INSTALLATION, OPERATION AND MAINTENANCE MANUAL

FW cooling only range –Monosplit single-phase

Caution: the use of a manual that is not up to date with the condensing unit version does not

engage the responsibility of LTB

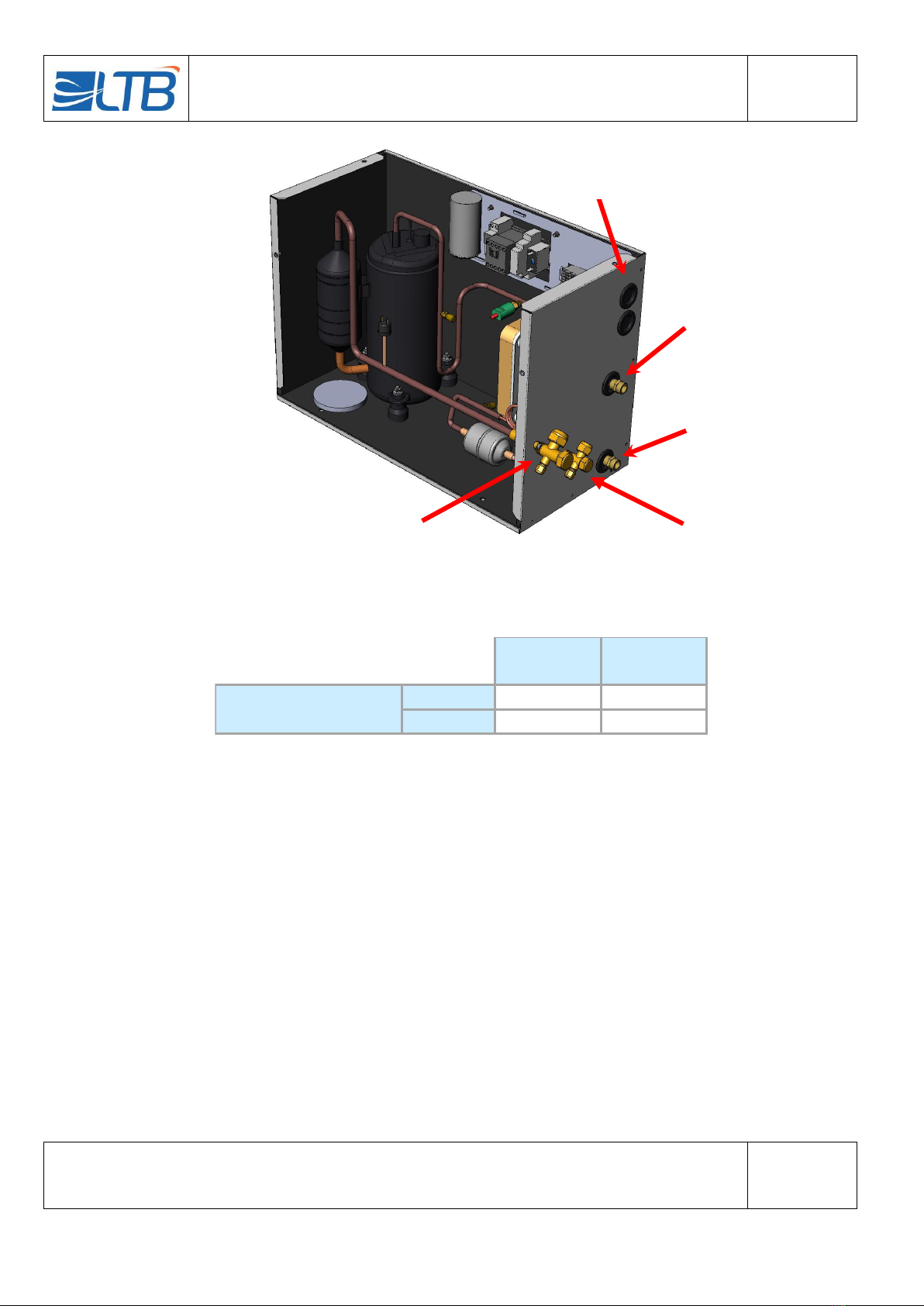

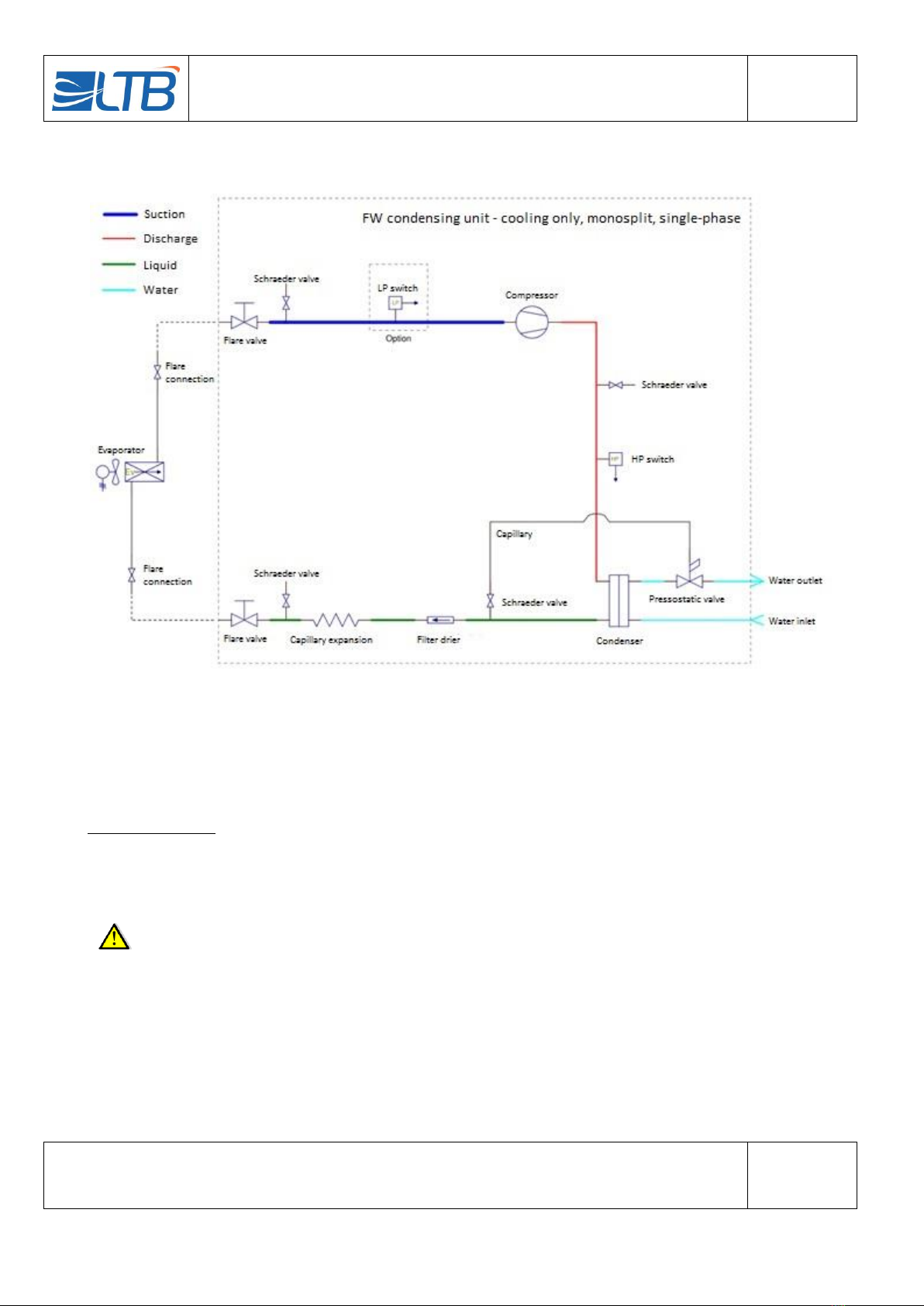

7INSTALLATION : FRIGORIFIC CONNECTIONS

All the usual precautions should be taken when setting up the refrigerant connections. In particular, it is

necessary to limit the number of bends, to make a 2% gradient on the suction line and to make the necessary

oil traps in order to have a good oil circulation. It must also be ensured that the connections are plugged in

order to prevent any impurity or moisture penetration during the installation

The maximum distance between the CU and the IU is 20 linear meters and the maximum height

difference is 5 m. The length of the liquid line as that of the suction line should not exceed 20 meters.

The GI36-40 / 75Pa, GI36-40 / 150Pa and CI36 indoor units do not have the same connection diameter as the

FW36Q6 condensing unit for the suction line. You need to install an adaptation at the CU side. This is

delivered in a separate cardboard box.

The realization of flares for the link on the flare connections should be neat. The presence of burr, crack, a too

small or too large flaring surface may cause leakage.

Flared valves must be kept closed during connection.

