BN Products HB-16W User manual

HB-16W Handling Instructions

Page: 1

Important: To reduce rebar breakage,

bend the rebar in increments by throttling the

on/off trigger switch. Bending rebar in smaller

stages allows for stress relief in the metal,

reducing breakage.

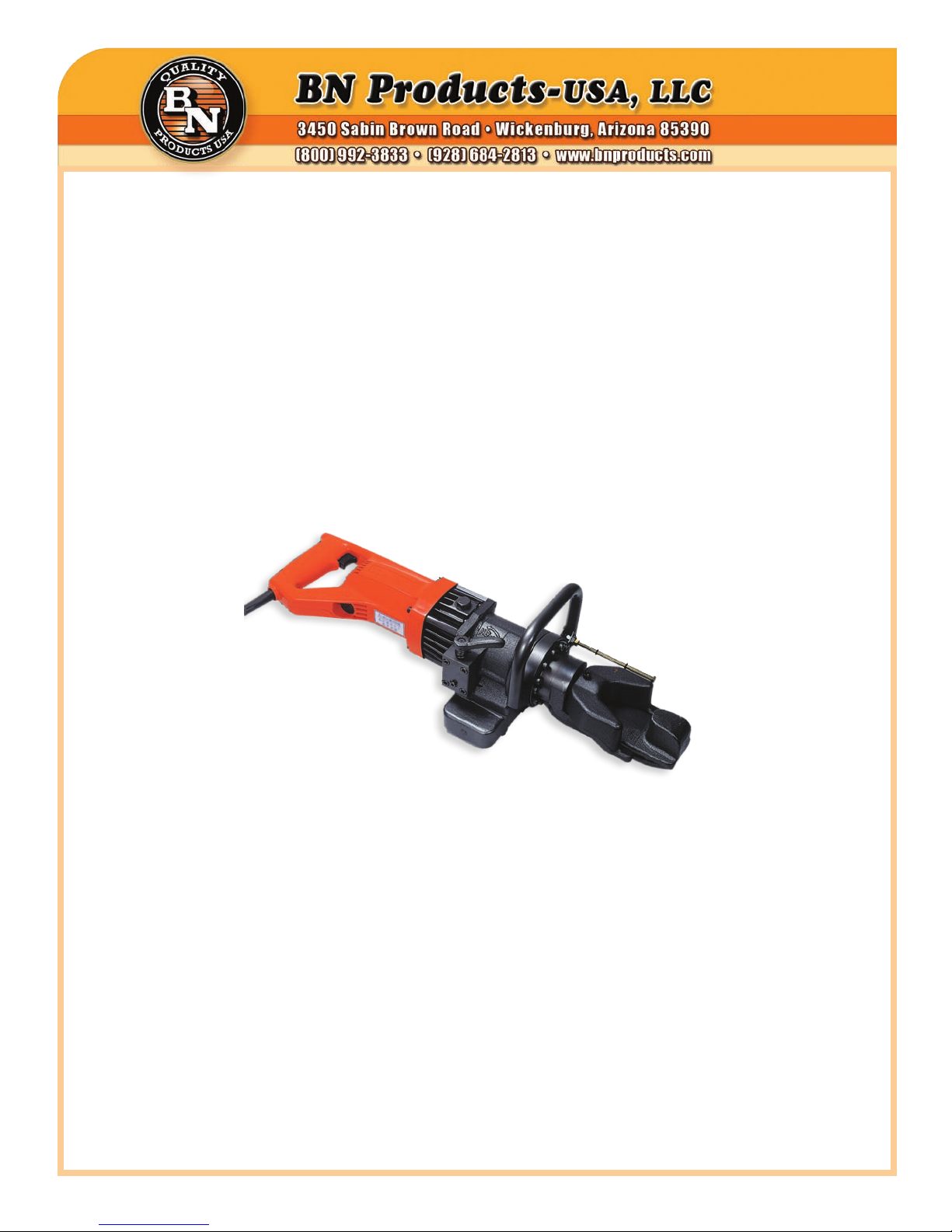

HB-16W Power Rebar Bender

Handling Instructions

Prior to use, please read these instructions carefully.

