8

IX

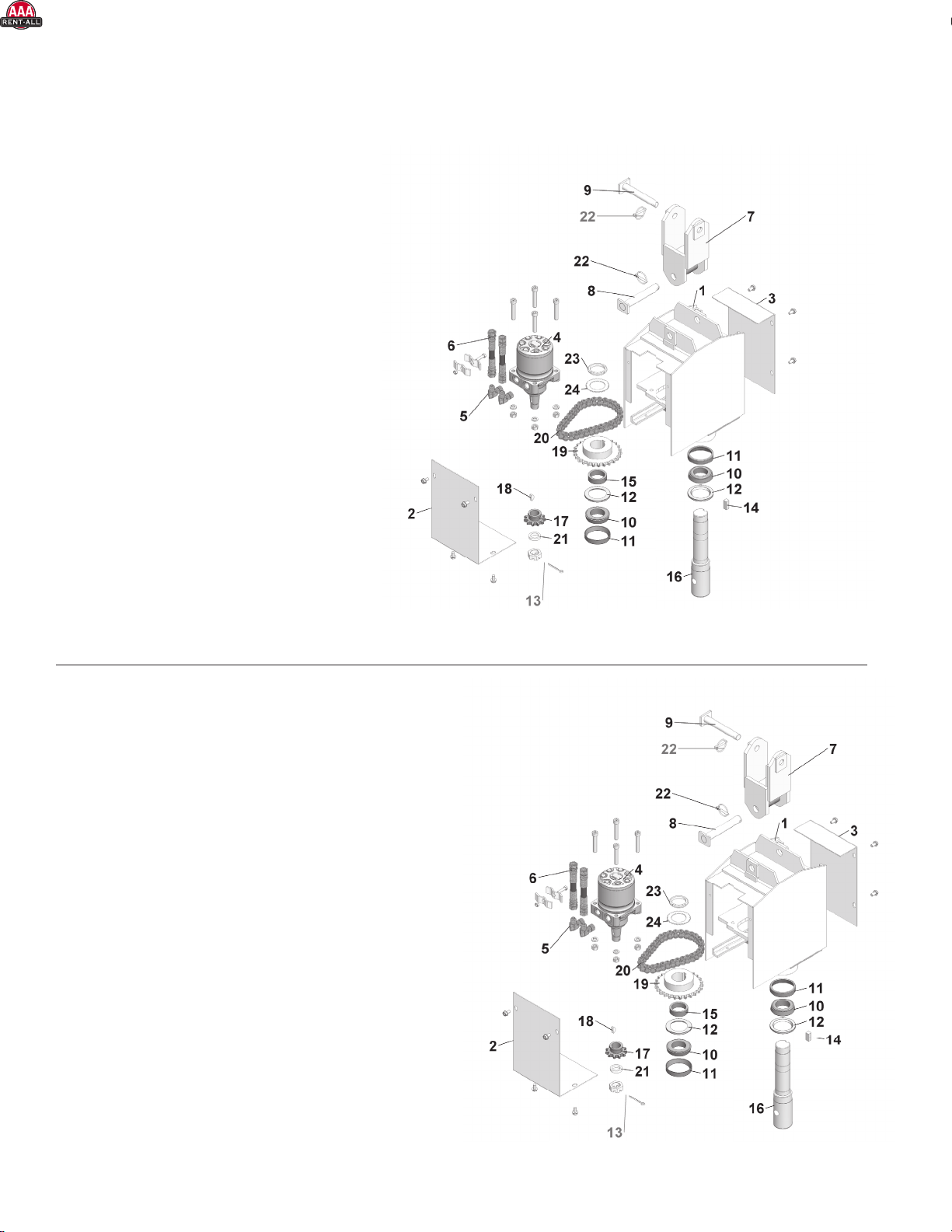

UNIT PARTS DIAGRAMS

with SPEED & POWER RATINGS

MODEL 750C Classic

Operational Range:

Oil Flow 6 to 20 GPM (23 to 76 Lpm)

Pressure 2,000 to 3,300 PSI (13,790 to 22,737 Kpa)

Digging Conditions Light

Typical Auger Sizes 6” (15 cm), 9” (23 cm), 12” (30 cm), 15” (38 cm), and 18” (46 cm) diameter

Ref. # Part # Description

1 75-001CL Housing

2 75-002A Front cover

4 75-004 Rear cover

7 MEL-12K Hydraulic motor

8 10-008E 90º elbow (2 Required)

9 10-009 Hose nipple and clamp assembly

11 10-112 Universal connecting link (includes 10-013S)

12 10-013CL Clevis pin

13 10-013S Clevis pin

14 10-368A Bearing cone (2 required)

15 10-362A Bearing cup (2 required)

16 10-25028 Seal (2 required)

17 N-10 Nut for output shaft

18 W-10 Washer for output shaft

19 10-15 Key for output shaft

20 TR-507 Spacer for output shaft

21 CR255-13 Round output shaft with nut, lockwasher and key

HE255-13 Hex output shaft with nut, lockwasher, and key

22 11-60T Motor sprocket (includes 10-17W key)

22a 10-17W Key for motor shaft

23 26-60 Driven sprocket (includes key)

