3

Contents

1. How to use this manual......................................................................................................................5

1.1 Validity............................................................................................................................................................5

1.2 Target Group..................................................................................................................................................5

1.3 SW version ....................................................................................................................................................5

1.4 Documentation and declaration of conformity ...............................................................................................5

2. Safety Precautions..............................................................................................................................7

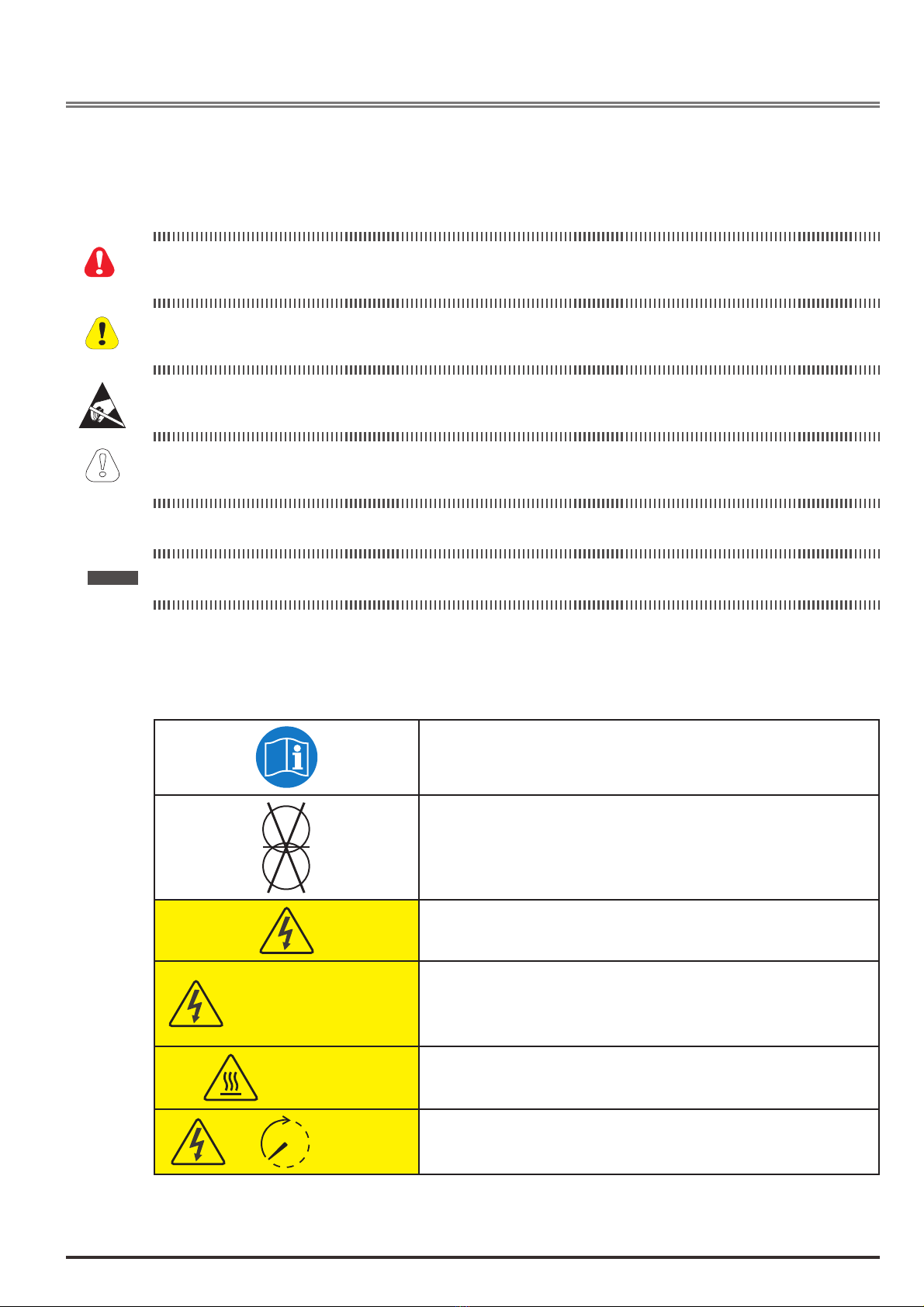

2.1 Symbols used in the manual..........................................................................................................................7

