9

SAFETY FIRST2

Please read this manual carefully, adhere to all instructions paying particular attention to the safety

information. For further information or clarification of any of the points made, please contact Logic

Manufacturing Ltd.

he Logic Surface Pro can be towed by any suitable vehicle from U Vs to Landrovers to 4x4

pickups although it is ideally suited to A Vs

he Logic Surface Pro is not suitable for use with A Vs with less than 300cc engine capacity or for

use with leisure or sports models. 4 wheel drive vehicles are recommended. Using an A V with an

attachment introduces additional risks to operating an A V alone, these should be thoroughly

assessed and managed.

SAFE OPERATION

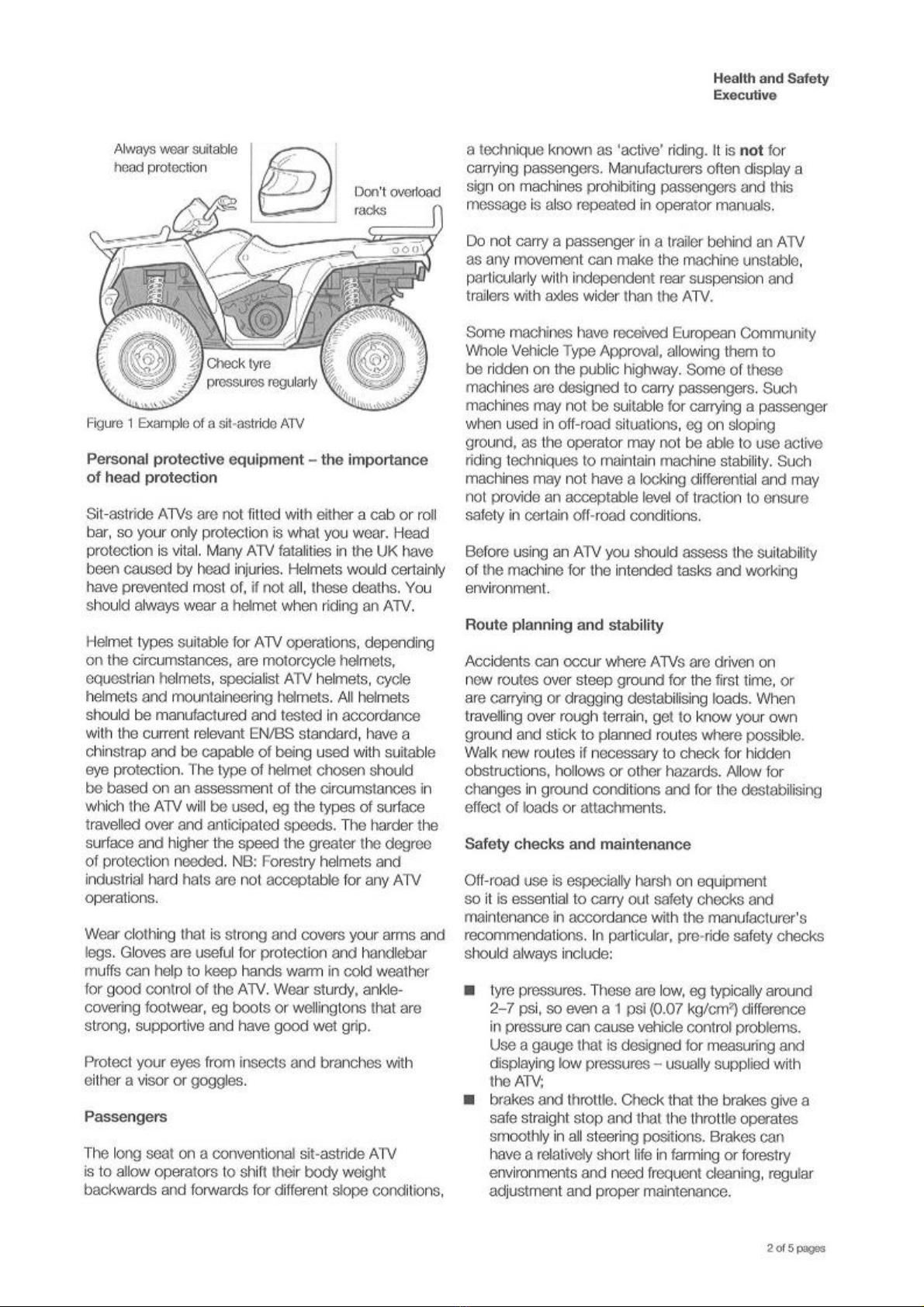

• Protective clothing must be worn, including a helmet with a visor or goggles, gloves, sturdy

ankle covering footwear and strong clothing that covers your arms and legs. Carry a personal

first aid kit including a large wound dressing.

• Never carry passengers on the Logic surface pro. Individuals under 16 years are forbidden to

use this equipment. Ages 17+ must have been trained in towing equipment or trailers. We

strongly recommend these operators have completed the ‘car and trailer driving test —

category B+E’. hey must also receive additional training and supervision on the daily

operation.