HB-16W Handling Instructions

Page: 2

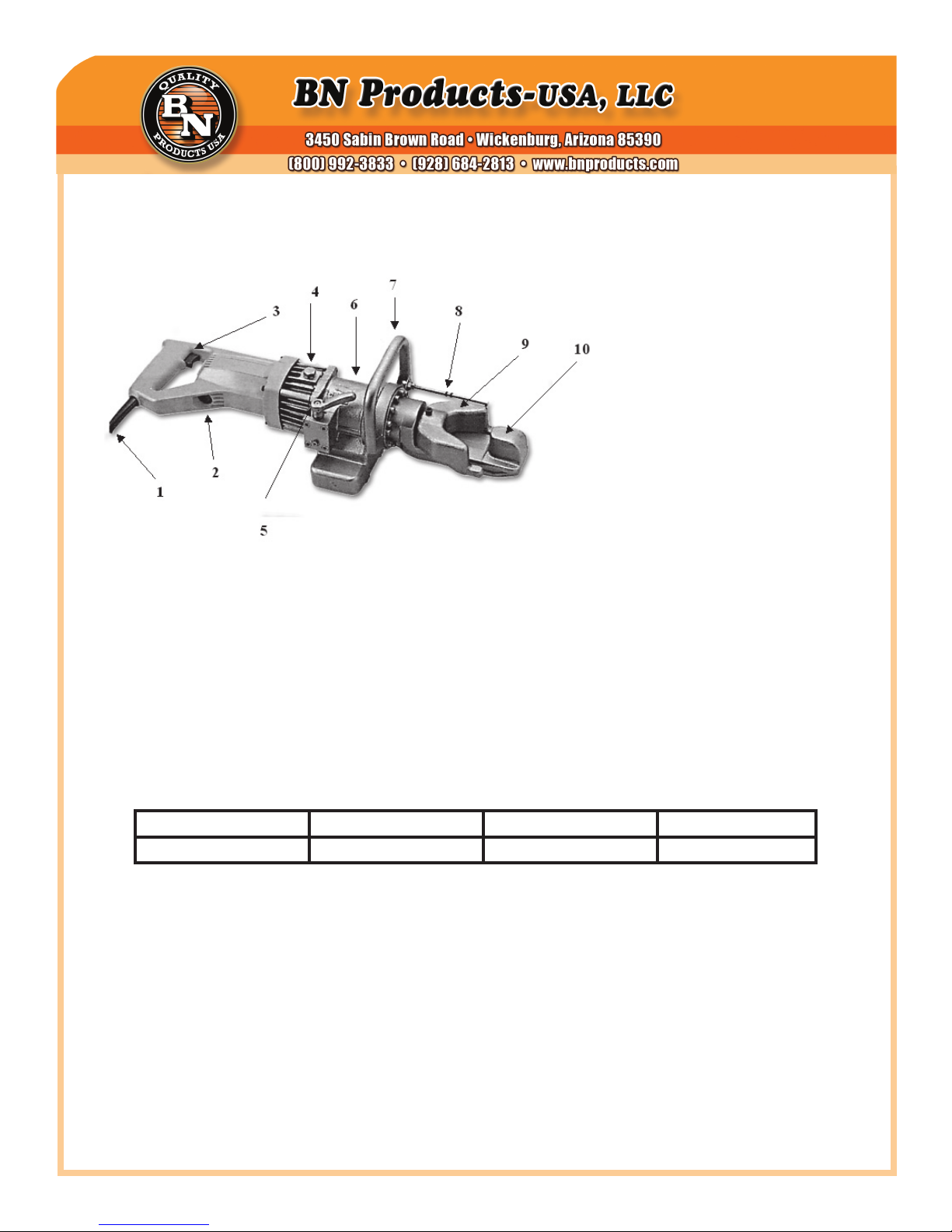

1. Electric cord

2. Electrical brush

3. On/Off switch

4. Oil plug

5. Valve lever

6. Hydraulic cylinder

7. Carrying handle

8. Bending angle marker

9. Pivot shoe

10. Housing

IMPORTANT SAFETY PRECAUTIONS

• Keep hands away from pivot shoe while operating.