2.2 Symbols used on outside labels ...................................................................................................................7

2.3 General warnings and safety information ......................................................................................................8

2.4 Intended or permitted purpose ......................................................................................................................9

2.5 Improper or prohibited use ............................................................................................................................9

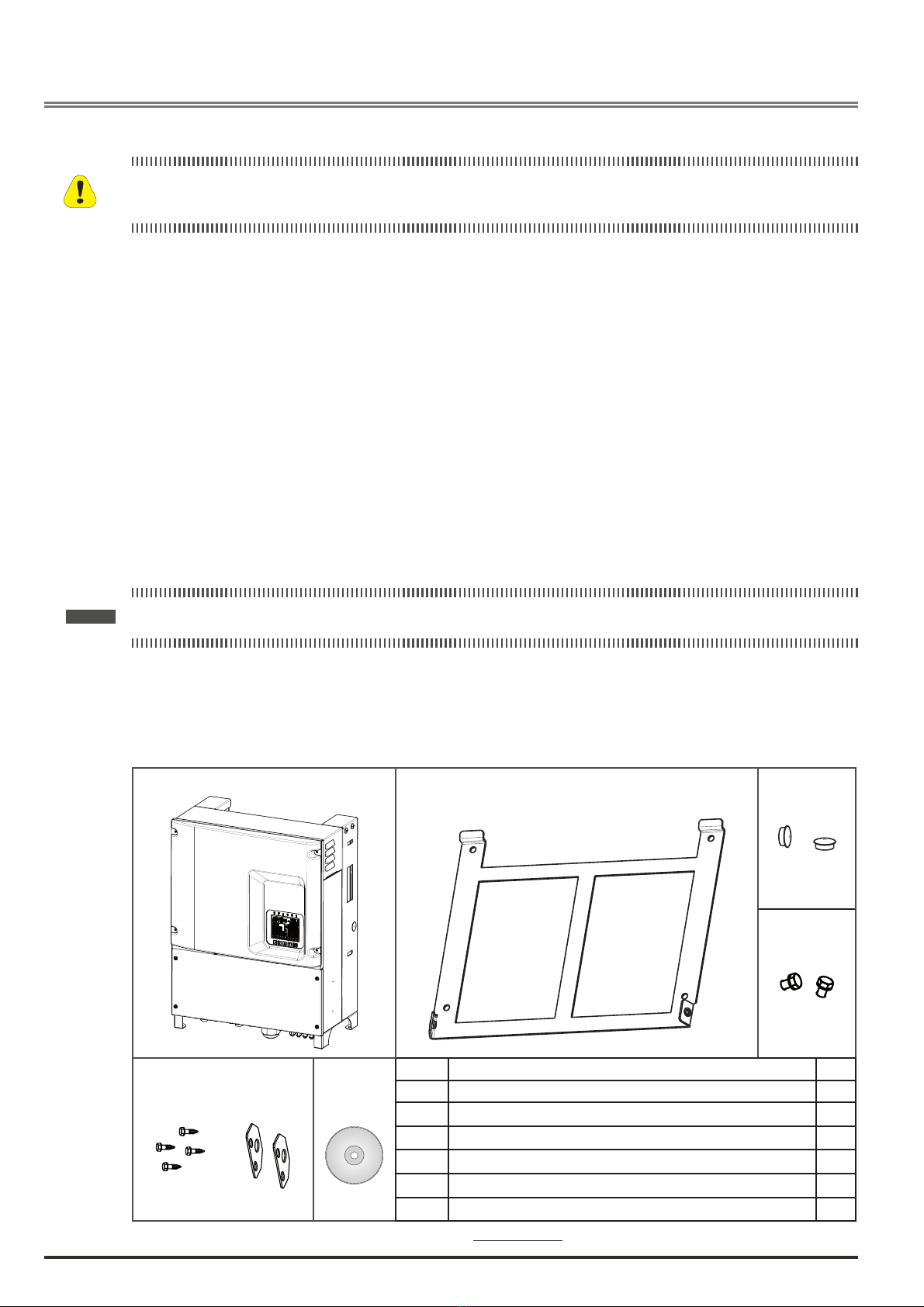

3. Transportation – Handling - Storage...............................................................................................10

