9

located on the CD provided. On older operating systems, the user has to

initiate the installation of the driver:

3.2.2.1 Navigate to the Start>Settings>Control Panel>Add New Hardware

3.2.2.2 Follow the instructions on the screen

3.2.2.3 Insert the Luzchem CD, and the operating system will find and install

the appropriate driver

3.2.2.4 To install the application follow the directions in part a.

3.3 Starting the software

To start the spectroradiometer application, double click the shortcut on the desktop, or

the actual application in the Program Files folder. Please note that the application is

only compatible with the spectrometers sold by Luzchem. If the software does not

recognize the spectrometer, it will give an error message and close.

3.4 Optimize Integration Time

The optimize integration time function tests the intensity of the light and searches for

an appropriate integration time. This function is important because if the integration

time is too short, the data is susceptible to errors introduced by noise. If the

integration time is too long, the spectrometer can saturate, and the data above the

saturation point will be a flat line. The spectrometer saturation level is 4000 counts.

3.4.1 Navigate to the “Start Optimize Integration” tab

3.4.2 Press the “Start Optimize” button

3.4.3 Turn on the light and press “Go”. Note that the optimize function does not

require a dark measurement.

3.4.4 The application will test different integration times in order to find the best

one. Once the optimization is done, a dialog box will inform the user of

the optimized integration time. If the integration time is less than 10 or

greater than 1000, a warning message will appear. Please note that the

threshold for the spectrometer is 10 ms. An integration time lower than 10

ms will result in inaccurate readings.

3.4.5 If the optimized integration time falls in an acceptable range, all

integration times in the program will be set to this value. If the optimized

integration time is less than 10, the integration times will remain the same,

and if it is greater than 1000, the integration times will be set to 1000. The

user can override these values.

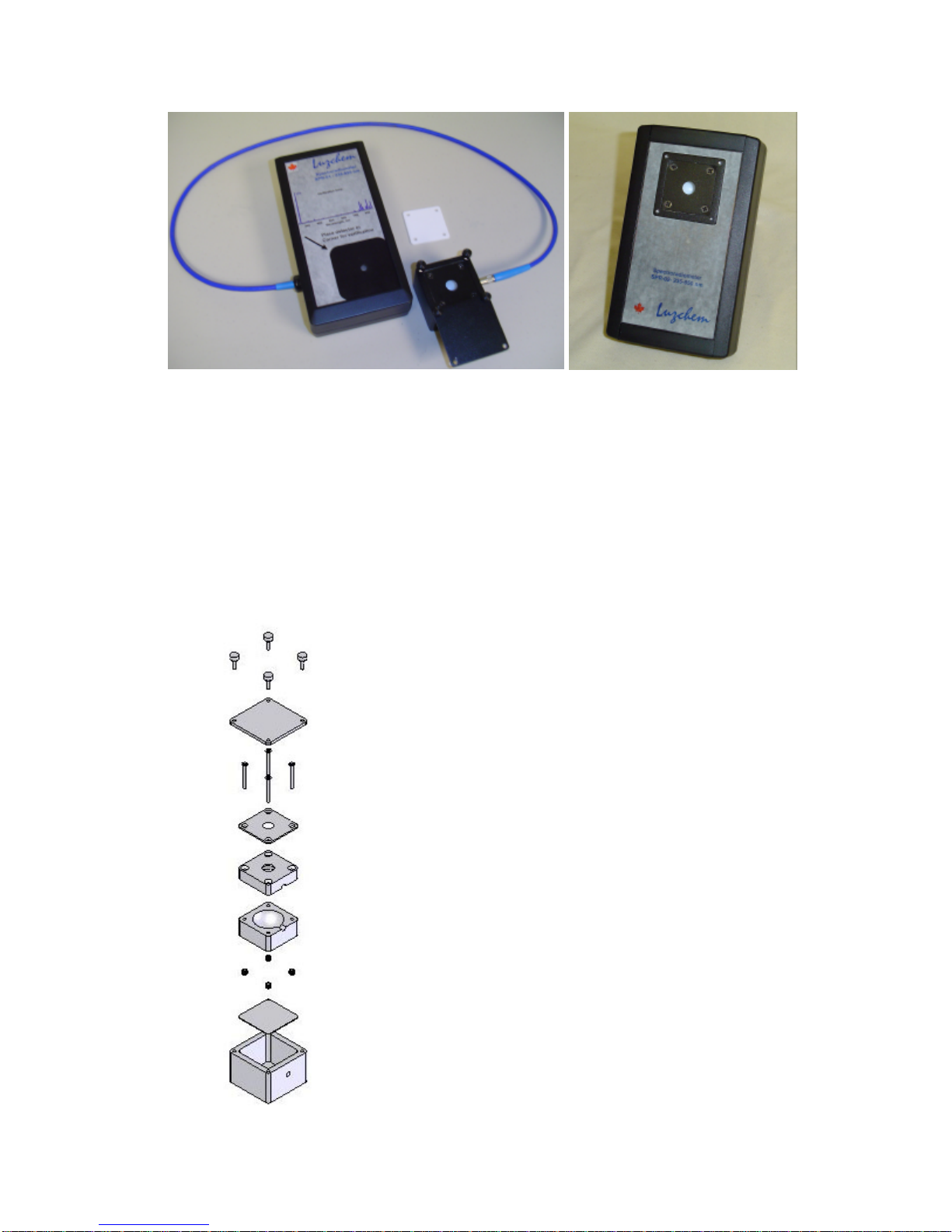

3.4.6 If the signal saturates at 10 ms integration time the use of an attenuator is

highly recommended (See section 2.4).