- 2 -

CONTENTS

1 Information for customers ......................................................................................................................... 4

2 Function of the heater:............................................................................................................................... 7

3 Servicing ..................................................................................................................................................... 8

3.1 Control panel ...................................................................................................................................... 8

4 Technical description.................................................................................................................................. 9

4.1 Diagram of: LX ACDC/M+K 100 A,B,C; LX ACDC/M+K 125 A,B,C; LX ACDC/M+K 160 A,B,C; LX

ACDC/M+K 200 A,B,C ..................................................................................................................................... 9

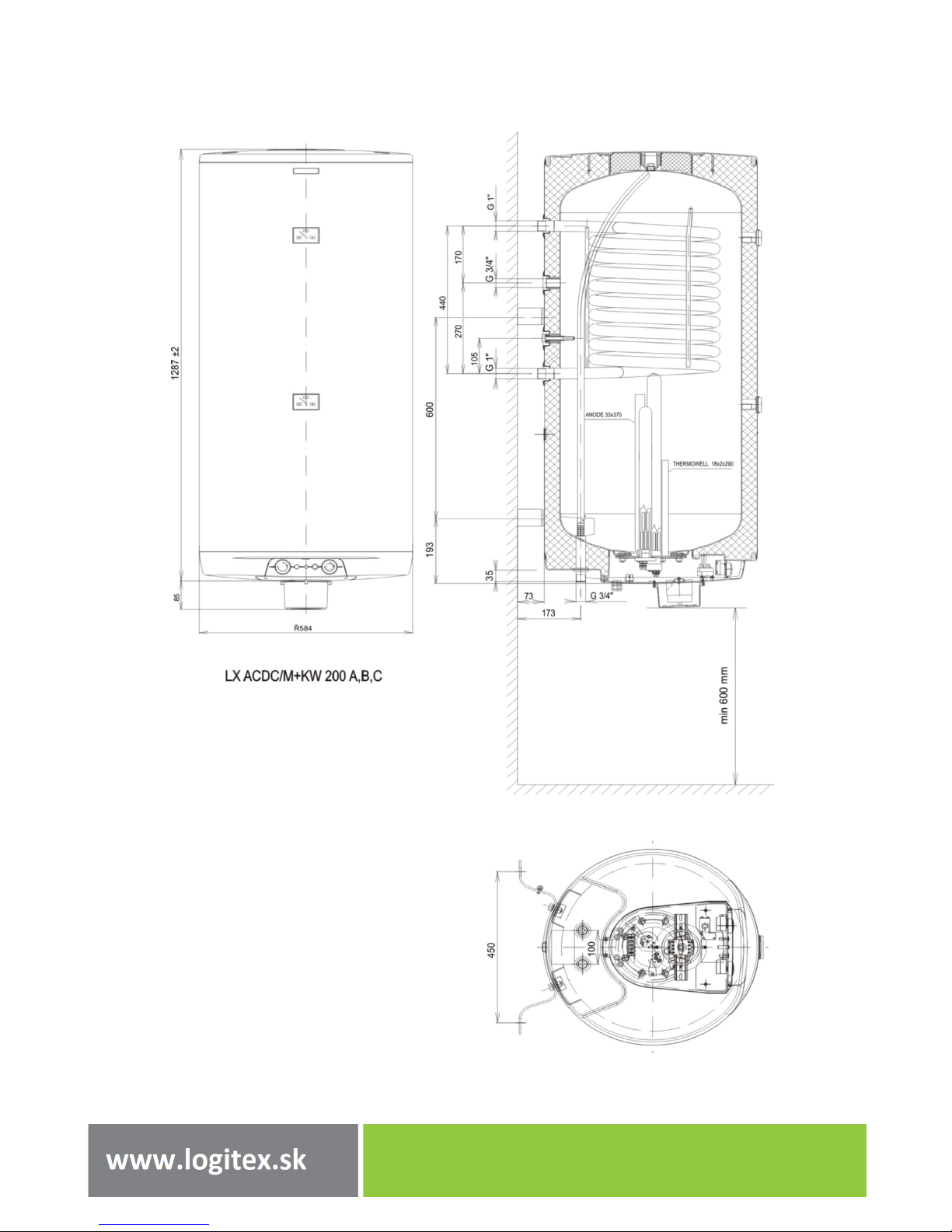

4.2 DIAGRAM OF LX ACDC/M+KW 200 A,B,C ........................................................................................... 9

4.3 DIMENSIONS OF THE LX ACDC/M+KW 200 A,B,C HOT WATER HEATER ........................................... 10

4.4 DIMENSIONS OF: LX ACDC/M+K 100 A,B,C; LX ACDC/M+K 125 A,B,C; LX ACDC/M+K 160 A,B,C; LX

ACDC/M+K 200 A,B,C ................................................................................................................................... 11

5 Operating activity ..................................................................................................................................... 11

6 Accessories ............................................................................................................................................... 12

7 Wall mounting.......................................................................................................................................... 12

8 Plumbing fixture ....................................................................................................................................... 12

9 Connection of a combined heater ............................................................................................................ 14

10 Electric wiring ........................................................................................................................................... 14

10.1 Wiring diagram: ................................................................................................................................ 15

11 Fire-fighting regulations for installation and use of heater ...................................................................... 17

12 Connecting the heat exchanger for LX ACDC/M+KW 200 A,B,C ............................................................... 17

13 Important NoticeS .................................................................................................................................... 18

13.1 Disposal of packaging material and non-functioning product .......................................................... 18