Lucznik Laura 555 User manual

USER MANUAL

Important safety instructions

Please read the following instructions before using the machine.

When using an electrical appliance, basic safety precautions should

always be followed, including the following:

1. Read the manual carefully before using the machine.

2. The manual should be kept close to the machine. If the machine is passed on to a third party, it must be

handed over together with the instructions.

3. The machine may only be used in a dry place.

4. Never leave the machine unattended in the presence of children or elderly people, as they may not be

aware of the risks associated with its use.

5. The device may be used by children from 8 years of age and people with reduced physical, sensory or

mental abilities or without experience or knowledge in this field, provided this is done under supervision

or they are instructed to use the device safely and understand the danger associated with it.

6. Children must not play with the machine.

7. Children must not clean or maintain the machine without adult supervision.

8. When preparing for work (changing the needle, threading the thread, changing the presser foot, etc.),

always turn off the machine.

9. Immediately after using the machine or before carrying out maintenance (cleaning and oiling), always

disconnect the machine from the power supply.

10. Do not start the machine if it gets wet.

11. Never pull on the cord. Always hold the plug when disconnecting the machine from the power supply.

12. In the event of damage or failure of the LED lamp, it may only be replaced by an authorized service

center.

13. Never put any objects on the machine's pedal (foot controller).

14. If the ventilation openings are blocked, the machine must not be used. Make sure that neither the

vents nor the pedal are covered with dust, lint, or clippings.

15. The machine may only be used with the regulator included with the machine or purchased at an

authorized service point.

16. The loudness of the correct operation of the machine should be less than 75 dB (A).

SAVE THESE INSTRUCTIONS

Any repairs should be performed by an authorized service center.

This product is intended for home use

SEWING MACHINES

IMPORTER: ASPA Electro Sp. z o. o. ul. Miechowskiego 1, 51-162

Wrocław

tel: +48 71 32 73 138

In case of any problems, please

contact us in writing or by phone:

CENTRAL SERVICE: ASPA Electro Sp. z o. o.

