Email: tech@lsm.com.au Web: www.lsm.com.au

TABLE OF CONTENTS

USER MANUAL _______________________________________________1

LSM TyreGuard®RV360 ________________________________________1

LSM TYREGUARD® RV360_______________________________________________ 2

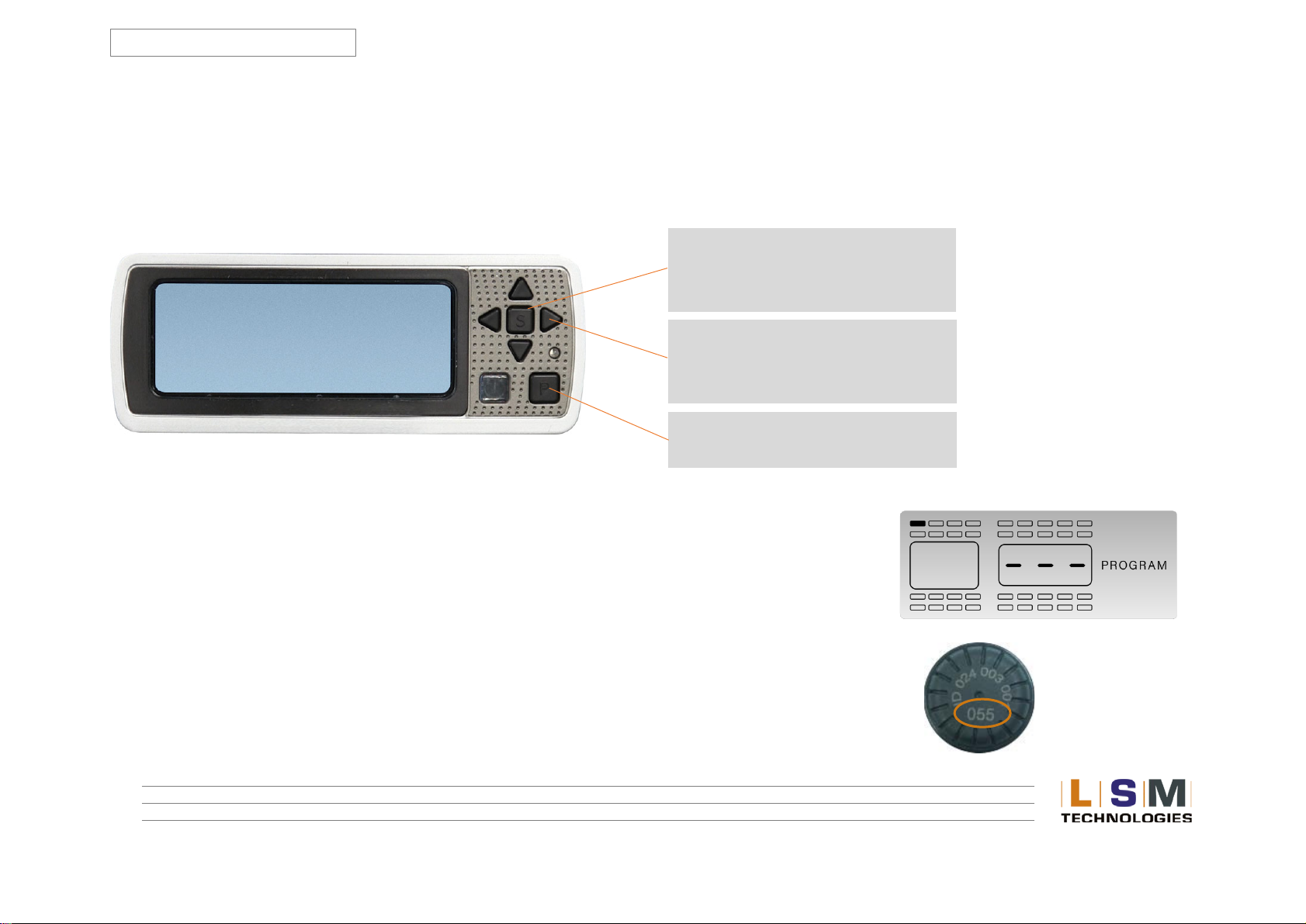

SYSTEM COMPONENTS ________________________________________________ 6

GLOSSARY OF TERMS __________________________________________________ 7

II. SETUP AND INSTALLATION ______________________________________8

INSTALLING THE MONITOR _____________________________________________ 8

PROGRAMMING THE MONITOR _________________________________________ 9

PROGRAMMING THE SENSOR LOCATION _________________________________10

BASELINE PRESSURE PROGRAMMING ____________________________________ 13

PROGRAMMING DATE AND TIME FOR STORED ALARM HISTORY INFORMATION _15

PROGRAMMING THE UNIT OF MEASURE _________________________________ 17

DELETE SENSOR LOCATION ____________________________________________18

HIGH PRESSURE ALARM PROGRAMMING _________________________________ 20

III. INSTALLING THE SENSORS ON THE VEHICLE _______________________21

IV. ALARM MODES ______________________________________________23

VI. NORMAL MODE ACCESSORY FUNCTIONS _________________________26

DROP AND HOOK FEATURE ____________________________________________ 26

SYSTEM RESET ______________________________________________________27

STORED ALARM INFORMATION_________________________________________28

BACKLIGHT ON FOR NIGHT OPERATION __________________________________ 29

VII. FAQs AND TIPS______________________________________________29

FREQUENTLY ASKED QUESTIONS________________________________________ 29

TIPS_______________________________________________________________ 34

LIMITED WARRANTY _________________________________________________ 35

SPECIFICATIONS _____________________________________________________ 36