Various types of sewing

Sewing buttonhole

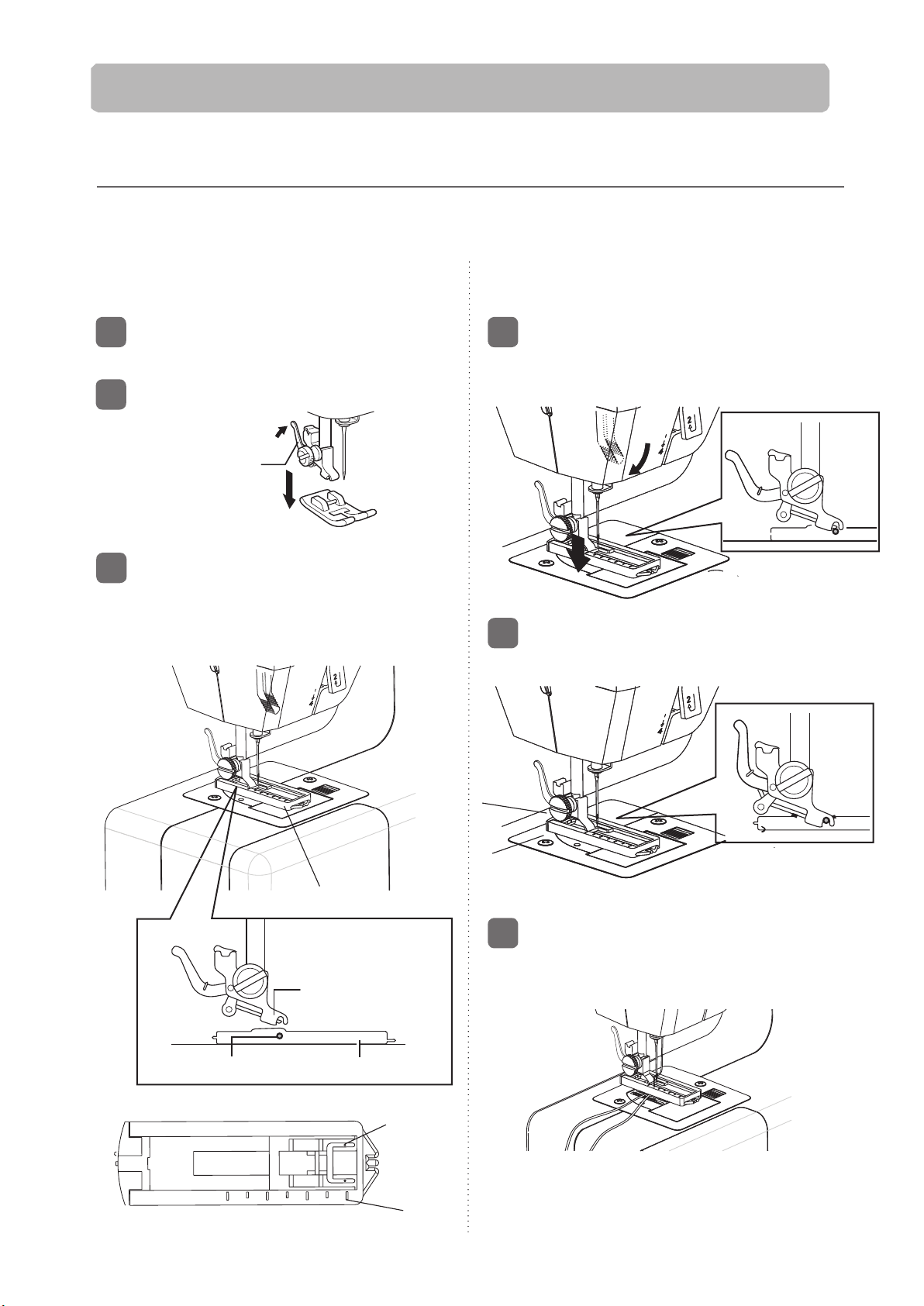

11

2 the fabric beneath the presser foot.

the left .

removable . Move the slider frame toward

3

9

needle thread

bobbin thread

4

5

6

7

8

9

needle is in its high position.

Select Pattern selection dial to “G” to sew right

side bar tack.

Select Pattern selection dial to “H” to sew back

bar tack for 4 or 5 stitches.

Select Pattern selection dial to “I” to sew left side

bar tack until the needle reaches the stitches sew

in step 6.

Select Pattern selection dial to “H” to sew front bar

tack for 4 or 5 stitches.

Pattern

selector

dial

2

4

Your sewing will be neater if

you guide the fabric as it passes

through the machine.

Hints

Caution

Stop the sewing machine and raise the needle and the thread

tension lever to their highest positions when you rotate the pattern

selection dial. Turning the dial while the machine is running

can damage the machine.

