!

Handy tips:

1. Put your system on a strong, firm work surface. (A bendy table may

result in a curved cut).

2. Make sure it’s at a comfortable working height.

3. Place the System perpendicular to you – not across you.

4. Your position should be slightly to one side of the System so as to allow

your arm to move smoothly with the cutting motion. (R-handers stand

to the L, LH to the R).

5. Work on the back of the mountboard at all times.

6. Remember to rotate the mountboard around for each cut so that the

bevels are not inverted.

7. If the mount is to be fixed flat to the wall make the border the same

width all around. However, if the picture is to be hung with a hook, it will

tilt slightly, creating an illusion of a shorter looking bottom border. To

overcome this, increase the bottom border width a little. This is a

dropped border mount.

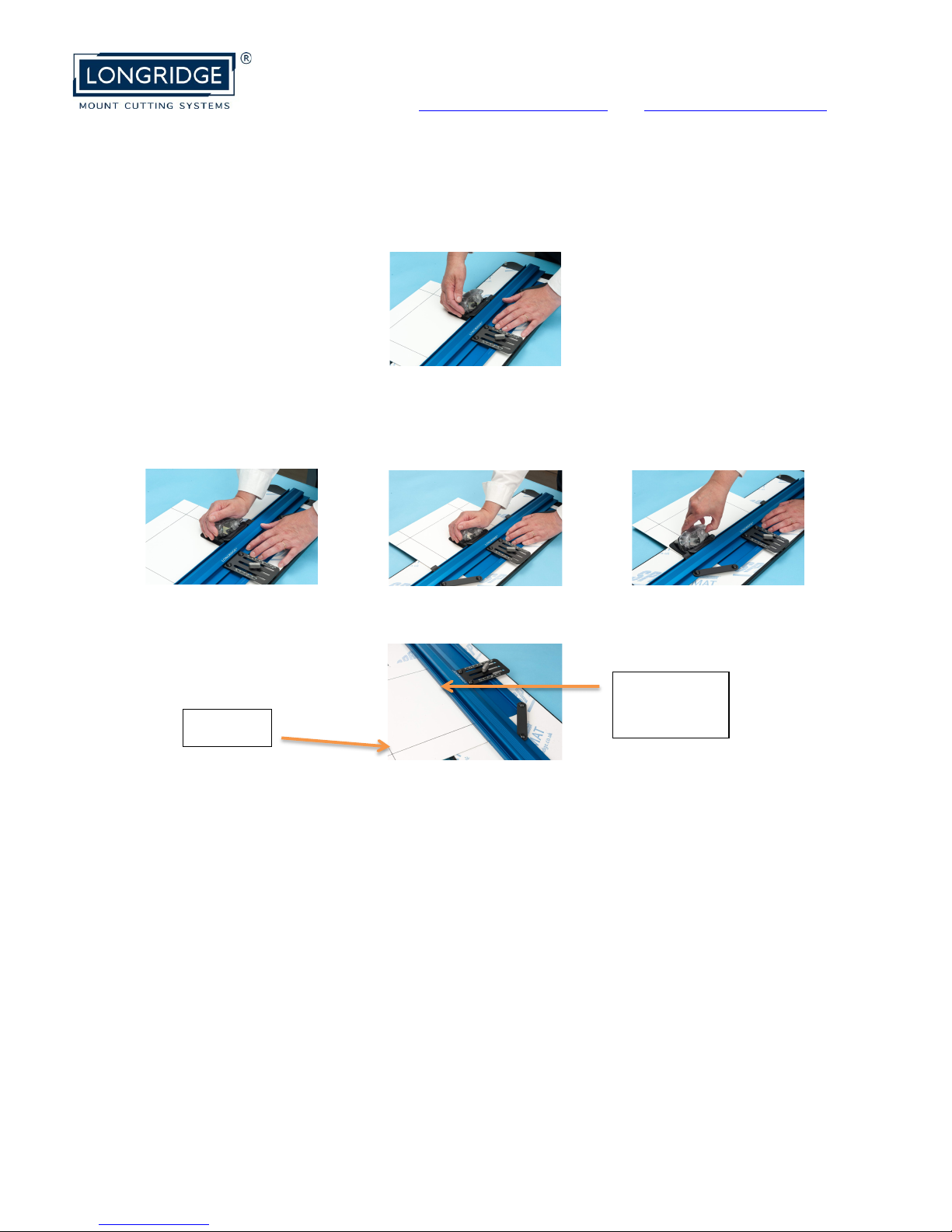

Cutting the Exterior

The Straight Cutter is used to cut sheet mountboard down to size, in

preparation for the window aperture.

1. Take out the Cutter Stops.

2. Turn the Guide Rail over and remove the Mount Stop by slackening the

screw with the screwdriver and unlocking the cam.

3. Replace the Guide Rail and set the parallel bar to maximum.