• Disconnect tool from socket when not in use and before servicing.

• Maximum number of bar that can be bent at one time: Grade 60 or equivalents.

IMPORTANT -- Do not exceed the maximum number of bars that can be bent at one

time.

IMPORTANT -- Do not try to bend materials that exceed the maximum diameter of bar,

or it will cause either the motor to burn out or a machine failure.

• The machine will only operate on the voltage for which it is designed (with a toler-

ance of 10%). 115 Volt, 50/60 Hz, 10 amps, 1050 watts

• To avoid electrical shock, do not handle with wet hands or use in a damp place.

Diameter of bar 3/8” (10mm) 1/2” (13mm) 5/8” (16mm)

Number of bars 3 Pieces 2 Pieces 1 piece

HB-16W Handling Instructions

Page: 3

General Safety Rules

WARNING: Read all instructions. Failure to follow all instructions listed

below may result in electric shock, re and/or serious injury. The term

“power tool” in all of the warnings listed below refers to your mains-oper-

ated (corded) power tool or battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

Work area safety

•Keepworkareacleanandwelllit.Clutteredordarkareasinviteaccidents.

•Donotoperatepowertoolsinexplosiveatmospheres,suchasinthepresenceofam-

mable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

Electrical safety

•Powertoolplugsmustmatchtheoutlet.Nevermodifythepluginanyway.Donotuse

anyadapterplugswithearthed(grounded)powertools.Unmodiedplugsandmatching

outlets will reduce risk of electric shock.

•Avoidbodycontactwithearthedorgroundedsurfacessuchaspipes,radiators,ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

•Donotexposepowertoolstorainorwetconditions.Waterenteringapowertoolwill

increase the risk of electric shock.

•Donotabusethecord.Neverusethecordforcarrying,pullingorunpluggingthepower

tool. Keep cord away from heat, oil sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

•Whenoperatingapowertooloutdoors,useanextensioncordsuitabletooutdooruse.

Use a cord suitable for outdoor use reduces the risk of electric shock.

HB-16W Handling Instructions

Page: 4

Personal safety

•Keephandsandngersaway.Fromallmovingparts,cuttingblocksandrollerswhile

operating these power tools.

•Stayalert,watchwhatyouaredoingandusecommonsensewhenoperatingapower

tool.Donotuseapowertoolwhileyouaretiredorundertheinuenceofdrugs,alcohol

or medication. A moment of inattention while operating power tools may result in seri-

ous personal injury.

•Usesafetyequipment.Alwaysweareyeprotection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate condi-

tions will reduce personal injuries.

•Avoidaccidentalstarting.Ensuretheswitchisintheoff-positionbeforepluggingin.

Carryingpowertoolswithyourngerontheswitchorplugginginpowertoolsthathave

the switch on invites accidents.

•Removeanyadjustingkeyorwrenchbeforeturningthepowertoolon.Awrenchora

key left attached to a rotating part of the power tool may result in personal injury.

•Donotoverreach.Keepproperfootingandbalanceatalltimes.Thisenablesbetter

control of the power tool in unexpected situations.

•Dressproperly.Donotwearlooseclothingorjewelry.Keepyourhair,clothingand

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in mov-

ing parts.

•Ifdevicesareprovidedfortheconnectionofdustextractionandcollectionfacilities,en-

sure these are connected and properly used. Use of these devices can reduce dust-related

hazards.

Power tool use and care

•Donotexceedthemaximumnumberofbarsthatcanbebentandorcutatonetime.

Refer to additional information contained in these instructions.

•Whenpositioningthebarbetweenthebendingrollersorcuttingblocks,makesureto

layitatonthemachinesurface.Refertoadditionalinformationcontainedinthesein-

structions.