ul. Lubelska 89/95, 26-600 Radom

tel. 048 384 00 13, fax 048 384 00 26

We wish you satisfaction with the use of our products

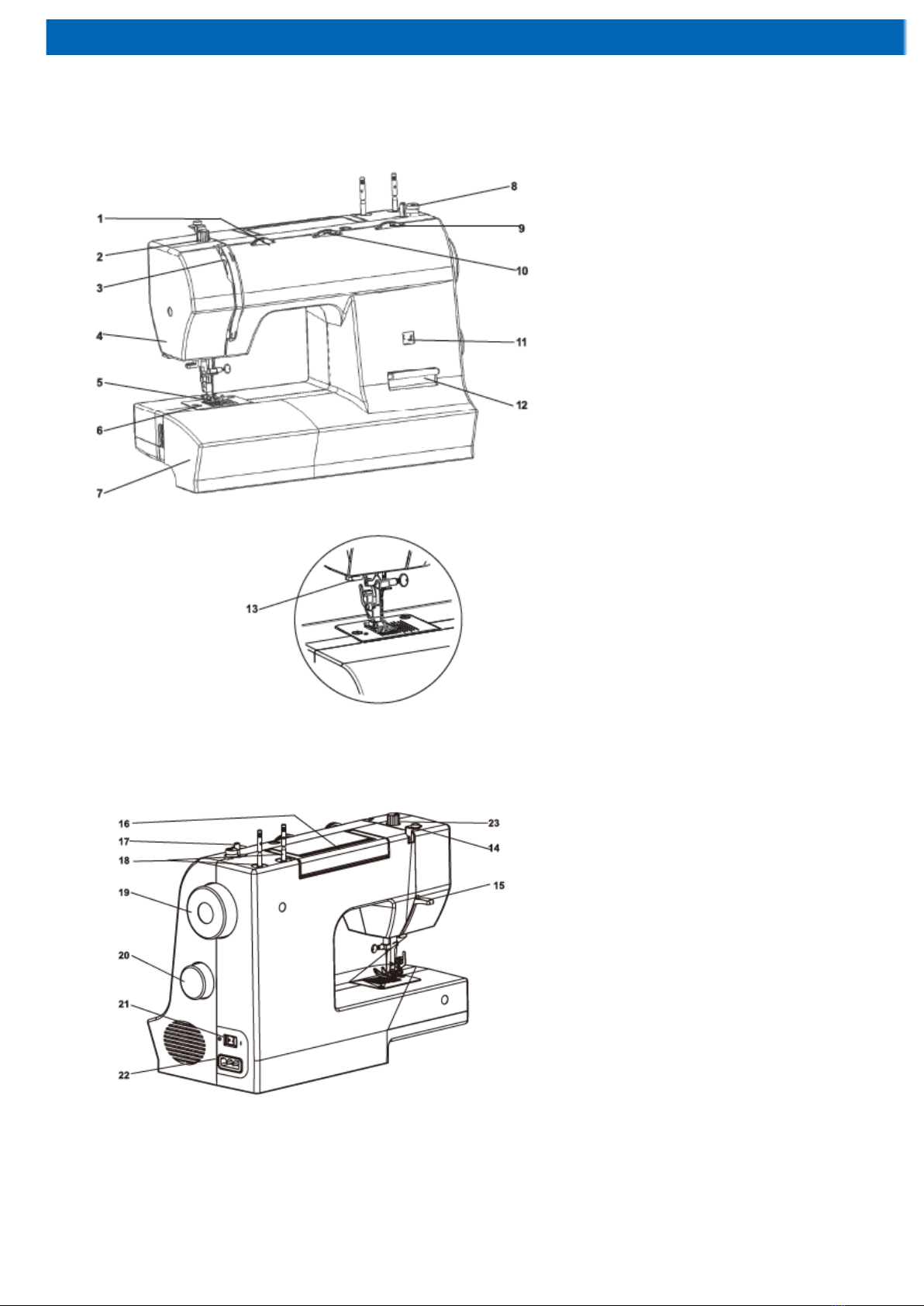

MAIN PARTS

1. Thread tension dial

2. Foot pressure regulator

3. Thread take-up lever

4. Thread cutter

5. Footer

6. Needle plate

7. Sewing table and accessory box

8. Bobbin stopper

9. Stitch length dial

10. Stitch width dial

11. Stitch display

12. Reverse sewing lever

13. Automatic threader (optional)

14. Upper thread guide

15. Presser foot lever

16. Handle

17. Bobbin spindle

18. Thread spindle

19. Handwheel

20. Pattern selection dial

21. Power switch

22. Power socket

23. Bobbin thread guide

ACCESSORIES

Standard accessories 1

a. Universal foot

b. Zipper foot

c. 4-step buttonhole foot

d. Embroidery plate

e. Quilting guide

f. Buttonhole cutter/brush

g. Oil bottle

h. Needles (x3)

i. Bobbins (x3)

j. Screwdriver (small)

k. Screwdriver (large)

l. Screwdriver (L)

Optional equipment 2

m. Foot for sewing buttons

n. Blind stitch foot

o. Double needle

p. Darning foot

q. Shirring foot

r. Foot for sewing in string

s. Walking foot

t. Darning / hemming foot

u. Quilting foot

v. Quilting guide

Hold the snap-in sewing table horizontal, and

push it in the direction of the arrow (1)

The inside of the snap-in sewing table can be

utilized as an accessory box.

To open, lift up at the point of the arrow (2)

FITTING THE SPAN-IN SEWING TABLE

Caution:

Always make sure that the machine is unplugged from the power source and the main switch

is on „O” when the machine is not in use and before inserting or removing parts.

This machine is equipped with a polarized plug which must be used with an appropriate

electrical outlet.

