface from any interference. The operating company must undertake to

protect the device from vulnerabilities, prevent unauthorised access, faults,

intrusion, loss, and/or theft of data or information.

technotrans SE and its subsidiaries shall not be held liable for any damage and/or

loss caused by such security breaches, unauthorised access, faults, intrusion or

loss and/or theft of data or information.

Safety

15

4 Safety

4.1 General information

NOTE

Every person who is ordered to work on the unit/system must have read and

understood these instructions and, in particular, the "Safety" chapter.

If necessary, in-house instruction should be provided, taking into account the

technical qualifications of the personnel concerned.

The "Safety" chapter provides an overview of all of the important safety aspects for

the optimum protection of the personnel and for the safe and trouble-free use of

the unit/system from the transport up to the operation and disposal.

The unit/system has been designed and manufactured in line with the current state

of the art and is in compliance with the recognised safety regulations and

standards.

The unit/system is safe to operate.

Non-compliance with the instructions and safety notes in this instruction manual

may lead to substantial hazards to persons and damage to the unit/system.

Only use specialised personnel who are familiar with the fundamental health and

safety rules and regulations and who have been briefed about the handling of the

unit/system.

Certain components have additional warning plates or labels to ensure safe

operation. Plates or labels must not be covered or removed.

Compliance with the safety instructions is mandatory. The observation of these

instructions is essential for ensuring safety.

The relevant accident prevention regulations as well as other generally recognised

regulations concerning workplace health and safety must be observed.

Safety

16

4.2 Intended use

The unit or the system is intended solely for the application outlined in the

“Description/Overview” section and only with the components supplied and

approved.

Using the unit for purposes other than those mentioned above is considered

contrary to the intended use. The manufacturer cannot be held liable for any

damage resulting from such use. The risk of such misuse lies entirely with the user.

The product-specific documentation can only refer to the intended use of the

unit/system on which the order is based.

The instructions cannot cover any specific situations arising from special local

conditions or special applications that the manufacturer was not aware of. In this

case, the operator must ensure the safe operation of the unit/system or shut the

unit/system down until appropriate measures for the safe operation have been

coordinated or implemented in consultation with the manufacturer or other

competent authorities.

4.3 Safety of personnel

Knowledge of, and compliance with, the present content is a prerequisite for the

protection of persons against danger and for the avoidance of errors and mistakes.

Tasks (e.g. maintenance and service tasks) should be performed only by suitably

qualified persons who are familiar with these tasks and who have been informed

concerning the potential danger.

Avoid any working practice that:

• puts the health and safety of the user or third parties at risk,

• is detrimental to the unit or system or other material assets,

• impairs the safety or functionality of the unit or system,

• does not comply with the safety instructions.

In addition:

• Always wear personal protective equipment when working on the

unit/system.

• Comply with the relevant accident prevention regulations.

• Comply with the occupational health regulations.

• Comply with the generally recognised safety rules.

Safety

17

There is an increased risk of injury if the safety devices and guards are disabled.

Never dismantle or disable any safety devices or guards.

• Check the safety devices and guards daily for correct operation.

• Report any faults and defects concerning the safety devices and guards to

the customer service without delay.

• Keep covers (e.g. panels, shields, housings) closed during operation.

• Perform repairs of the pipe systems and tanks only when the system is

depressurised.

• Observe the respective supplier's safety data sheets and disposal

instructions as well as all of the local safety regulations when using

chemicals.

• When handling process fluids (e.g. oils, greases and other chemical

substances), comply with the supplier's specifications and safety information

for the respective product.

• Wear personal protective equipment.

Failure to wear personal protective equipment may cause serious injuries or death.

• Wear the prescribed personal protective equipment, e.g. hearing protection,

eye protection, safety shoes, helmet, protective clothing, safety gloves, and

respiratory protective equipment.

• Long hair must be tied back. Do not wear any jewellery or loose-fitting

clothes. There is a risk of injury if these items get caught in or are pulled into

any moving parts of the machinery.

• Ensure that there are no unauthorised persons in the danger zone.

Any safety devices that have been removed for set-up, maintenance, or repair

purposes must be reinstalled and checked for correct operation immediately upon

the completion of the maintenance and repair work.

In the above case, particular attention must be paid to the general accident

prevention and safety regulations.