HB-16W Handling Instructions

Page: 5

•Donotcutorbendmaterialsharderthanandorotherthan“Grade60or420MPa”re-

bar.Astheywilleithercrackoryoutorcausemachinefailure.

•Donotforcethepowertool.Usethecorrectpowertoolforyourapplication.Thecorrect

power tool will do the job better and safer at the rate for which it was designed

•Donotusethepowertooliftheswitchdoesnotturnitonandoff.Anypowertoolthat

cannot be controlled with the switch is dangerous and must be repaired.

•Disconnecttheplugfromthepowersourceand/orthebatterypackfromthepowertool

beforemakinganyadjustments,changingaccessories,orstoringpowertools.Suchpre-

ventative safety measures reduce the risk of starting the power tool accidentally.

•Storeidlepowertoolsoutofthereachofchildrenanddonotallowpersonsunfamiliar

with the power tools or these instructions to operate the power tool. Power tools are dan-

gerous in the hands of untrained users.

•Maintainpowertools.Checkformisalignmentorbindingormovingparts,breakage

of parts and any other condition that may affect the power tools operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly maintained

power tools.

•Keepcuttingtoolssharpandclean.Properlymaintainedcuttingtoolswithsharpcut-

ting edges are less likely to bind and are easier to control.

•Usethepowertool,accessoriesandtoolbitsetc.,inaccordancewiththeseinstructions

and in the manner intended for the particular type of power tool, taking into account the

working conditions and the work to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation.

Service

•Haveyourpowertoolservicedbyaqualiedrepairpersonusingonlyidenticalreplace-

ment parts. This will ensure that the safety of the power tool is maintained.

•Keeptoolcleanatalltimesforbestandsafestperformance.Followtheseinstructions

for lubricating and changing parts. Keep hands dry and free of oil or grease. Inspect

switches, tool cords periodically and have them repaired or replaced by an authorized

service center if damaged. Check moving parts for alignment and binding as well as for

breakage and improper mounting. Damaged parts should be repaired or replaced by an

authorized service facility.

HB-16W Handling Instructions

Page: 6

Operating the HB-16W

Rebar Bender

Insert rebar(s) in between the pivot

shoe and housing so that the rebar is

at right angles to the pivot shoe/hous-

ing.

Throttle the on/off switch until the re-

bar has reached your required angle.

After the bend, release the on/off

switch and turn the valve lever to the

open position to return the piston to

the starting position. The piston will

not return automatically when the

on/off switch is released.

HB-16W Handling Instructions

Page: 7

HB-16W Rebar Bender Maintenance

OIL CHECK: The HB-16W is hydraulically operated. It is therefore necessary to check the oil level at fre-

quent intervals, preferably every day. If oil level is too low, power will drop and the piston will not move

properly.

•Extendthepistontothefullestextentofitsstroke.

•Removeoilplugbolt.Onlyremovetheplugwhentheunitiscool

(if it is hot, oil may spurt out suddenly.)

•Thepumpcaseshouldbefulltothebrim.Ifthelevelislow,top

up with Texaco Rando HD 68 hydraulic oil or equivalents. This is a

20-weight hydraulic oil with anti-foam and anti-abrasion proper-

ties. Do not use any other oil.

•Itisimperativethattherebenoairinthesystem.Aftertopping

up, gently tilt the unit and return the tool to the level position. Top

up again and tilt in the opposite direction. Repeat this process until

all air has been extracted. (This is a rather lengthy process, but it is

essential to proper functioning on the unit.)

OPERATING TEMPERATURE: Do not allow the unit to overheat. If the oil temperature exceeds 70 degrees

Centigradeor158degreesFahrenheit,thepistonspeedwillfallandtheunitshouldbeallowedtocooldown

before being used again.

Optional Shoe and Collar for HB-16W Portable #5 Rebar Bender

Optional90degreeBendingShoe(lHB16041A)

and Larger Radius Bending Collar (lHB3107800)

How to install 90 degree Bending Shoe and Larger Radius Bending

Collar:

1. Simply remove the (#8) bending angle marker and (#9) standard

0-135 degree pivot shoe (refer to HB-16W handling instructions).