24 34-60H Drive chain

25 10-14CL Motor shaft spacer

C-60H Chain connecting link

L-78 7/8” pin to attach auger to round (29/16”) shaft drive unit

L-50 3/4” pin to attach auger to hex (2”) shaft drive unit

SK-92 Seal kit for motor

MODEL 500CL

Operational Range:

Oil Flow 5 to 15 GPM (19 to 57 Lpm)

Pressure 1,700 to 3,300 PSI (11,720 to 22,737 Kpa)

Digging Conditions Light

Typical Auger Sizes 6” (15 cm), 9” (23 cm), 12” (30 cm), 15” (38 cm)

Ref. # Part # Description

1 75-001CL Housing

2 75-002A Front cover

4 75-004 Rear cover

7 MEL-12K Hydraulic motor

8 10-008E 90º elbow (2 Required)

9 10-009 Hose nipple and clamp assembly

11 10-112 Universal connecting link (includes 10-013S)

12 10-013CL Clevis pin

13 10-013S Clevis pin

14 10-368A Bearing cone (2 required)

15 10-362A Bearing cup (2 required)

16 10-25028 Seal (2 required)

17 N-10 Nut for output shaft

18 W-10 Washer for output shaft

19 10-15 Key for output shaft

20 TR-507 Spacer for output shaft

21 CR255-13 Round output shaft with nut, lockwasher and key

HE255-13 Hex output shaft with nut, lockwasher, and key

22 11-60T Motor sprocket (includes 10-17W key)

22a 10-17W Key for motor shaft

23 20-60 Driven sprocket (includes key)

24 30-60H Drive chain

25 10-14CL Motor shaft spacer

C-60H Chain connecting link

L-78 7/8” pin to attach auger to round (29/16”) shaft drive unit

L-50 3/4” pin to attach auger to hex (2”) shaft drive unit

SK-92 Seal kit for motor

MODEL 500 Classic

Operational Range:

Oil Flow 5 to 15 GPM (19 to 57 Lpm)

Pressure 1,700 to 3,300 PSI (11,720 to 22,737 Kpa)

Digging Conditions Light

Typical Auger Sizes 6” (15 cm), 9” (23 cm), 12” (30 cm), 15” (38 cm)

Ref. # Part # Description

1 75-001CL Housing

2 75-002A Front cover

3 75-004 Rear cover

4 MEL-12K Hydraulic motor

5 10-008E 90°elbow (2 Required)

6 10-009 Hose nipple and clamp assembly

7 10-112 Universal connecting link (Includes 10-013S)

8 10-013CL Clevis pin (Includes HANG-4)

9 10-013S Clevis pin (Includes HANG-4)

10 10-368A Bearing cone (2 Required)

11 10-362A Bearing cup (2 Required)

12 10-25028 Seal (2 Required)

13 N-12 Nut for motor shaft (Includes cotter key)

14 10-15 Key for output shaft

15 TR-507 Spacer for output shaft

16 CR255-13 Round output shaft

HE255-13 Hex output shaft

17 11-60T Motor sprocket (Includes 10-17W)

18 10-17W Key for motor shaft

19 20-60 Driven sprocket (Includes 10-15)

20 30-60H Drive chain

21 10-14 Motor shaft spacer

22 HANG-4 Lynch pin

23 N-10 Nut for output shaft

24 W-10 Lockwasher for output shaft

C-60H Chain connecting link

L-78 7/8” pin to attach auger to round (2 9/16”) shaft drive unit

L-50 1/2” pin to attach auger to hex (2”) shaft drive unit

SK-92 Seal kit for motor

MODEL 750 Classic

Operational Range:

Oil Flow 6 to 20 GPM (23 to 76 Lpm)

Pressure 2,000 to 3,300 PSI (13,790 to 22,737 Kpa)

Digging Conditions Light

Typical Auger Sizes 6” (15 cm), 9” (23 cm), 12” (30 cm), 15” (38 cm), and 18” (46 cm) diameter

Ref. # Part # Description

1 75-001CL Housing

2 75-002A Front cover

3 75-004 Rear cover

4 MEL-12K Hydraulic motor

5 10-008E 90°elbow (2 Required)

6 10-009 Hose nipple and clamp assembly

7 10-112 Universal connecting link (Includes 10-013S)

8 10-013CL Clevis pin (Includes HANG-4)

9 10-013S Clevis pin (Includes HANG-4)

10 10-368A Bearing cone (2 Required)

11 10-362A Bearing cup (2 Required)

12 10-25028 Seal (2 Required)

13 N-12 Nut for motor shaft (Includes cotter key)

14 10-15 Key for output shaft

15 TR-507 Spacer for output shaft

16 CR255-13 Round output shaft

HE255-13 Hex output shaft

17 11-60T Motor sprocket (Includes 10-17W)

18 10-17W Key for motor shaft

19 26-60 Driven sprocket (Includes 10-15)

20 34-60H Drive chain

21 10-14 Motor shaft spacer

22 HANG-4 Lynch pin

23 N-10 Nut for output shaft

24 W-10 Lockwasher for output shaft

C-60H Chain connecting link

L-78 7/8” pin to attach auger to round (2 9/16”) shaft drive unit

L-50 1/2” pin to attach auger to hex (2”) shaft drive unit

SK-92 Seal kit for motor

*Always follow manufacturer instructions*

*AAA Rent-All 225-291-1356*