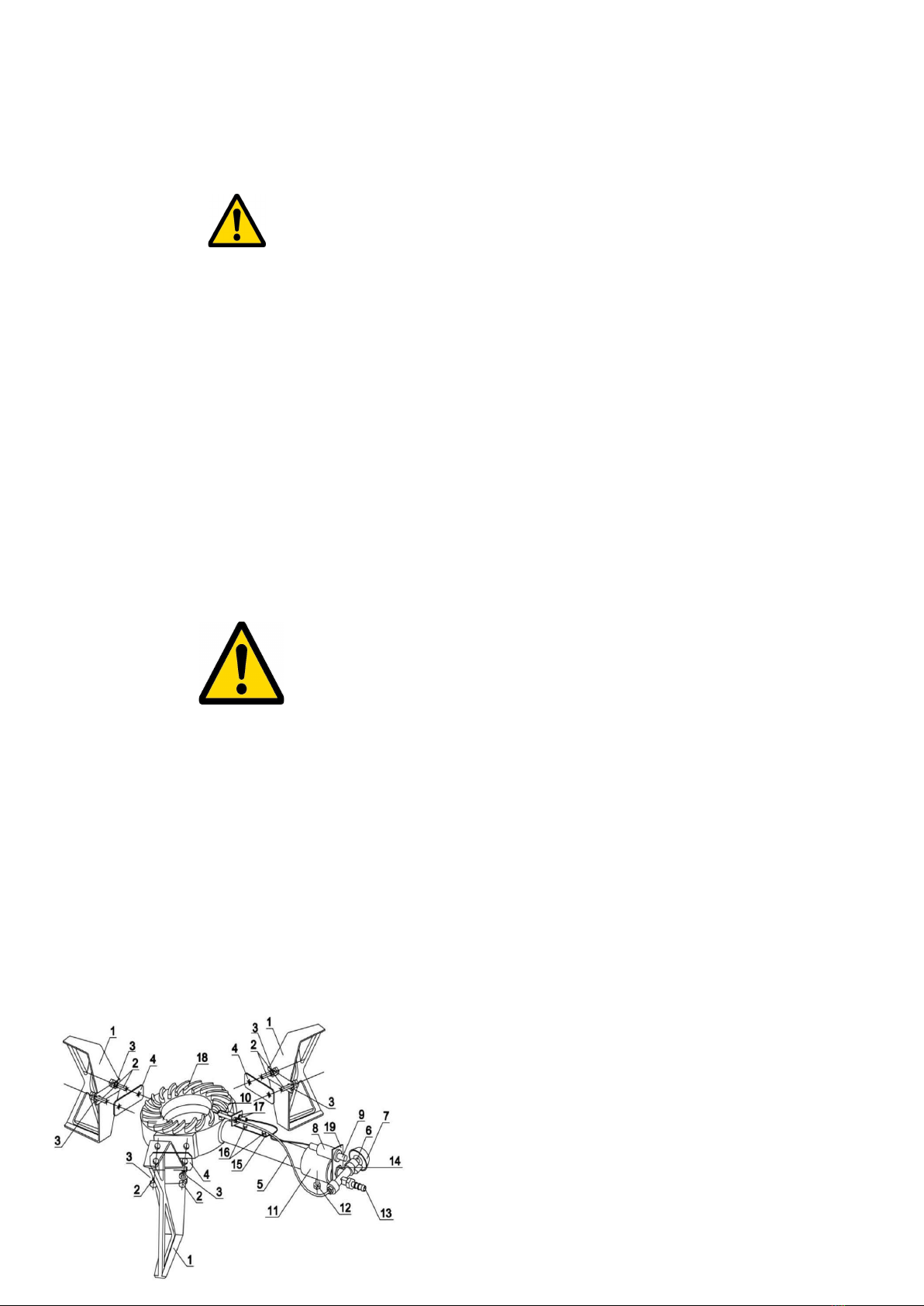

1.Loosen the lock screw (pos. 1) slightly.

2.Slowly move the clamp (pos. 2), and adjust the primary

air supply so that an optimal blue flame is obtained

(yellow or red indicates wrong setting).

3 Slowly tighten the lock screw (pos. 1).

4. after each replacement of the gas cylinder, the

adjustment of the primary air supply should be carried

out again.

Properly performed adjustment should ensure:

fast and correct burner ignition, re-ignition and flame

transmission gentle, explosion-free flame spread on all

flame openings in no more than 5 seconds,

slight flame recoil is allowed, however after 1 minute the

flame shall be stable, the flame does not go out and does

not withdraw towards the nozzle when the burner's heat

output is changed within the entire range of power

adjustment foreseen and when rotating the control knob

from maximum to minimum power at normal speed

(normal speed, i.e. rotating the control knob from

maximum to minimum power for approximately 1 s).

WARNING! Always clean the appliance after use Before

cleaning, make sure that the stove has cooled down -

there is a high risk of burns. Shut off the gas supply to

the appliance by turning off the valves. If you intend to

turn the appliance during cleaning, it is necessary to

disconnect the gas supply hose to the appliance.

(A). Turn off the appliance and disconnect the gas supply

hose before carrying out maintenance.

(B). Make sure the appliance has cooled down.

(C). To prevent damage to the appliance surface, clean it

regularly.

(D). Fat or food residues in the appliance may cause a

fire.

(E). Clean the appliance with a damp cloth.

(F). Use only neutral cleaning agents. Never use

abrasive agents, agents containing caustic, bleaching

substances or acids to clean the stove and avoid using

acidic or alkaline substances (lemon juice, vinegar, etc.).

(G). Do not clean the appliance with steam cleaners.

(H). After cleaning, the appliance must be dried.

3. Periodical service

After the warranty period, the appliance should be

subjected to periodic inspection at least once a year.

The periodic inspection should be carried out by persons

qualified in gas equipment repair and maintenance.

The minimum scope of the periodic inspection is control

of proper operation, maintenance of gas valves and gas

tightness test of the appliance.

Periodic inspections after the warranty period are not

included in the purchase cost of the appliance.

Properly prepared burner with reducer to be connected

to to the cylinder.

7 kW stove for: W4076, W40760, W4072, W4072_O

6,4 kW stove for: W4075

4. Melter operation principles

1. Fill the tank with water up to the level of the drain

pipe as in the picture (Fig.1). Fill in the water (take

special care not to burn yourself).

2. Fill the basket with frames or dry wax material.

3. Cover the device with the lid.

4. Place the stove under the unit so that the flame

heats the entire surface of the bottom of the unit.

5. Wait for the steam to rise and for the melted wax to

flow out.

6. When the wax has been melted check the water

level and top up if necessary.

7. Fill the basket with frames or dry wax material again.

8. Repeat steps 6 and 7 until the melting process is

completed.

9. When the process is finished turn off the burner

and close the gas bottle.

10. Clean the basket of debris and prepare it for the next

use.

11. This equipment is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience or

familiarity with the equipment, unless supervised or