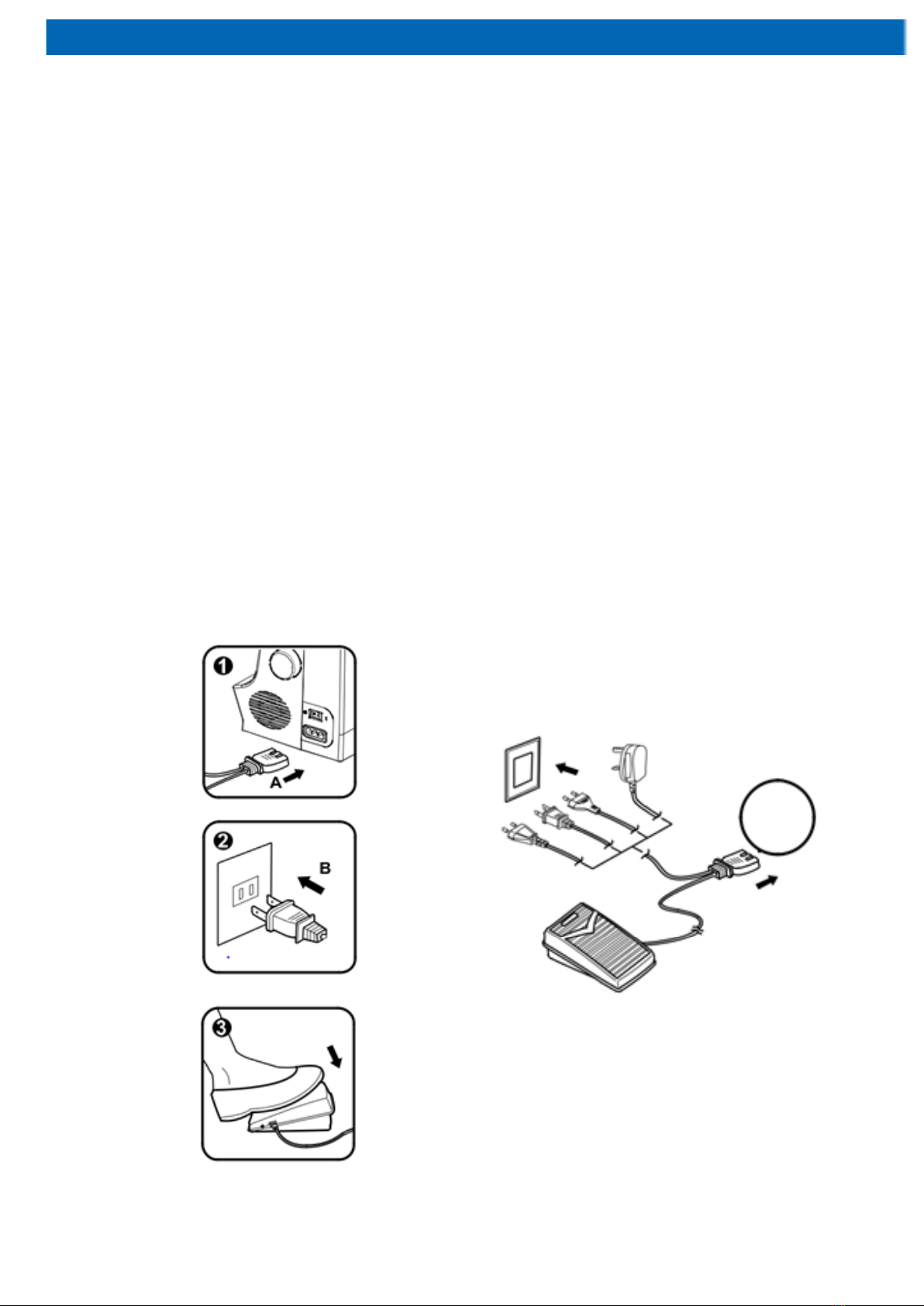

Connect the machine to a power source as illustrated. The power switch is located above the

terminal box. Your machine will not operate unless the switch is on “I”.

The sewing light turns on automatically when the main switch is on “I”.

To start the machine, press the foot control. The speed of the machine is regulated by the

amount of pressure exerted on the foot control.

Attention:

Consult a qualified electrician if in doubt as to connect the machine to the power source.

Unplug the power cord when the machine is not in use.

