9ENGLISH

BRAKE

The brake is dierent to the Gas and Clutch

asit uses the elastomer dampeners found in the

accessory box. The procedure is still straightforward

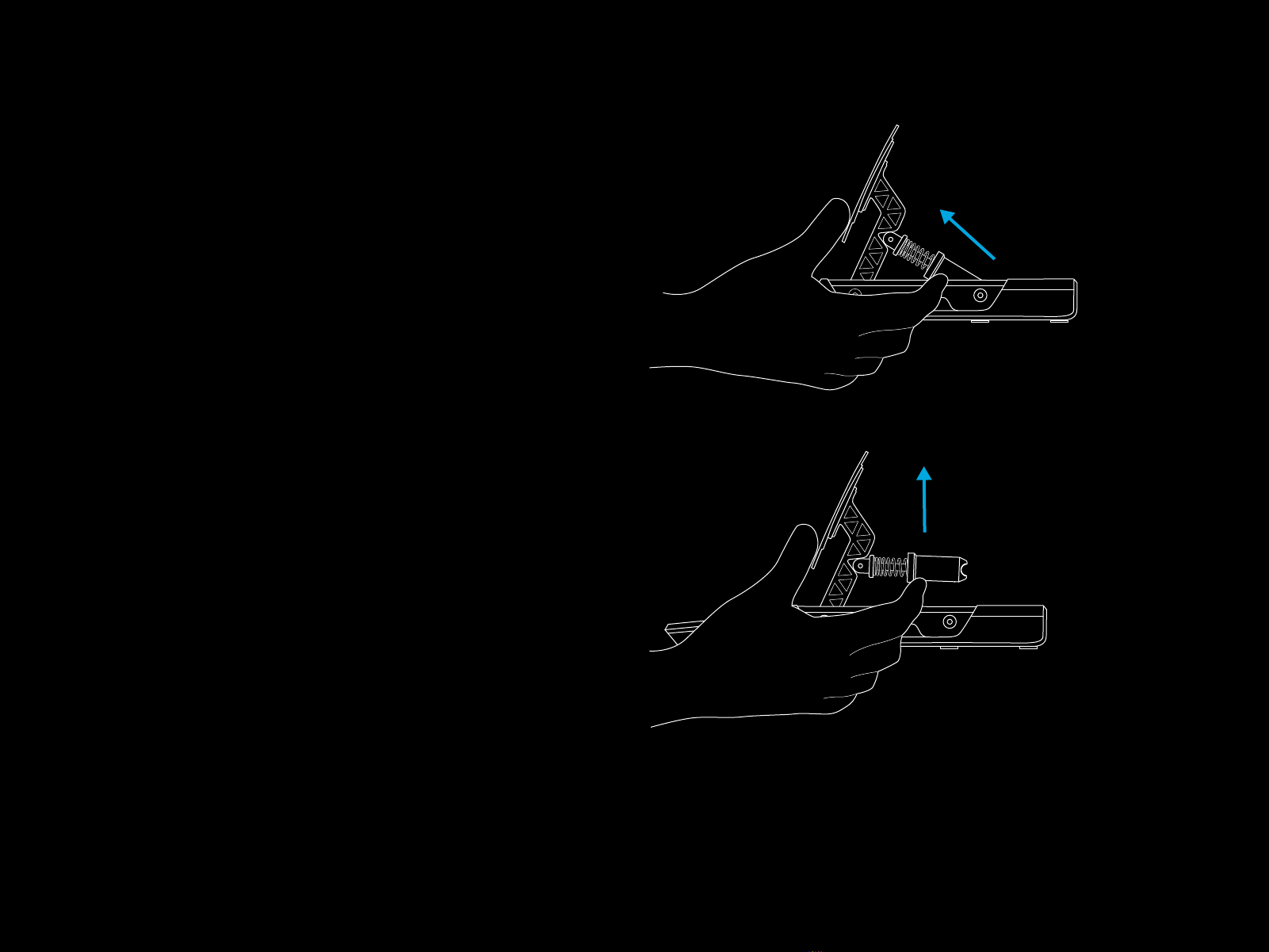

though. Once the piston has been lifted clear from

the pedal module you need to open the piston

inorder to access the elastomer pieces insideit.

