10/09 Page 3

Copyright © 2009 Lortone, Inc

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 U.S.A

Phone: 425-493-1600 • www.lortone.com

OPERATION

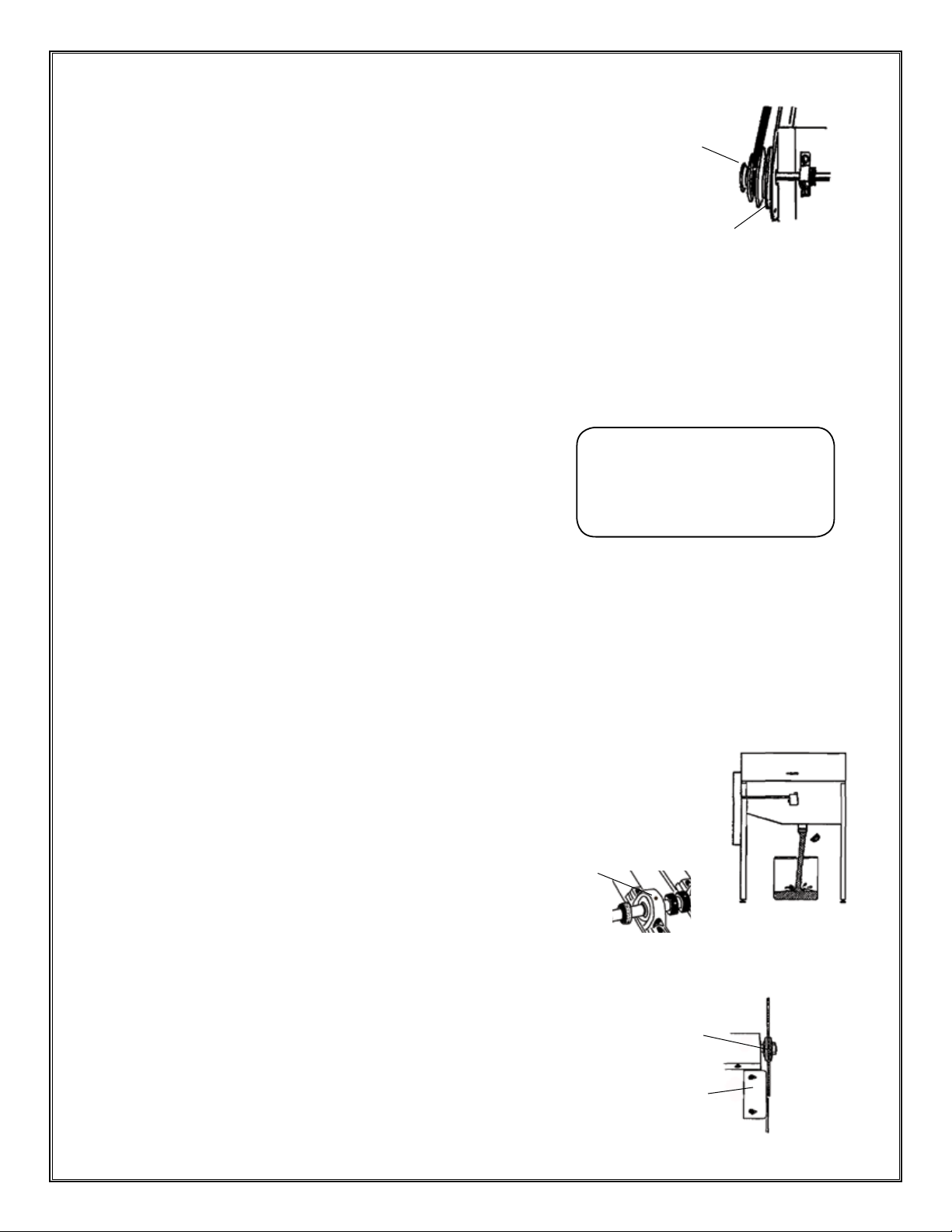

Setting Feed Rate:

Select the feed rate appropriate for the material, coolant and blade.

Select slow feed rate for hard materials or thick cross sections.

CAUTION: Too fast a feed rate can result in damage to the blade

or saw and is not covered under warranty.

SLOWEST feed rate - Move the feed belt to the LARGEST pulley.

MEDIUM feed rate - Move the feed belt to the MIDDLE pulley.

FASTEST feed rate - Move the feed belt to the SMALLEST pulley.

