5

1. APPLICATION

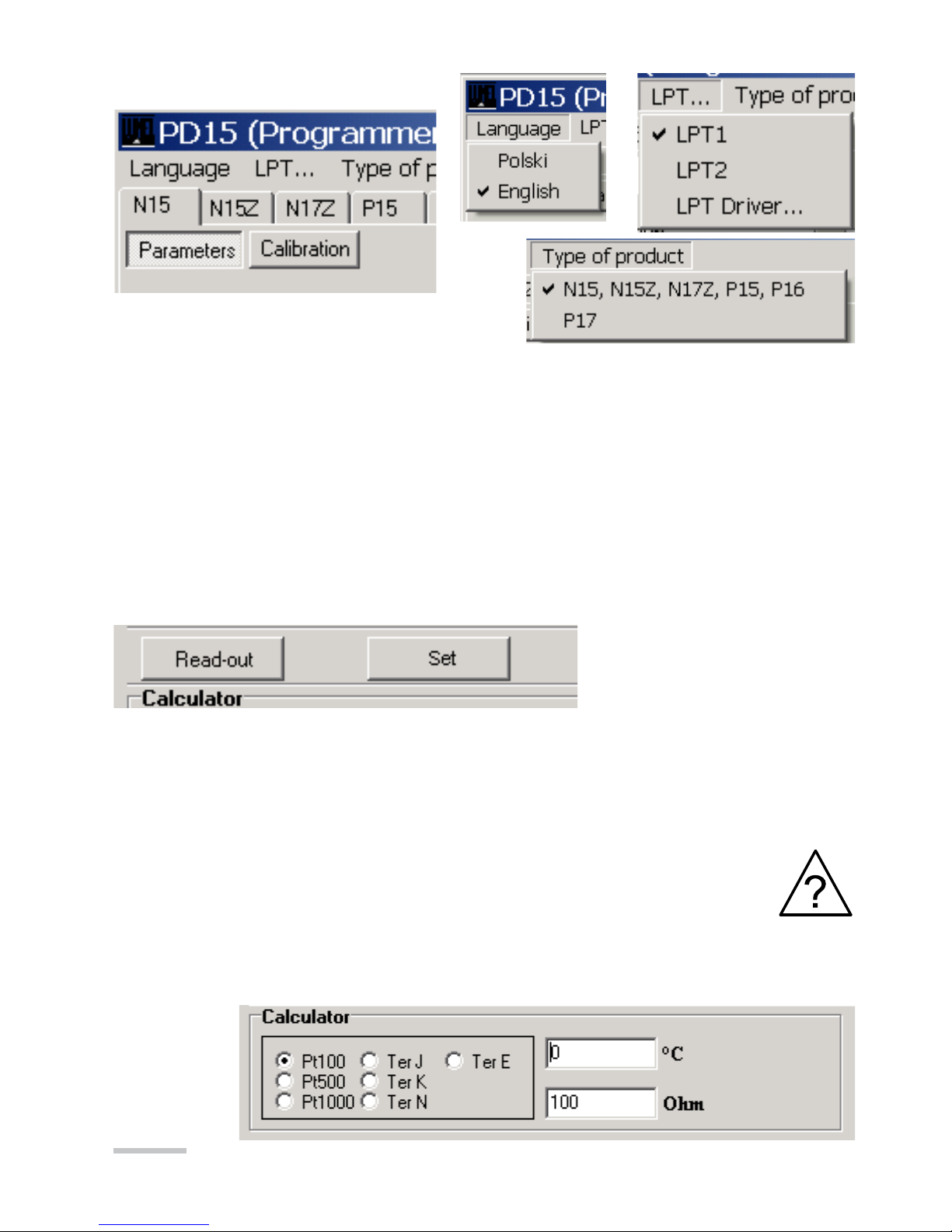

The PD15 programmer is destined to program meters of N15 , N15Z, N17Z digital

meter series, P15 and P16 transducers in the windows 9x/2000/NT/XP environ-

ment.

The programmer enables:

zmianê parametrów mierników i przetworników,

kalibracjê mierników i przetworników.