• he gross weight of the Logic Surface Pro can be found of the manufacturers plate which is

riveted to the drawbar.

• he Logic Surface Pro should never be driven at speed. Speed should never exceed more

than 20mph.

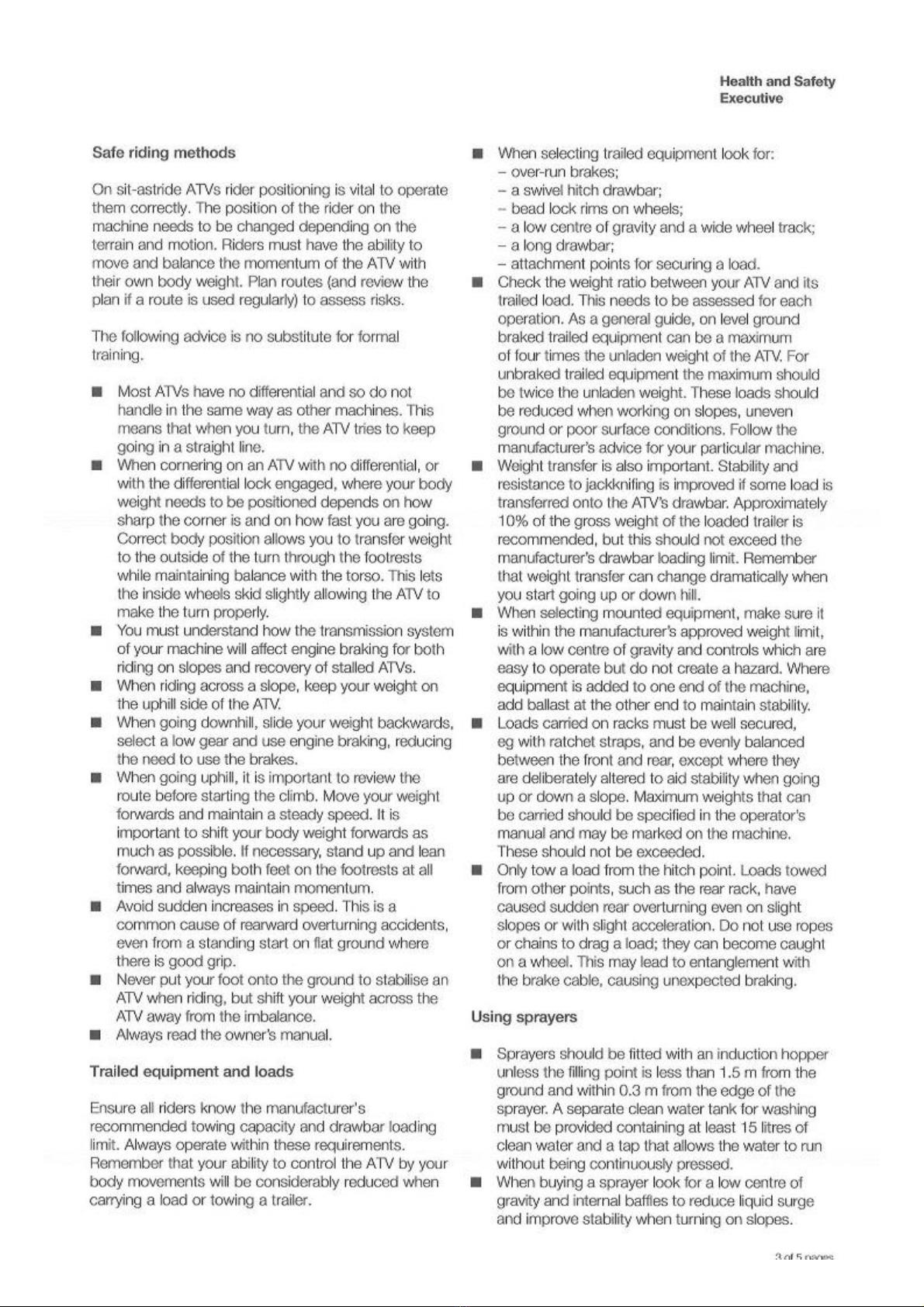

ROUTE PLANNING & ACCESS

• Plan the daily route and access well in advance of using the machine. We recommend you

identify hazards and obstacles including: gates, tracks, public road crossings, field crossings,

hill descents/ascents, sharp corners, unsuitable ground, wet boggy areas, hidden obstacles

(tree stumps, rocks etc). (for more info see HSE Ag info sheet 33 and AFAG701 sheet 39).

• It is the duty of the operators employer, in conjunction with the operators, to identify and plan

the route as part of the health and safety routine planning. A full risk assessment should be

carried out. Logic Manufacturing Ltd accept no responsibility for poor route planning.

If the weather is or has been wet or poor the route should be reassessed before

travelling. Poor weather can affect the terrain being travelled and the handling of the

towing vehicle, especially A Vs

!