Injection

pump

of

the

plunger

type

with

all

speed

governor and

automatic

timing

device: type

Rotary,wlth fly-weight mechanical governor.

Separate

four

hole

nozzles (360/460)

or

three hole

nozzles (510)

clamped

to

the

cylinder

head.

Forced feed

lubrication

from

camshaft

driven

gear-type

pump

with

built

in

relief

valve.

Full

flow

filter

screwed

to

the

crankcase and pro-

vided

with

an

Internal

relief

valve

which

bypasses

the

oil

flow

when

filter

is

clogged.

CIRCULATING WATER

AND

RADIATOR COOL·

lNG SYSTEM

A

centrifugal

pump,

belt-driven

by

the

crankshaft-mounted drive pulley, forces

the

coolant

flow

which

enters

the

radiator when the

temperature reaches

up

to

thermostat setting.

The cold air drawn by the fan

which

is secured

to

the

water

pump

hub,

cools

the

coolant inside the

radiator.

Direct

electric

starting

with

solenoid engage-

ment,

12

volt

motor

and starting aid

for

low

temperatures.

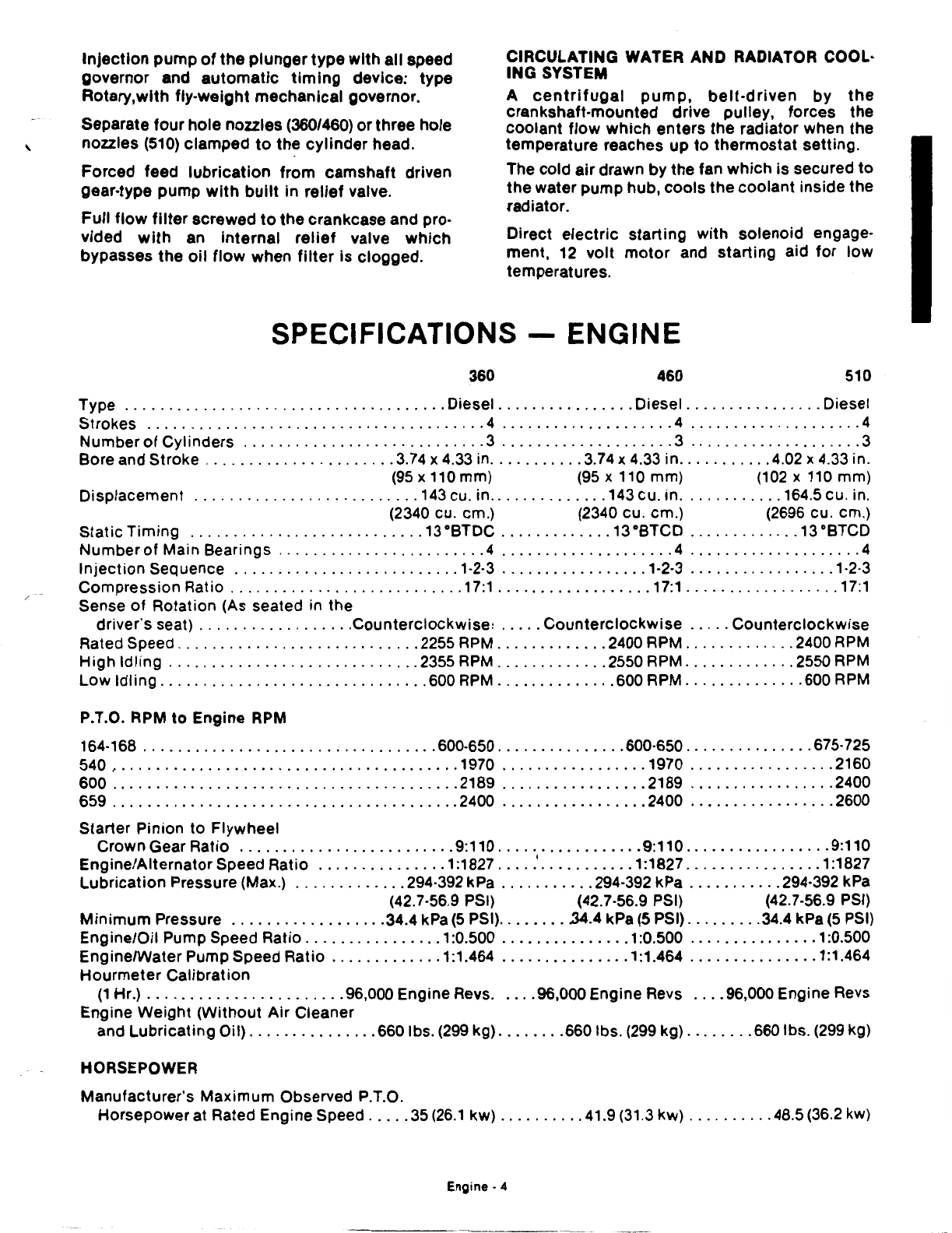

SPECIFICATIONS -ENGINE

360 460 510

Type

.....................................

Diesel

................

Diesel

................

Diesel

Strokes

.......................................

4

....................

4

....................

4

Number

of

Cylinders

............................

3

....................

3

....................

3

Bore and Stroke

......................

3.74 x

4.33

in

...........

3.74

x 4.33 in

...........

4.02 x 4.33 in.

(95

x 110 mm)

(95

x

110

mm)

(102

x

110

mm)

Displacement

..........................

143

cu. in

..............

143 cu. in

............

164.5 cu. in.

(2340 cu. em.) (2340 cu. em.)

(2696

cu. em.)

Static Timing

...........................

13°8TDC

.............

13

°8TCD

.............

13

°8TCD

Number

of

Main Bearings

........................

4

....................

4

....................

4

Injection

Sequence

..........................

1-2-3

.................

1-2·3

.................

1-2-3

Compression Ratio

...........................

17:1

..................

17:1

..................