The tightening torque for the flared valves are:

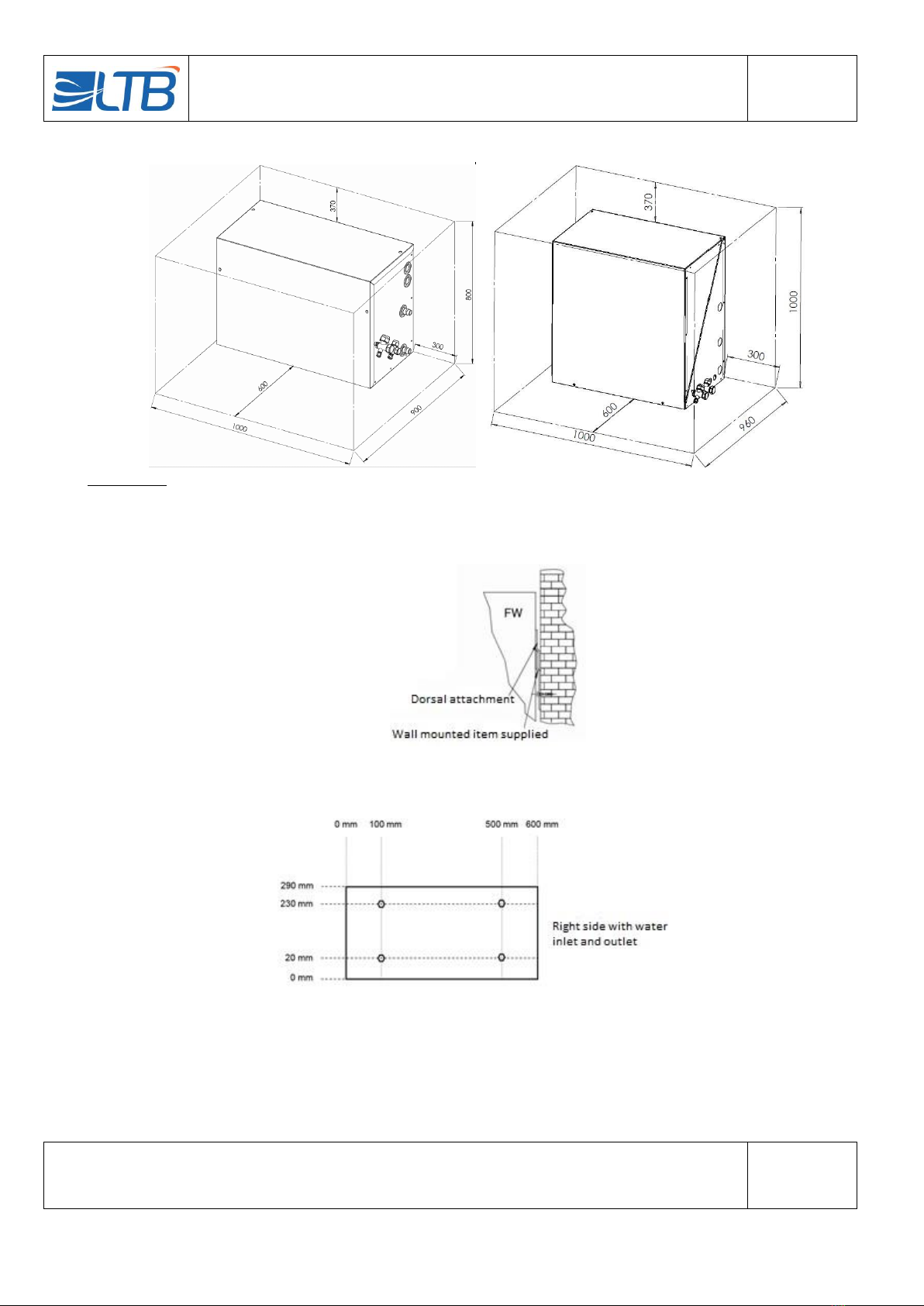

8INSTALLATION : HYDRAULIC CONNECTION

The units are delivered with 2 flexible hoses + washers to be easily connected to the water network.

In order to limit clogging of the plate heat exchanger and optimize CU operation, it is advisable to install a

strainer filter (Ø 0.1mm) on the CU water inlet piping. This filter must remain easily accessible for the operator

so that he can perform a periodical check. A strainer filter performing this function is available as an accessory.

It is delivered separately and to be connected at a workmanlike manner.

All precautions should be taken. In particular, it must be ensured that:

All piping is frost-free

There is no high point where an air pocket could be formed.

The pipes have a sufficient section for the water flow that is to be established.

The available water flow and water pressure are sufficient.

The proper functioning of the CU depends on the good quality of the heat exchange between the refrigerant

and the water to reject calories. The water inlet temperature and the flow rate are essential parameters for the

proper functioning of the installation:

If the water temperature is too high or the flow rate is too low, the power output can be lower than the

rated power.

If the water temperature is too high or the flow rate too low, the CU will get into safety (HP cut).