4

INDICE

1. INTRODUCTION.............................................................................................................................6

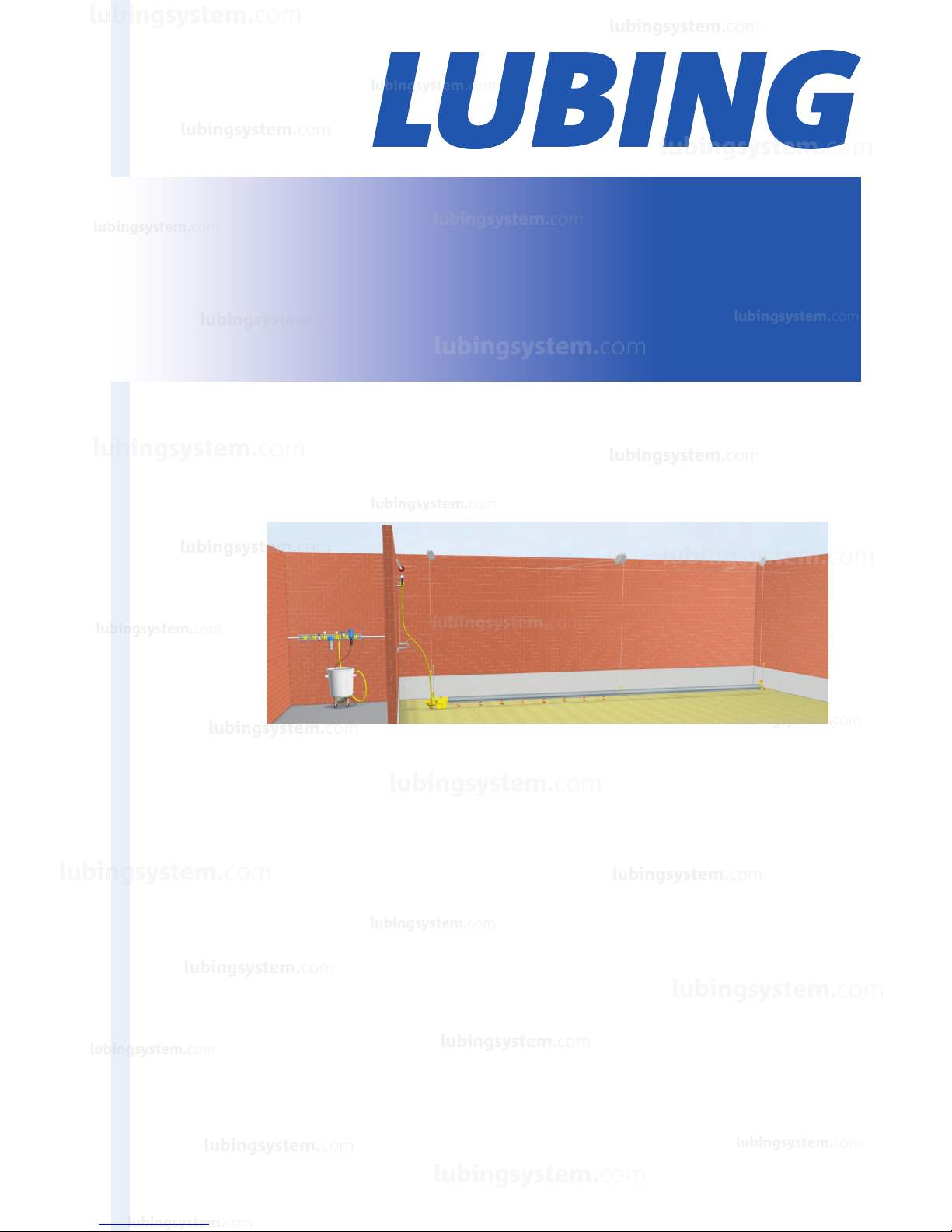

1.1 Brief description of LUBING watering systems for floor watering.................................................6

1.2 Designated use...........................................................................................................................6

2. GENERAL INFORMATION.............................................................................................................6

2.1 Warnings and symbols...............................................................................................................6

2.2 General safety guidelines............................................................................................................7

2.3 Obligations.................................................................................................................................7

2.4 Warranty and liability...................................................................................................................7

2.5 Electrical system.........................................................................................................................7

3. ASSEMBLY.....................................................................................................................................8

3.1 Assembly information.................................................................................................................8

3.2 Assembly order...........................................................................................................................8

3.3 Spare parts.................................................................................................................................8

3.4 Assembly overview.....................................................................................................................8

3.4.1 Principal design of LUBING nipple watering systems...........................................................8

3.4.2 Fitting the main water supply..............................................................................................9

3.4.2.1 Mixer...................................................................................................................10

3.4.2.2 Connection accessories......................................................................................10

3.4.2.3 Fitting the water connection kit............................................................................11

3.4.2.4 Glued connections...............................................................................................11

3.4.3 Fitting the drinking line.....................................................................................................12

3.4.3.1 Mounting the hand winches.................................................................................12

3.4.3.2 Mounting the ceiling winches...............................................................................13

3.4.4 Pressure regulating units..................................................................................................14

3.4.4.1 Pressure regulator................................................................................................14

3.4.5 Connecting of the drinking elements................................................................................16

3.4.6 End piece.........................................................................................................................17

4. OPERATING INSTRUCTIONS.....................................................................................................17

4.1 Arrangement of the nipple drinking lines....................................................................................19

4.2 Before hutching........................................................................................................................19

4.2.1 Cleaning..........................................................................................................................19

4.2.1.1 Cleaning the nipple drinking system of dirt and lime accumulation........................19

4.2.1.2 General cleaning of the drinking systems via medicator........................................20

4.2.1.3 Cleaning the nipple drinking system of algaes and accumulations of medicaments..20

4.2.2 Cleaning of the dosers (if available)...................................................................................22

4.2.3 Cleaning of the water filter................................................................................................22

4.3 Vaccinating via drinking water...................................................................................................22

4.4 Hutching in...............................................................................................................................22

4.5 While rearing............................................................................................................................22

4.6 While finishing..........................................................................................................................22

4.7 Between the circles..................................................................................................................22

4.8 Flushing....................................................................................................................................22

4.9 Height table..............................................................................................................................23

4.10 Resistance to chemicals of the drinker components...............................................................24

4.11 Timer for magnetic valve.........................................................................................................24

4.12 Wiring diagram circulation unit................................................................................................25

4.13 Attendance and maintenance.................................................................................................25