There is a risk of damage to property if the unit/system is operated improperly.

• Comply with the description of any add-on parts or ancillary equipment (if

included).

• See also the supplier documentation or the separate documentation

provided by the third-party suppliers.

Safety

18

4.4 Transport and installation/start-up

There is an increased risk of injury for persons who perform tasks for which they

are neither qualified nor trained.

Only persons who are familiar with the tasks, who have been informed about the

associated hazards have the necessary qualifications are authorised to transport

the unit.

• Never work or stand under suspended loads. There is a risk of fatal injuries

from falling loads.

• Transport tasks may only be performed by qualified and authorised persons

and in compliance with the safety instructions!

• The shipping company and the manufacturer must be informed immediately

in writing about any damage that is noticed after the delivery. The start-up of

the unit/system must be suspended, if necessary.

• Use only suitable lifting devices, transport equipment, load handling

attachments and lifting accessories and ensure that they are in a perfect

technical state and have a sufficient load-bearing capacity.

• Take the attachment points and centre of gravity of the load into

consideration.

• Do not add any additional attachment points to the units/systems by welding,

flame cutting or drilling. There is a risk of cracking due to the notch effect of

the weld seam or flame-cutting spot or bore.

• When transporting the unit, observe the instruction labels on the unit (if

provided).

• Transport the unit only when it is empty.

• If the unit/system needs to be replaced, fasten and secure it thoroughly on

the lifting devices.

• The banksman must be within the range of vision of the operator or have

voice contact with the operator.

• Block and mark the transport routes so that unauthorised persons cannot

reach the hazard area!

• Always secure the transport route with the aid of a third person!

NOTE

Comply with the general accident prevention and safety regulations.

Safety

19

4.5 Operation

• Operation is permissible only if all of the components are in a perfect

technical state and proper operational condition and if they are used in line

with the intended purpose.

• Avoid any operation that compromises the safety of the unit/system.

• The operator must ensure that unauthorised persons cannot work on the

machine.

• Prior to switching the unit/system on, the operator must ensure that no

persons are put at risk by starting the machine.

• During operation, the entire hazard area must be observed or closed off so

that no one can enter this area without being noticed.

• Do not leave the unit/system unattended during operation.

• Use the unit/system only if all of the guards and safety devices are present

and fully functional.

• The operator must ensure a clean and clearly arranged workplace at and

around the unit/system by issuing corresponding instructions and performing

checks.

• Observe the controls and indicators during operation.

4.6 Maintenance

The operator must ensure that the unit/system and its safety devices and guards

are kept in a functional state. The control devices as well as the safety devices and

guards must be checked in terms of their effectiveness.

Only specialised and trained personnel are authorised to perform maintenance,

repairs and overhauls.

If safety devices or guards need to be removed for maintenance, overhauls and

repairs, they must be reinstalled and checked for correct operation immediately

after the completion of the tasks.

4.7 Operating faults

Malfunctions of the unit/system may be caused by a fault that can be localised and

eliminated with the aid of the "Troubleshooting" section.

• Assign the associated tasks to the corresponding specialised personnel.

• If the fault cannot be eliminated, contact the service of the manufacturer.

NOTE

See the "Contacts" section.

Safety

20

4.8 Residual risks

Any unavoidable, design-based residual risks (if present) are mentioned and

described in this instruction manual in the corresponding sections.

4.9 Use of chemicals

Health hazard!

The use of chemicals can present a health hazard.

• When handling chemicals, always wear protective gloves, eyewear, and

clothing.

• Observe the safety data sheets.

Damage due to aggressive chemicals!

Aggressive chemicals can damage the components.

• Do not use any chemicals (e.g. for cleaning) that are aggressive to the

components.

• Observe the relevant material safety data sheets of the suppliers.

Note concerning the protection of the environment

The improper disposal of chemicals (e.g. additives) has a negative impact on the

environment.

• Chemicals must not be disposed of as household waste and it must be

ensured that they are not released into the sewage system or soil.

• Wear suitable protective equipment (gloves, eye protection) when

performing disposal tasks.

• Chemicals must be disposed of separately (e.g. as special waste if

applicable) and supplied separately to the recycling centres.

• Comply with the safety data sheets and also with the applicable national

and local rules and regulations.

Table of contents