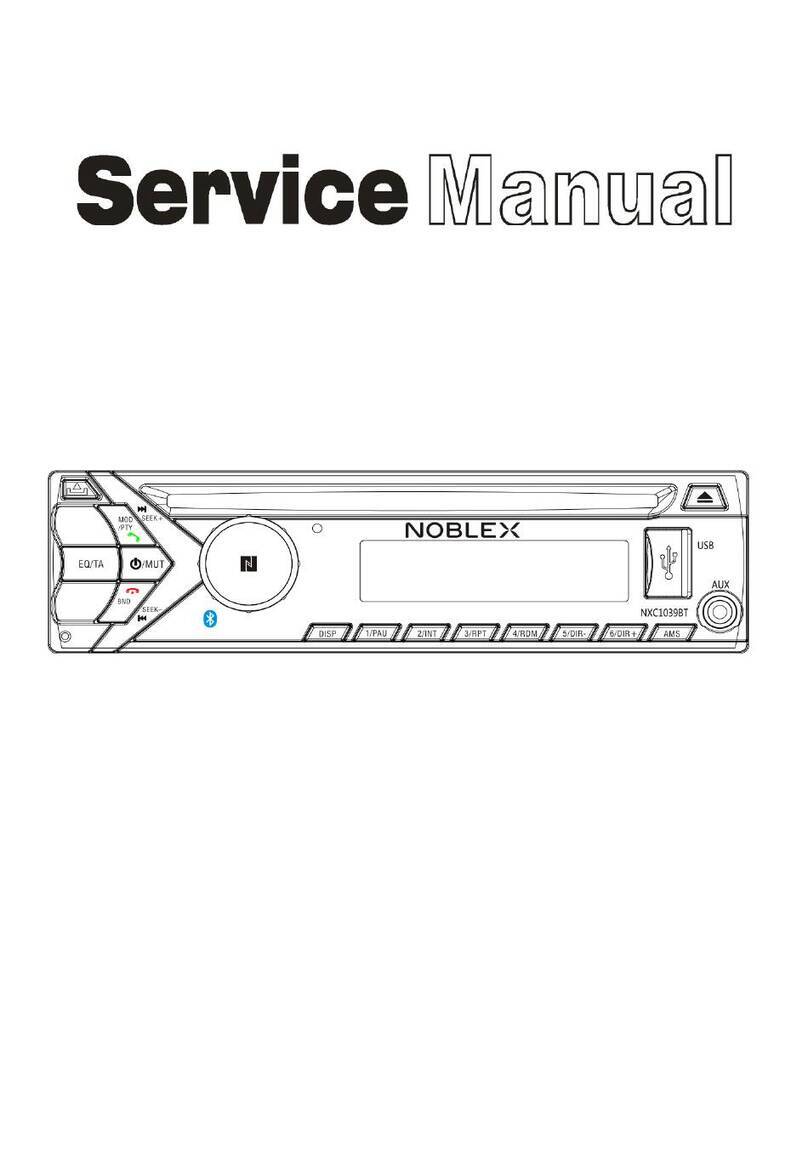

D-375

CONTENTS

FULL-AUTO

MECHA.

TIMING

CHART...

cecscrseccccccncces

EXPLANATION

ABOUT

FULL-AUTO

MECHANISM.

...secceeescee

PB-1373

BLOCK

DIAGRAM.

cccccvccccsvccnccccccceces

aioe

EXPLANATION

ABOUT

TRANSISTOR'S...cccccccccencccssece

MUTING

CIRCUIT

(CANCEL

CIRCUIT).

..ccccccccccccsvoves

MUTING

CIRCUIT

TIMING

CHART...

ccccccccccscccceevecces

PB-1373

TIMING

CHART.

ccccccsccccscccnvccesscccence

PB-1373

CIRCUIT

DIAGRAM.

.cccccccccccvnecs

ovcccescces

MOTOR

SWITCH

CIRCUIT.

.ccccccccnccccccccccccenccscecs

FULL-AUTO

MECHANISM

ALIGNMENT

PROCEDURES.

..sceeceees

FULL-AUTO

MECHANISM

CIRCUIT

ALIGNMENT

ROCEDURES.

....

P.C.B.

ALIGNMENT

PROCEDURES...

.ccccccccccvecacesces

ADJUSTMENT

OF

SW-O7(MAIN

CAM

SW).....

so

ceccecces

coe

PB-1373-1

PARTS

LIST.

ccc

ccceeccevees

ec

ccewcccescces

8

PB-1373-2

PARTS

LIST.

cccecccceces

ccc

ccesces

ooeccces

8

PB-1373-4

PARTS

LIST.

.ccccccccceccccccccees

oocecces

8

FULL-AUTO

MECHA. P.C.B.

PARTS

LIST.

..cccccccccccceeed

PD-375

EXPLODED

VIEN...ccccccccccccccscnccccescceseed

EXPLODED

VIEW

PARTS

LIST.

.ccccccccccvcccccvccescesced

SCHEMATIC

DIAGRAM.

coccecceeccccccecvccccccecsseeeee

ell

°

°

NN

WO

Ww

fF

fF

FW

WwW

N

DH

FF

SPECIFICATIONS

FULL

AUTO

MECHA,

CIRCUIT

TIMING

CHART

33

r.p.m.

45

r.pm.

AC

Motor

Start

‘AC

Motor

Start

OFF

or

Cut

Record

End

OFF

or

Cut

Record

End

42V

Terminal

No.4

|

0

IC

Pin1,2

__

[|

Tie

Wed

ale

si

“aeaweee

LT

BY

IC

Pin

4

[|

an

toPin8

J.

JO

i.

EME

a

IC

Pin

10

|_|

Vee

| |

cs

IC

Pin12

pu

IC

Pin

13

a

oon

fade

a

Pint

—

~~

-

fo

=

i

SW10

Common

|

|

a

42

|

TRO

—

fo

—

=]

-

F.A.M,

AC

Moter

|

=