3.1 Handling packed equipment ........................................................................................................................10

3.2 Packaging and unpacking............................................................................................................................10

3.3 Storage ........................................................................................................................................................ 11

3.4 Handling the equipment after unpacking .....................................................................................................12

3.5 Disposal of the device..................................................................................................................................13

4. Description of the RADIUS PVSA inverter......................................................................................14

4.1 Introduction ..................................................................................................................................................14

4.2 Block diagrams PVSA..................................................................................................................................15

4.3 Installation notes..........................................................................................................................................15

4.4 Device identi!cation.....................................................................................................................................16

4.4.1 Data plate..................................................................................................................................................................16

4.4.2 Model identi!cation (Type) ........................................................................................................................................16

5. Installation .........................................................................................................................................17

5.1 Safety instructions .......................................................................................................................................17

5.2 Selecting the Installation site .......................................................................................................................17

5.3 Mounting ......................................................................................................................................................18

5.3.1 Mounting the device on a wall...................................................................................................................................18

5.3.2 Mounting the inverter on the bracket.........................................................................................................................19

6. Electrical Connection .......................................................................................................................20

6.1 System Diagram with Inverter and Electrical connection.............................................................................20

6.2 Safety...........................................................................................................................................................20

6.3 Removal of the lower panel .........................................................................................................................21

6.4 Connecting to the grid (utility grid) and ground cable (PE) ..........................................................................21

6.4.1 Connecting to the PV panel (DC input) .....................................................................................................................23

6.4.2 Connection PVSA-AE-... models...............................................................................................................................24

6.4.3 Connection PVSA-EE-... models...............................................................................................................................26

6.5 Removing the backup battery protection .....................................................................................................27

6.6 Fixing of the lower panel..............................................................................................................................28

6.7 DC side fuses and string current monitoring................................................................................................29

6.7.1 DC side fuses (integrated inside -F models) .............................................................................................................29

6.7.2 String current monitoring...........................................................................................................................................30

6.8 GROUND KIT ..............................................................................................................................................31

6.9 AC side fuses...............................................................................................................................................32

6.10 Choice of leakage breaker on AC side .......................................................................................................32

6.11 DC circuit breaker ........................................................................................................................................33

6.12 Other connections........................................................................................................................................34

6.12.1 Inputs / Outputs regulation circuit..............................................................................................................................35

6.12.2 Communication .........................................................................................................................................................38

6.12.3 USB functions use.....................................................................................................................................................39

7. Display and Functionality ...............................................................................................................41

7.1 KA Display ...................................................................................................................................................41

7.2 Display KB ...................................................................................................................................................41

7.3 Meaning of LEDs .........................................................................................................................................42

7.3.1 Inverter status: initialization procedure......................................................................................................................42

7.3.2 Inverter status: DC-Grid Connection phase ..............................................................................................................42

7.3.3 Inverter status: Grid Connected ................................................................................................................................42

7.3.4 Inverter status: Generation Ramp .............................................................................................................................42

7.3.5 Inverter status: Generation........................................................................................................................................42

7.3.6 Inverter status: Special Function / Power Limitation .................................................................................................43

7.3.7 Inverter status: Fault ................................................................................................................................................43

7.3.8 Inverter status: Warning ...........................................................................................................................................43

7.4 Meaning and function of keys ......................................................................................................................43

7.5 Commissioning ...........................................................................................................................................44