Todo this grip the knurled cap at the top of

thepiston in one hand and then unscrew the body

of the piston from the cap.

Once the piston body is removed from the cap,

turnit upside down and shake the elastomer pieces

out. They will be slightly sticky with lubricating

grease so do have something available to wipe

yourhands on.

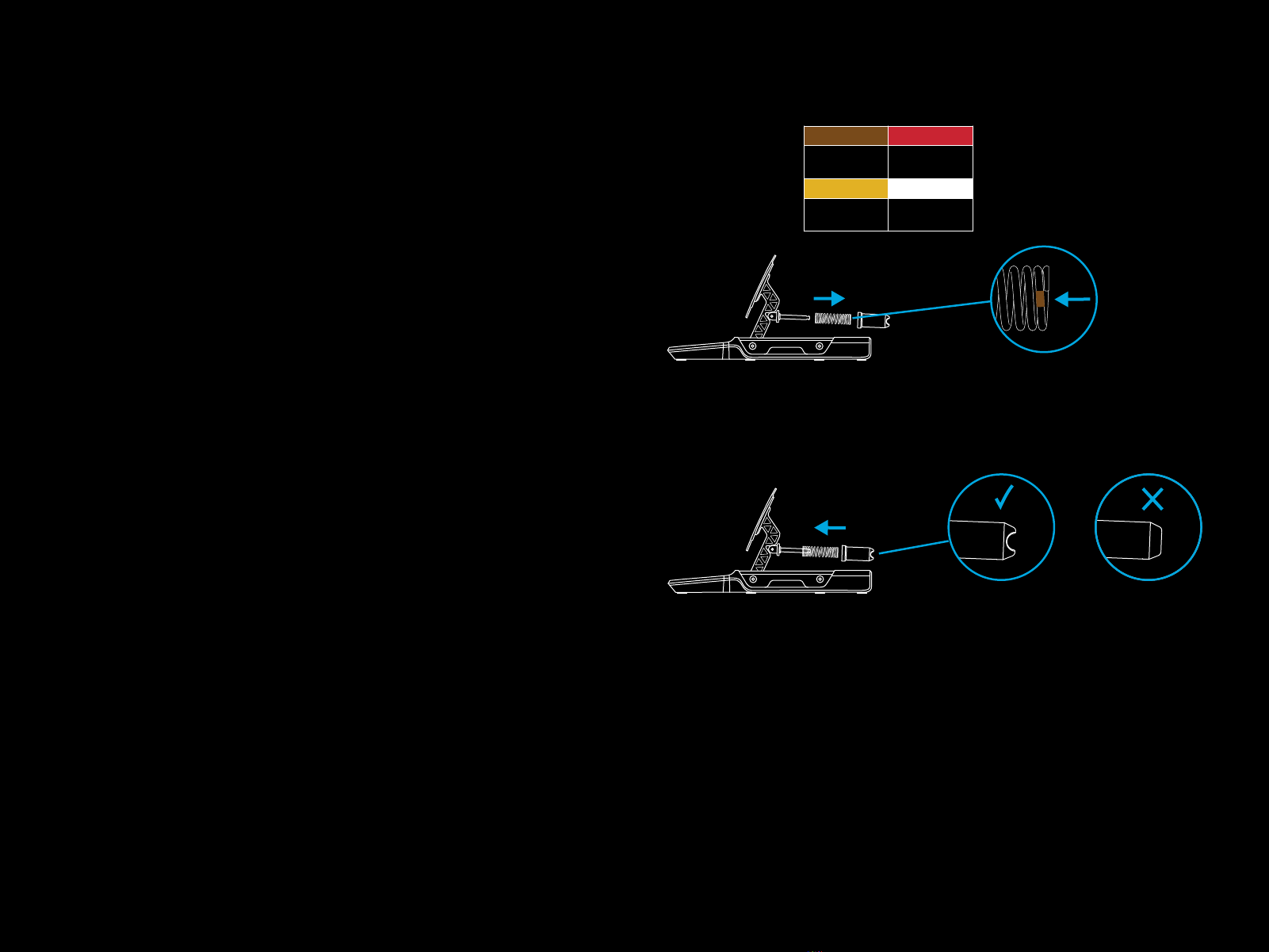

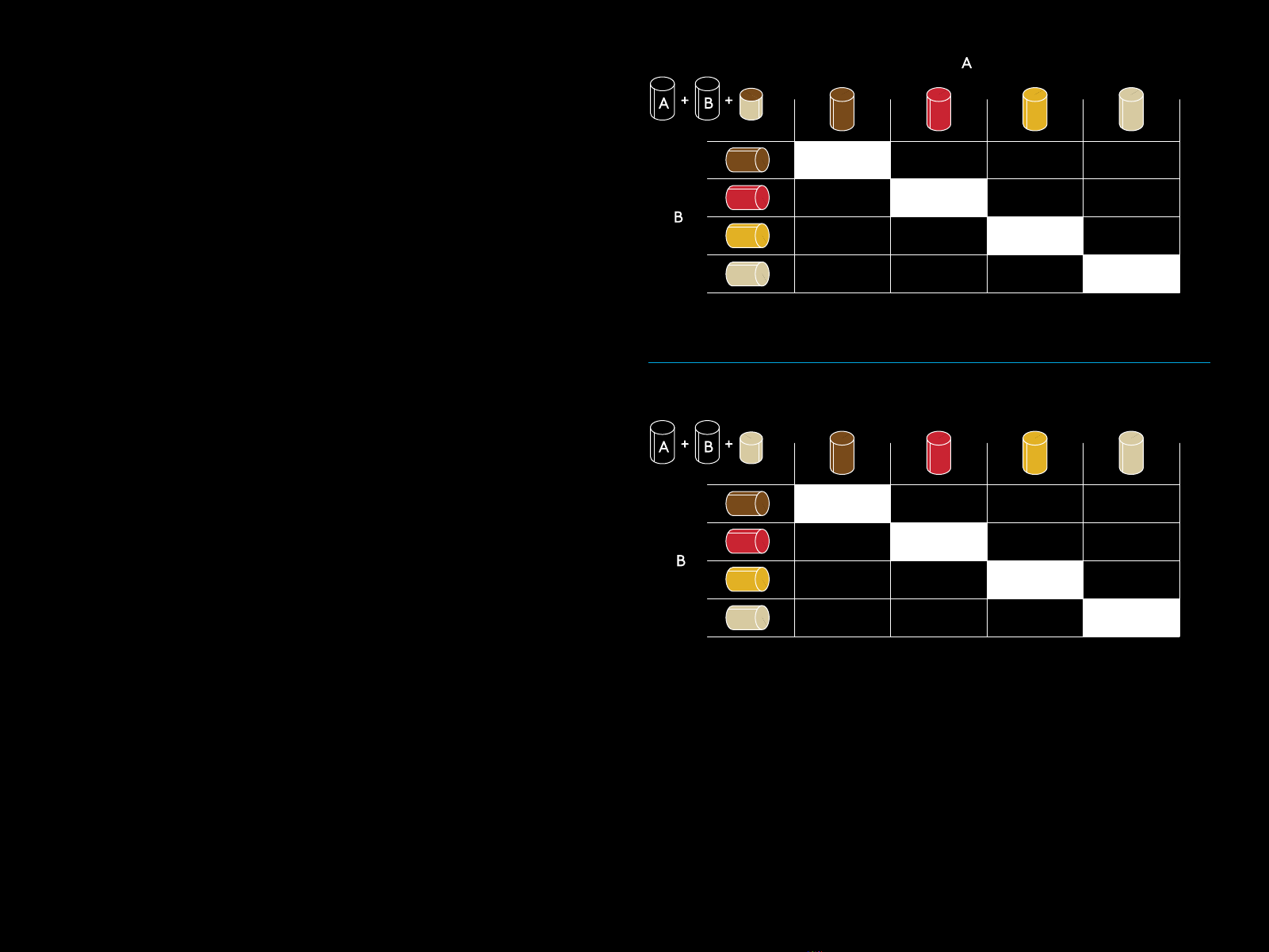

You will notice that there are three pieces of

elastomer or foam in the piston body: two of equal

size and one slightly smaller one. The smaller piece

must always be present in the piston body with

theother two pieces determining the overall feeling

of the brake pedal, enabling you to congure

to be fairly soft with a larger range of travel or,

alternatively, as hard and limited in travel as some

real race cars. Also, the small piece should always

be at the bottom of the piston: