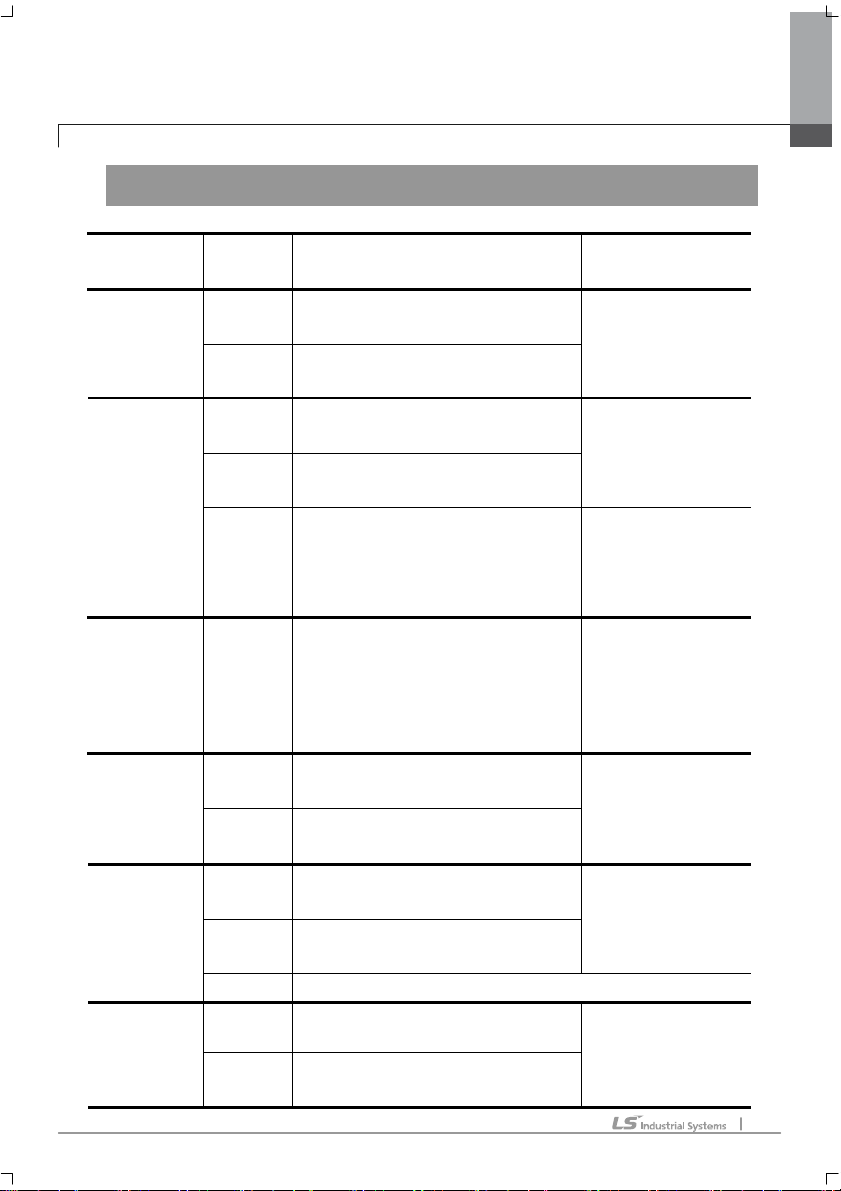

4

Please put to

Please put to Please put to

Please put to earth;

earth;earth;

earth;

it may result in electric shock.

Please do not

Please do not Please do not

Please do not attempt

attemptattempt

attempt to disassemble even when the pow

to disassemble even when the pow to disassemble even when the pow

to disassemble even when the power not

er not er not

er not

applied;

applied;applied;

applied;

it may result in electric shock by charging current

remained in the product.

Please do not short

Please do not shortPlease do not short

Please do not short-

--

-circuit the secondary part of

circuit the secondary part of circuit the secondary part of

circuit the secondary part of PT;

PT;PT;

PT;

it may result

in fire.

Please do not disconnect

Please do not disconnectPlease do not disconnect

Please do not disconnect the secondary part of CT;

the secondary part of CT; the secondary part of CT;

the secondary part of CT;

it may result

in fire or explosives.

Please do not wire or operate with wet hands;

Please do not wire or operate with wet hands;Please do not wire or operate with wet hands;

Please do not wire or operate with wet hands;

it may result in electric

shock.

Please do not use any damaged cable;

Please do not use any damaged cable;Please do not use any damaged cable;

Please do not use any damaged cable;

it may result in electric shock.

Please use the ring terminal

Please use the ring terminal Please use the ring terminal

Please use the ring terminal when wiring

when wiringwhen wiring

when wiring the cable;

the cable; the cable;

the cable;

it may result in

electric shock by bare wire.

Safety caution for installation &

Safety caution for installation & Safety caution for installation &

Safety caution for installation & terminal

terminalterminal

terminal wiring

wiring wiring

wiring

Apply the rated voltage to the power supply terminal;

Apply the rated voltage to the power supply terminal; Apply the rated voltage to the power supply terminal;

Apply the rated voltage to the power supply terminal;

it may result in

property damage or fire.

Please keep

Please keep Please keep

Please keep away product

away productaway product

away product from screws, metals, water, or oi

from screws, metals, water, or oi from screws, metals, water, or oi

from screws, metals, water, or oil;

l;l;

l;

it may

result in fire.

Please keep the rated load and polarity of input & output contacts;

Please keep the rated load and polarity of input & output contacts; Please keep the rated load and polarity of input & output contacts;

Please keep the rated load and polarity of input & output contacts;

it

may result in property damage or fire.

•

••

• Please wire to the terminal block after checking the terminal

Please wire to the terminal block after checking the terminal Please wire to the terminal block after checking the terminal

Please wire to the terminal block after checking the terminal number;

number;number;

number;

it

may result in property damage or fire.

Warning