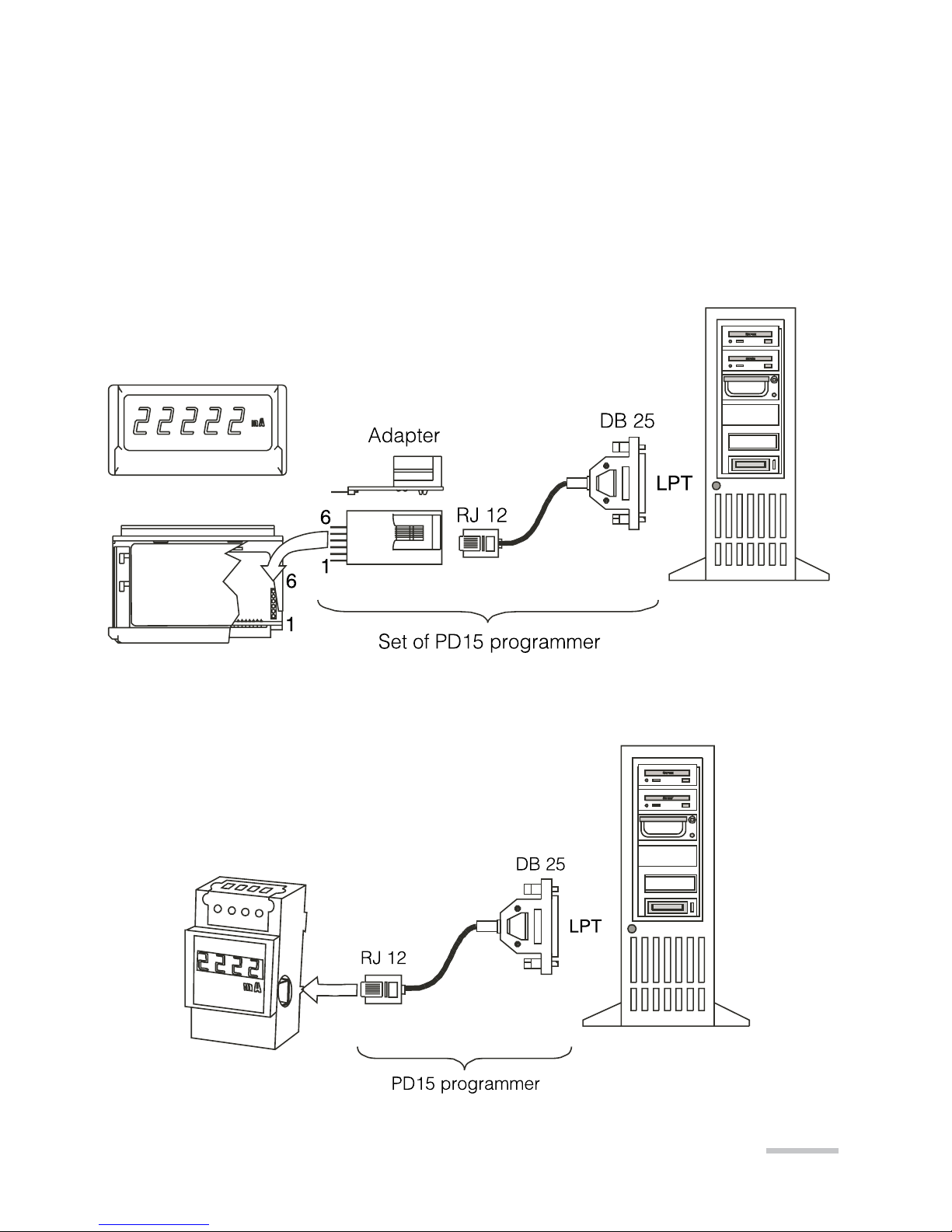

2. PROGRAMMER SET

The PD15 programmer set is composed of:

- PD15 programmer 1 pc

- Mini CD Diskette with software 1 pc

- Adapter plate 1 pc

- User’s manual 1 pc

- Guarantee card 1 pc

When unpacking the programmer, please check whether the type and execution

code on the plate correspond to the order code.

3. REQUIREMENTS

- Windows 9x/2000/NT/XP

- Ca 2 MB of empty place on the disk

- Minimum 4 MB RAM memory

- LPT port with the possibility of working in the SPP, EPP or EPP/ECP mode

4. OPERATIONAL SAFETY

Symbols included in this user’s manual mean:

- Particularly important, one must acquaint with it before connecting the

programmer. The non-observation of remarks determined by this symbol

can cause the programmer or meter damage.

- One must take into consideration when the programmer is working

inconsistently with expectations.

Remarks related to the safety:

- The meter reprogramming should be carried out only by an authorised and quali-

fied personnel.

- Before the meter reprogramming one must check the correctness of the program-

mer connection with the meter.

- During the meter reprogramming one must remember about the high voltage being

on the meter power pack elements. Please observe particular caution. Possible

consequence if disregarded.