2. Attach 90 degree bending shoe to piston/ring and tighten cap bolt.

3. Slide larger radius bending collar over housing bending horn and

tighten cap bolt (this will minimize breakage on grade 60 rebar).

4. Place rebar at and level between shoe and collar before starting

bend.

5.Pullthe(#3)on/offswitchuntilthepiston/shoecannotextendanyfurther,oncetherebarisbentto90

degree;donotcontinuetokeeptheswitchinthe“on”positionandthemotorrunningbecausethiswill

cause internal tool damage.

6.Aftercompletingbendimmediatelyswitch“off”andretract(#5)

valve lever, remove bent rebar and repeat this process.

HB-16W Handling Instructions

Page: 8

DBD-16X Portable #5 Rebar Bender

This heavy-duty tool will bend

rebar up to #5 (5/8”) grade 60

at the job site or in your shop.

This strong electrical-mechani-

cal bender has two preset angle

locks for repeating the same

angle bend. The dial-type angle

selector can be set to accurately

bend any angle from 0-180 de-

grees. It has an emergency stop switch and two side

lifting handles that are standard features. Ships com-

plete with set of (6) bending rollers in a steel carry-

ing case, a tool kit, and a standard foot pedal control

switch for hands-free bending.

DBD-32X Portable #9 Rebar Bender

This is a professional heavy-

duty portable table-type

bender. This unit is the larg-

est 115V portable rebar bend-

er available. This tool will

easily bend 1-1/8” Grade 60

rebar 180 degrees in only 8

seconds. It’s fast and accu-

rate bending makes it a valu-

able tool for small to medium size production shops. It

comes standard with a hands-free foot pedal control

switch and a complete bending radius roller set.

DBD-25H Portable #8 Rebar Bender

This heavy-duty portable bender

will effortlessly bend rebar up to

#8 (1”) Grade 60 at job sites or in

your shop. This electrical-mechan-

ical bender has two preset angle

locks for repeating the same angle

bend. The lever-type angle selec-

tor can be set to accurately bend

any angle from 0-180 degrees. Meets ACI 318-05

bending specications. This tool comes complete with

(9) bending rollers in steel carrying cases, a tool kit, a

bender cover, and a standard foot pedal control switch

for hands-free bending.

DBD-20X Portable #6 Rebar Bender

This professional portable re-

bar bender helps save valuable

man-hours by bending rebar up

to #6 (3/4”) grade 60 at the job

site or in your shop. This bender

has two preset angle locks for

repeating the same angle bend.

The dial-type angle selector can

be set to accurately bend any

angle from 0-180 degrees. An emergency stop switch

and two side lifting handles are standard features and

comes complete with set of (6) bending rollers, a tool

kit, and a standard foot pedal control switch for hands-

free bending.

DBD-25X Portable #7 Rebar Bender

This heavy-duty portable rebar

bender helps save valuable

man-hours by bending rebar

up to #7 (7/8”) grade 60 at the

job site or in your shop. This

bender meets ACI 318-05 re-

bar bending specications on

#4, #5 & #6 rebar only. The le-

ver-type angle selector can be set to accurately bend

any angle from 0-180 degrees. It has an emergency

stop switch and two lifting handles that are standard

features. The bender comes complete with a set of

(6) bending rollers, a tool kit and a standard foot ped-

al control switch for hands-free bending.

MorePortableRebarBendersfromBNProduct-USA

The MBC-16B Manual

Bender/Cutter

This is a manual tool that has been

designed to bend and cut rebar

up to #5 (5/8”) grade 60. This new

high-leverage arrangement greatly

reduces cutting and bending effort.

The tool comes complete with a

wood mounting board. An adjustable

2.5” diameter bender roller provides

true 90 and 180 degree bends. Re-

placeable cutting jaws have two open slots with innova-

tive shaped blades to prevent chipping. This tool has a

6 month warranty and pre-paid freight on orders of 6 or

more to one location.

