3

WARNINGS

SAVE THESE INSTRUCTIONS

• The installation must conform with local codes

or, in absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, Storage

and Handling of Liqueed Petroleum Gases,

ANSI/NFPA 58; or Natural Gas and Propane

Installation Code, CSA B149.1; Propane

Storage and Handling, CSA B149.2.

• This appliance is not designed for use with

natural gas.

• Never operate this appliance on or under any

apartment or condominium balcony or deck.

• This appliance is for outdoor use only. Never

use this appliance in a building, garage or any

other enclosed area.

• Never install or use this appliance in or on a

boat or recreational vehicle.

• Maintain proper clearances from combustible

construction. The minimum clearance to the

sides and back of the appliance is 10 ft (3 m)

from any structure or combustible material. Do

not locate or use

the appliance

under overhead

combustible

construction.

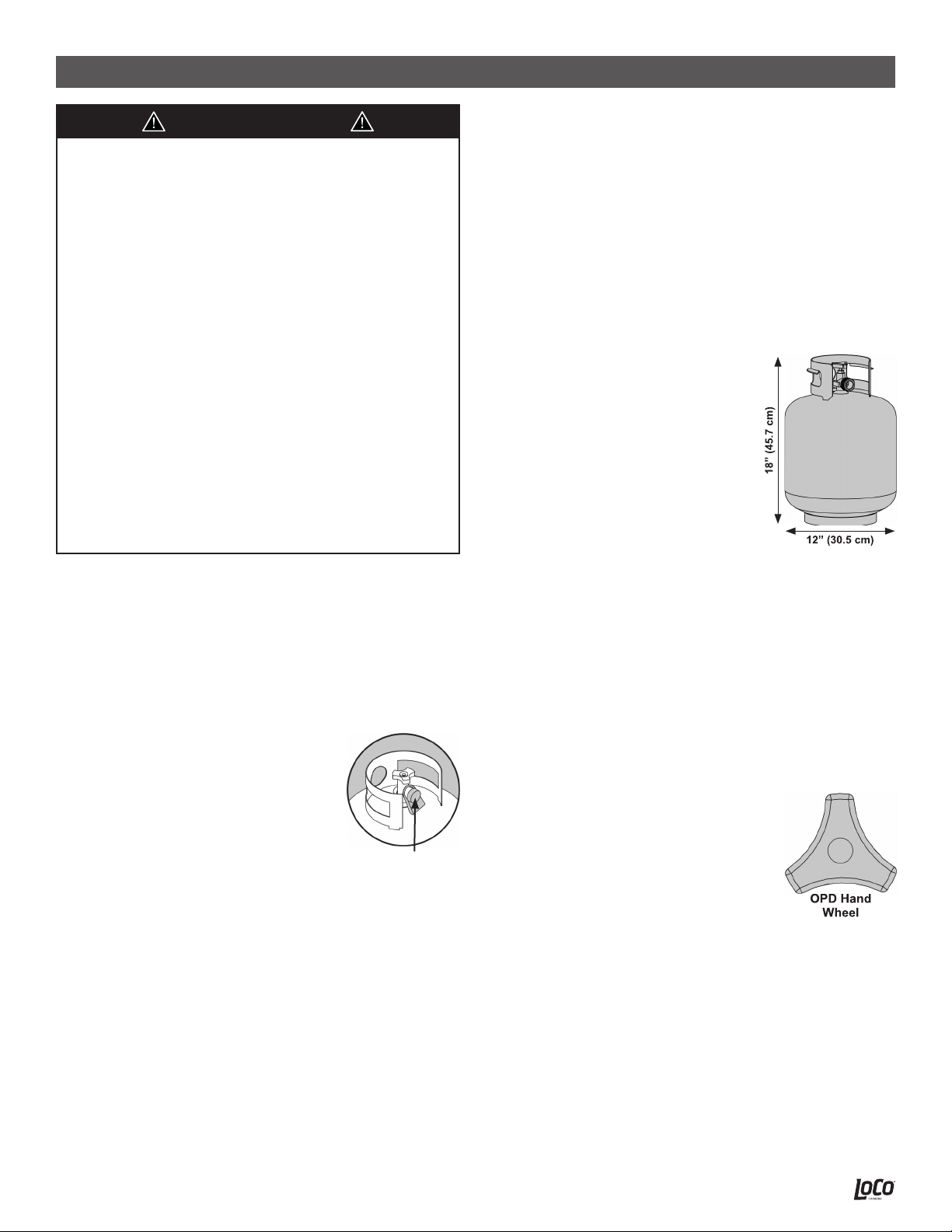

• The appliance

and LP tank must

be arranged so

that any wind blows heat from the appliance

AWAY from the LP tank.

• Keep the fuel supply hose away from any

heated surface(s).

• This appliance is not intended for commercial

use.

• The use of alcohol, prescription drugs or non-

prescription drugs may impair the consumer’s

ability to properly assemble or safely operate

the appliance. Do not operate when under the

inuence.

• When cooking with oil or grease, always have

a Type BC or ABC re extinguisher readily

available.

• In the event of an oil or grease re do not

attempt to extinguish with water. Immediately

call the re department (911). A Type BC or ABC

re extinguisher may, in some circumstances,

contain the re.

• In the event of rain, snow, hail, sleet or other

forms of precipitation while cooking with oil or

grease, cover the cooking pot immediately and

turn o the appliance burners and gas supply.

Never attempt to move the appliance or cooking

pot.

• When cooking, the appliance must always be

on a level, stable, noncombustible surface such

as brick, concrete or dirt and in an area free of

combustible materials. Never use this appliance

on or around surfaces such as asphalt, wood,

dry grass or leaves, vinyl or plastic. These

surfaces are combustible and may melt or catch

re.

• Do not leave the appliance unattended. Keep

children and pets away from the cooking

appliance at all times.

• Do not place an empty cooking pot on the

appliance or allow a lled pot to boil dry while

appliance is in operation. Use caution when

placing anything in the cooking pot while the

appliance is in operation.

• Do not move the appliance while in use. Allow

the cooking pot to cool to 115ºF (46ºC) before

moving or storing.

• This appliance is not intended for and should

never be used as a heater.

• When cooking with oil or grease, the oil

thermometer provided MUST be used. Follow

instructions in this manual for proper installation

and use of the oil thermometer. If the oil

thermometer supplied with this fryer or boiler

has been lost or damaged, a replacement oil

thermometer must be one specied by the

appliance manufacturer.

• Check the thermometer before each use

by inserting it into a pot of boiling water and

ensuring that it registers approximately 212

± 20ºF (100 ± 10ºC). If it does not function

properly, obtain a replacement thermometer

specied by the manufacturer before using the

appliance.

• If the temperature exceeds 400ºF (204ºC) or if

oil begins to smoke, immediately turn the burner