Caution

Be careful not to put your hand in front of the seam

ripper. Doing so can result in injury.

Insert a dress pin in front of the bar tacking

and use a standard seam ripper to cut the

buttonhole open.

When you have finished sewing, pull the fabric,

and cut the thread.

To keep the thread from unraveling, pull out the

upper thread from the rear of the fabric and tie

it off with the bobbin thread.

then follow the

steps below in

order indicated

while changing

the stitch

selection dial.

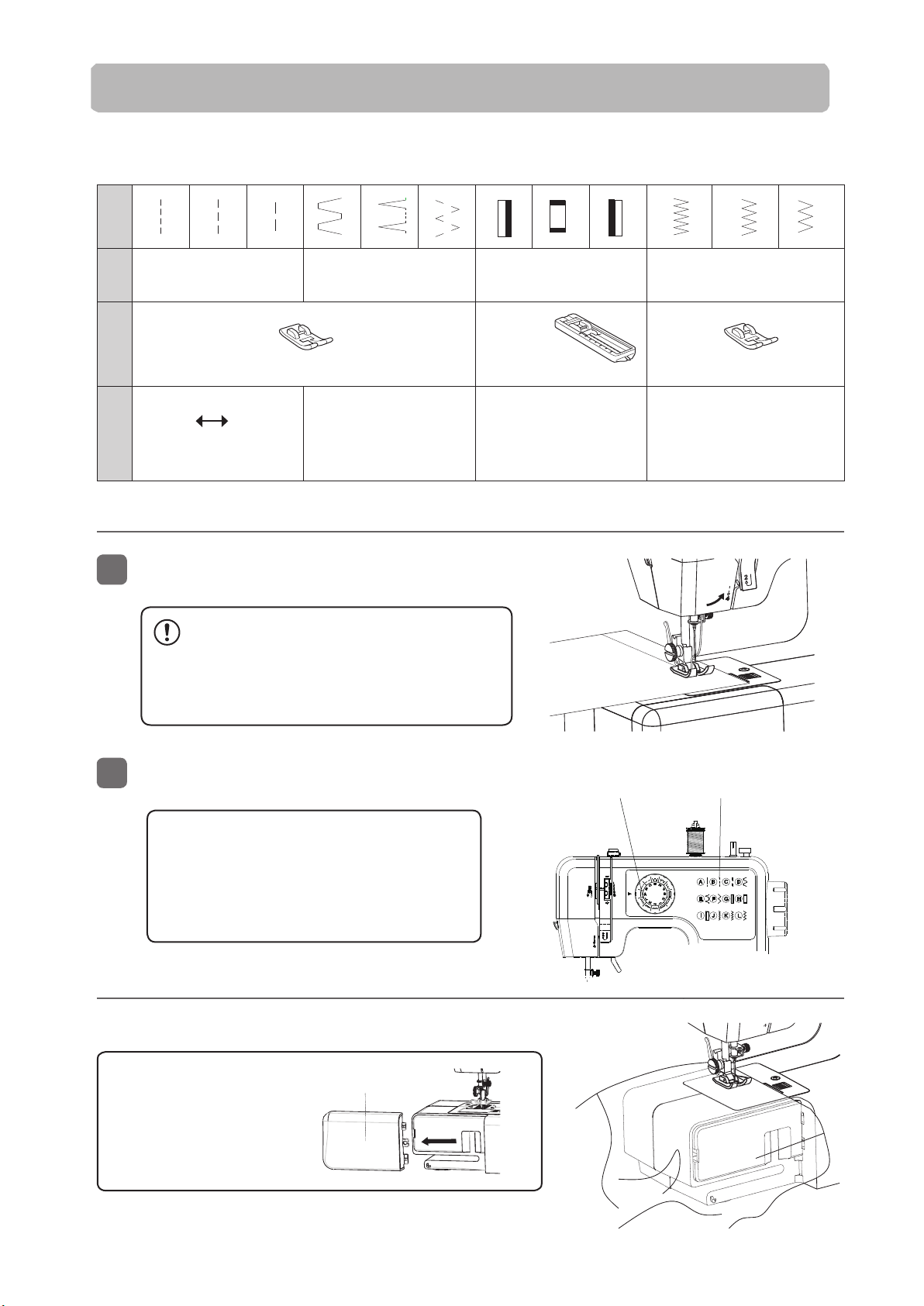

Buttonhole length

( Button diameter +

button thickness)

10

11

2

1

you so that the top mark on the slider meets

the start mark.

Using tailor’s chalk, mark the position

of the buttonhole on the fabric.

Attach the buttonhole presser foot and place

Slider frame of buttonhole is

Draw both of needle and bobbin thread to

Choose the buttonhole length as per your

requirement by stopping slider frame movement.

Please see the following picture.

Lower presser foot lifter and make sure the

7

: end of sewing

78

9

6