17:1

Sense

of

Rotation (As seated in the

driver's seat)

..................

Counterclockwise:

.....

Counterclockwise

.....

Counterclockwise

Rated Speed

............................

2255

RPM

.............

2400

RPM

.............

2400

RPM

High Idling

.............................

2355

RPM

.............

2550

RPM

.............

2550

RPM

Low Idling

...............................

600

RPM

..............

600

RPM

..............

600

RPM

P.T.O. RPM

to

Engine

RPM

164-168

..................................

600-650

...............

600·650

...............

675-725

540 '

.......................................

1970

.................

1970

.................

2160

600

........................................

2189

.................

2189

.................

2400

659

........................................

2400

.................

2400

..........

-

......

2600

Starter Pinion to Flywheel

Crown Gear Ratio

.........................

9:110

.................

9:110

.................

9:110

Engine/AlternatorSpeed Ratio

...............

1:1827

....

.'

...........

1:1827

................

1:1827

Lubrication Pressure (Max.)

.............

294-392 kPa

...........

294-392 kPa

...........

294-392 kPa

(42.7-56.9 PSI) (42.7-56.9 PSI) (42.7-56.9

PSI)

Minimum

Pressure

..................

34.4 kPa

(5

PSI)

........

.34.4

kPa

(5

PSI)

.........

34.4 kPa

(5

PSI)

Engine/Oil Pump Speed Ratio

................

1:0.500

...............

1:0.500

...............

1:0.500

Engine/Water Pump Speed Ratio

.............

1:1.464

...............

1:1.464

...............

1:1.464

Hourmeter Calibration

(1

Hr.)

.......................

96,000 Engine Revs. .

...

96,000 Engine Revs

....

96,000 Engine Revs

Engine Weight (Without Air Cleaner

and Lubricating Oil)

...............

660 lbs.

(299

kg)

........

660 lbs.

(299

kg)

........

660 lbs.

(299

kg)

HORSEPOWER

Manufacturer's Maximum Observed P.T.O.

Horsepowerat Rated Engine Speed

.....

35

(26.1

kw)

..........

41.9

(31

.3

kw)

..........

48.5

(36.2

kw)

Engine- 4

-----

--------

---