CONNECTING THE SEWING MACHINE TO THE POWER SOURCE

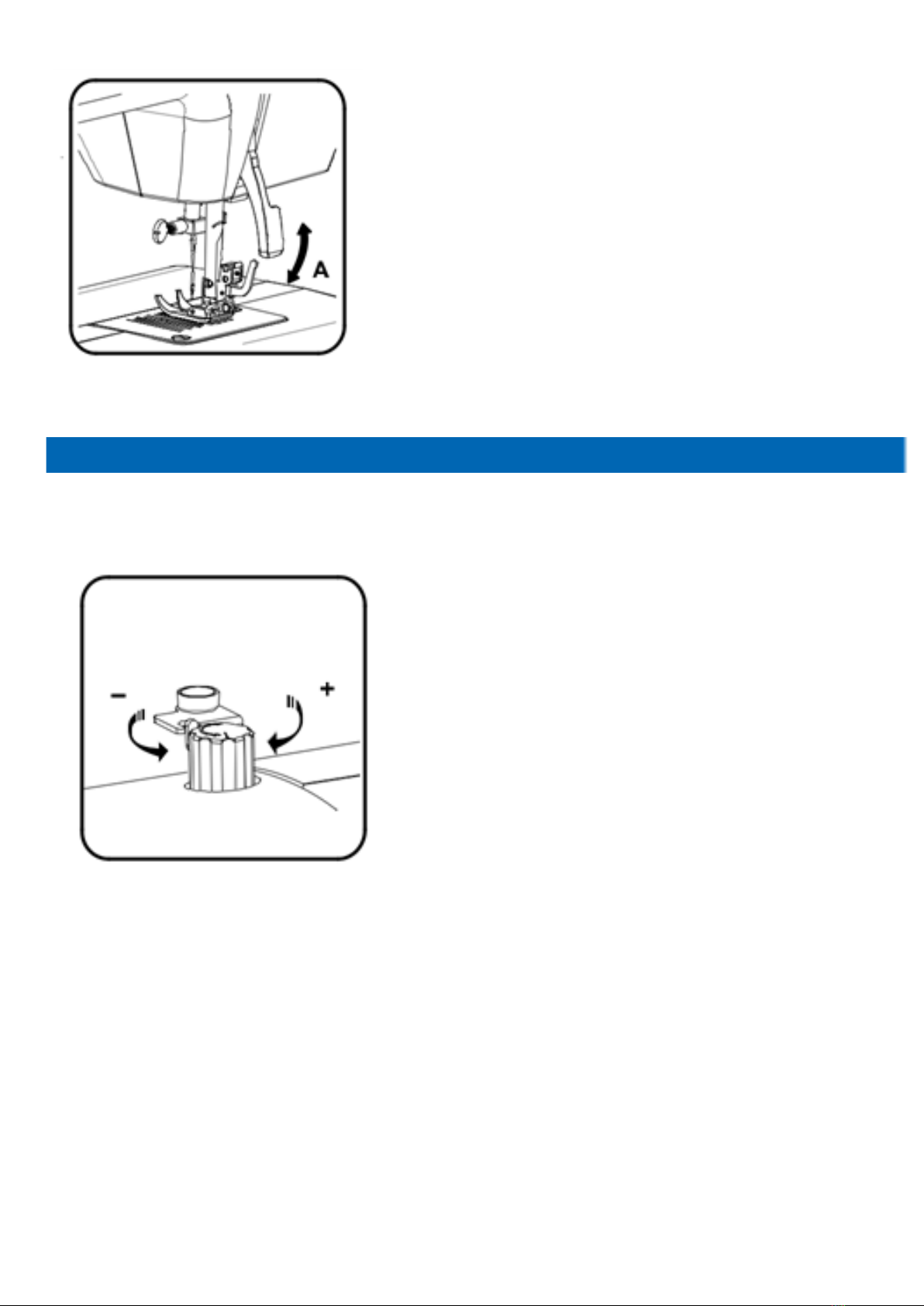

When sewing several layers or thick fabrics, the

presser foot can be raised to the second pressure

level, which makes it easier to work.

