Contents

Translation of the original instructions

2

Contents

1 INTRODUCTION......................................................................................................................... 5

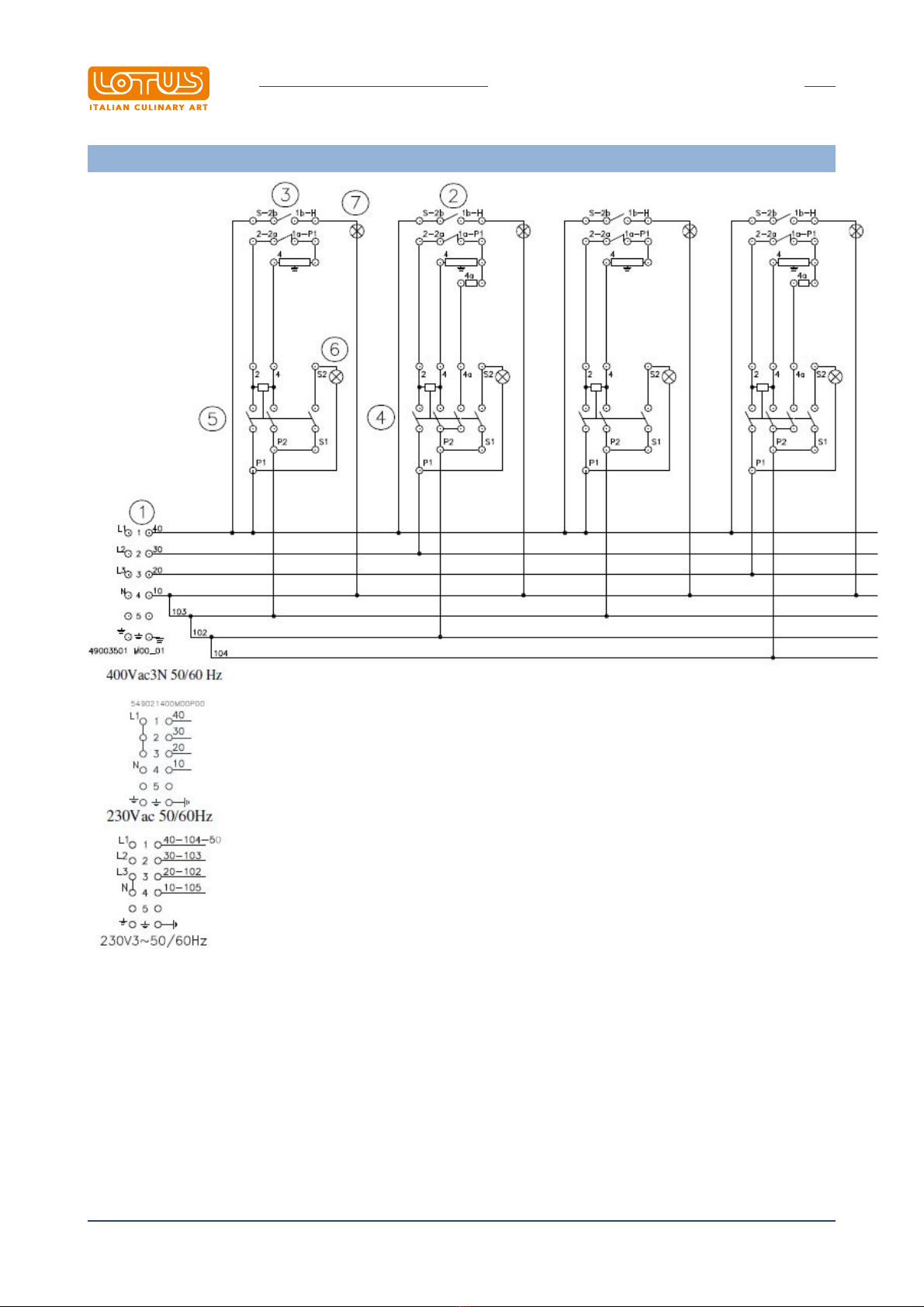

1.1 Installation drawing...................................................................................................................... 5

1.2 Components................................................................................................................................. 6

2 GENERAL INFORMATION......................................................................................................... 14

2.1 Declaration of compliance............................................................................................................ 14

2.2 User information, RAEE Directive on waste electrical and electronic equipment ........................ 15

2.3 Technical data table..................................................................................................................... 15

3 INSTALLATION........................................................................................................................... 16

3.1 Delivery checks ............................................................................................................................ 16

3.2 Removing the packaging ............................................................................................................. 16

3.3 Mechanical installation ................................................................................................................. 16

3.4 Electrical/gas connections ........................................................................................................... 16

4 BURNERS TECHNICAL DATA TABLE (ITGB).......................................................................... 21

4.1 Burners technical data table ........................................................................................................ 21

5 INSTRUCTIONS FOR USE......................................................................................................... 22

5.1 General information ..................................................................................................................... 22

5.2 Lighting and adjusting the open rings.......................................................................................... 22

5.3 Starting the main burner and adjusting the temperature.............................................................. 22

5.4 Turning the appliance off.............................................................................................................. 22

5.5 Lighting and adjusting the open rings.......................................................................................... 22

5.6 Glass-ceramic cooker hob........................................................................................................... 23

5.7 Lighting and regulating gas oven burner...................................................................................... 24

5.8 Igniting the Grill burner................................................................................................................. 25

5.9 Oven lighting ............................................................................................................................... 25

5.10 Igniting and adjusting the static oven ........................................................................................... 25

5.11 Igniting and adjusting the multi-function electric oven ................................................................. 26

5.12 Cooking table for the fan oven ..................................................................................................... 28

5.13 Gas oven cooking table ............................................................................................................... 29

5.14 Gas grill cooking table.................................................................................................................. 30

5.15 Electric grill cooking table ............................................................................................................ 30

6 MAINTENANCE.......................................................................................................................... 31

6.1 Routine......................................................................................................................................... 31

6.2 Changing the open ring nozzles (fig. C)....................................................................................... 31

6.3 Substituting the nozzle in the oven burner ................................................................................... 31

6.4 Replacing the grill burner nozzle.................................................................................................. 32

6.5 Replacing the oven lamp ............................................................................................................. 32

6.6 Minimum setting ........................................................................................................................... 32