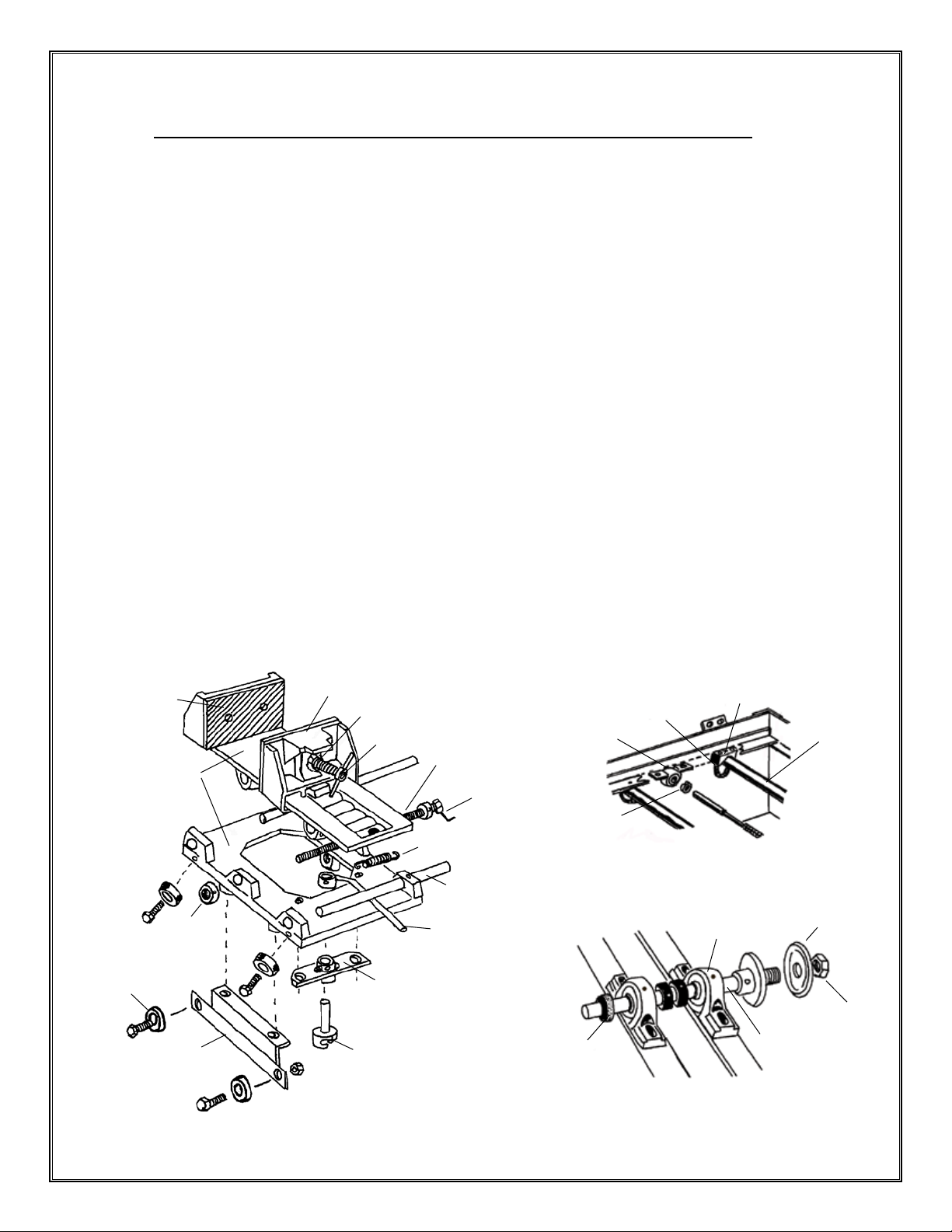

Clamping Material:

Make sure the switch on Control Box is in the “OFF” position (toward saw) before opening the hood.

Clamp material securely in vise. Check for looseness of material and re-tighten if necessary.

Adjust cross feed and hand tighten the carriage lock screw.

Check to be sure that material will clear the arbor shaft cover and the blade anges.

To release carriage, pull half nut lever toward control box. Slide the carriage to desired position and release

the half nut lever. Make sure the lever is fully engaged.

Adjust shutoff chain for desired length of cut.

To Start Saw:

Note: The feed is engaged anytime the saw is running.

Close hood and turn switch to “ON” position.

IMPORTANT- DO NOT LEAVE SAW UNATTENDED

Listen for changes in operating noise. Sudden changes can indicate damaged material or blade.

Over-heating of the drive motor can result in tripping of the safety overload protector. To prevent blade & saw

damage, IMMEDIATELY turn off the “Power” switch. Inspect the machine and blade for damage and correct

any problems before continuing. When cool, press the red reset button on the drive motor to reset the protector.

At End of Cut:

Push power switch toward saw to “OFF” position before opening the hood.

Remove the cut slab. Inspect the remaining material to make sure it is secure in the vise.

Loosen carriage lock screw and advance the carriage by turning the cross-feed wheel.

Each turn advances the cross-feed carriage approximately 1/16 inch (.062).

CLEANING & MAINTENANCE

The saw should be cleaned periodically when sediment builds up to a depth of 1/4”.

Remove the drain cap from the saw case and drain the oil.

Wipe sludge from the case and power feed screw.

Replace the drain cap and add clean or ltered oil.

Bearings come pre-greased from factory. If saw is heavily used,

bearings can be greased through hole in the bearing housing*.

BLADE REPLACEMENT

NOTE: This saw requires and 18” blade with a 3/4” arbor hole.

Remove the arbor nut, outer blade ange, and blade.

Clean the anges.

Install the new blade carefully.

Replace the outer ange and arbor nut and tighten securely.

Do Not Overtighten!

Adjust slab catcher to clear blade by 1/8”.

•

•

•

•

•

•

•

•

•

•

•

•

•

CAUTION

Do not operate saw with hood open.

Turn off power switch and unplug

saw prior to opening hood.

Failure to follow these instructions

can result in serious injury.

•

•

•

•

•

•

•

•

•

•

Drain used Oil &

dispose of properly.

Install Blade & Outer

Flange and tighten

Arbor Nut securely

Slab

Catcher

FASTEST

Feed Rate

SLOWEST

Feed Rate

•

* Bearing Housing