HB-16W Parts Manual

HB-16W

Rebar Bender

Parts Manual

HB-16W Parts Manual

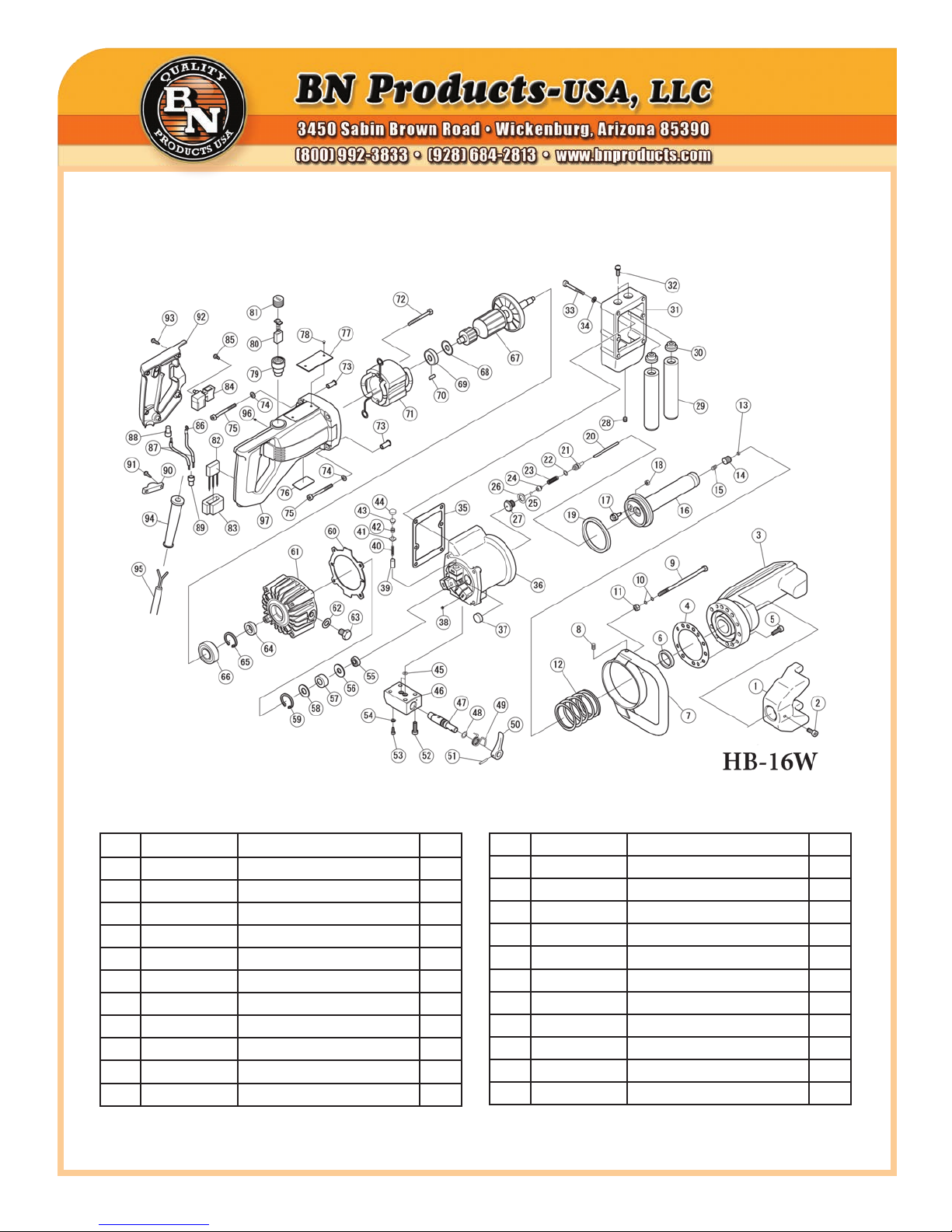

No. Part No. Part Name Qty

1 1HB16041 BENDING SHOE 1

2 7CB06010 CAP BOLT M6×10 1

3 1HB1603A HOUSING 1

4 1HB261 CYLINDRE PACKING 1

5 7CB06028 CAP BOLT M6×28 12

6 3P1031 SEAL PACKING 1

7 1DBR29481 HANDLE 1

8 7SS06012 SET SCREW M6×12 1

9 7B06120 SET BAR M6×120 1

10 70RP5 O RING P5 2

11 7UN0006 U NUT M6 1

No. Part No. Part Name Qty

12 1HB205 RETURN SPRING 1

13 1HB1620 RUBBER PLIG 1

14 7PT1/8 PLUG PT1/8 1

15 7SS06012 SET SCREW M6×12 1

16 1HB16012 PISTON 1

17 1HB2032 RETURN VALVE 1

18 7N0005 NUT M5 1

19 1C1318 SEAL PACKING 1

20 1HB16051 ADJUST ROD 1

21 1DBR2939 SPRING GUIDE 1

22 1DBR2945 O RING P7 1

HB-16W Parts Manual

No. Part No. Part Name Qty

23 1DBR2942 SAFETY VALVE SPRING 1

24 1DBR2938 VALVE SET 1

25 1DBR2943 STEEL BALL 5/32 1

26 1DBR2944 SEAL WASHER WF12 1

27 1DBR2941 SAFETY VALVE SEAT 1

28 7PT1/8 PLUG PT1/8 1

29 1C2570 AIR BAG 2

30 1CM2027 AIR BAG NUT 2

31 1HB207A AIR BAG COVER 1

32 1C1357 AIR BAG SET BPOL 2

33 7CB06050 CAP BOLT M6×50 6

34 7SW0006 SPRING WASHER M6 6

35 1HB208 AIR BAG COVER PACKING 1

36 1HB201B CYLINDER 1

37 3P1044 MAGNET FILTER 3

38 7SS04004 SET SCREW M4×4 6