ADJUSTMENT OF THE FOOT PRESSURE

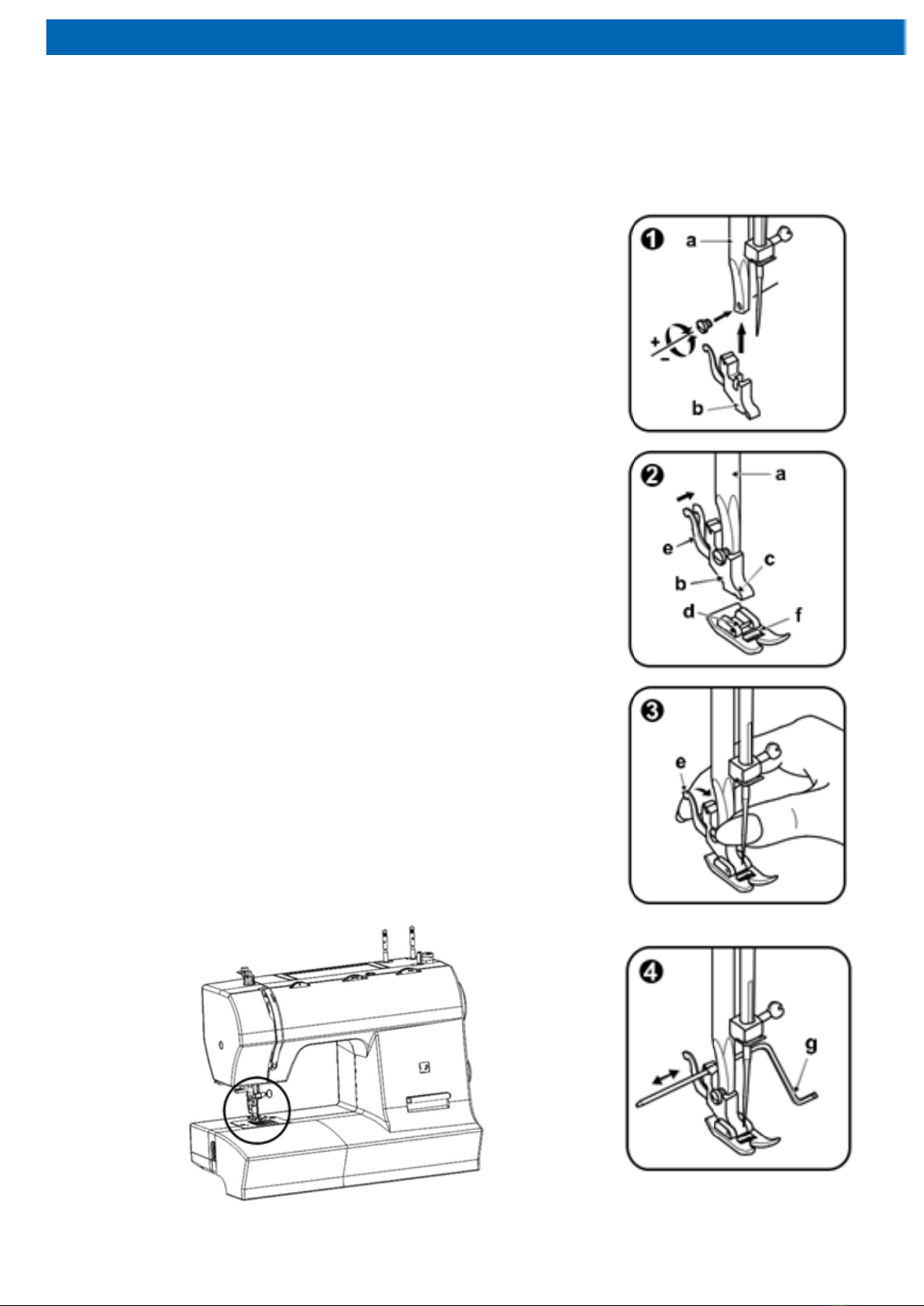

The presser foot pressure is factory set and does

not require special adjustment for a specific type of

fabric (light or heavier).

However, if necessary, you can adjust the presser

foot pressure by turning the presser foot pressure

adjuster as shown in the image on the left.

When sewing with very thin fabrics, reduce the

pressure by turning the regulator counterclockwise,

and for heavy and thick fabrics - increase the

pressure by turning the regulator clockwise

Attention:

Turn the power switch to “O” before carrying out any of the operations below.

ATTACHING THE PRESSER FOOT HOLDER

Raise the needle to its highest position and raise

the presser foot lever. Attach the presser foot

holder (b) to the presser foot bar (a) Pic.1

Attaching the presser foot:

Lower the presser foot holder (b) until the cut-out

(c) is directly above the pin (d) Pic.2

Lower the presser foot holder (b) and the presser

foot (f) will engage automatically.

Removing the presser foot:

Raise the presser foot.

Release the pressure foot by raising lever (e)

located at the back of the foot holder. Pic 3.

Attaching the seam guide:

Attach the seam guide (g) in the slot as illustrated.

Adjust the distance as required for herms, pleats,

etc. Pic. 4

Place an empty bobbin on the bobbin winder spindle.

Take the thread from the spool through the bobbin winder tension disc. (1)

Wind the thread a few times by hand around the empty bobbin in a clockwise direction. Push

the bobbin to the right towards the bobbin winding position. (2)

Press the foot control gently. The bobbin will stop winding when it is full. Push the bobbin to

the left to “sewing position” and remove it.

Please Note:

When the bobbin winder spindle is in “bobbin winding” position, the machine will not sew and

the handwheel will not turn. To start sewing, push the bobbin winder spindle to the left

(sewing position).

WINDING THE BOBBIN

Table of contents

Other Lucznik Sewing Machine manuals