39 1C1327 RAM 3

40 1C1330 RAM RETURN SPRING 3

41 1C13281 DELIVERY VALVE 3

42 1C1331 DELIVERY VALVE SPRING 3

43 1C13352 SPRING GUIDE 3

44 1C13292 PUMP HEAD SEAL 3

45 1HB1630 O RING P-6 2

46 1DBR2925 VALVE CASE 1

47 1DBR2921 ROTARY VALVE 1

48 1DBR2946 O RING P10A 1

49 1DBR2923 VALVE LEVER SPRING 1

50 1DBR2922 VALVE LEVER 1

51 1HB303 SPRING PIN Φ3×20 1

52 7CB06030 CAP BOLT M6×30 4

53 1DBR5012 BOLT M5×12 1

54 1HB1631 SEAL WASHER W5 1

55 1CW0003 BALL BEARING 698 1

56 1C1325 BEARING GUIDE 1

57 1C13401 NEEDLE BEARING 1

58 1C1325 BEARING GUIDE 1

59 1C1326 SNAP RING HR27 1

60 1C1615 PUMP CASE PACKING 1

No. Part No. Part Name Qty

61 4V0001A PUMP CASE 1

62 1C1305 SEAL WASHER WF10 1

63 7B10015 OIL PLUG 1

64 7SD15257 OIL SEAL 1

65 7HR26 SNAP RING H26 1

66 76002VV BALL BEARING 6002VV 1

67 4V0001B ARMATURE WITH CAM 1

68 4V0001J DUST SEAL A 1

69 7608VV BALL BEARING 608VV 1

70 4V0001G BEARING LOCK 1

71 4V0001C STATOR COIL 1

72 7WNS05060 TAPPING SCREW D5×60 2

73 4V0001K SLEEVE 4

74 7PW0005 PLATE WASHER M5 4

75 7CB05080 CAP BOLT M5×80 4

76 STICKER 1

77 NAME PLATE 1

78 RIVET 2

79 4V0001D BRUSH HOLDER 2

80 4V0001F CARBON BRUSH SET 1

81 4V0001E BRUSH CAP 2

82 4V0001P CONDENSER 1

83 4V0001Q SUPPORT B 1

84 4V0001N SWITCH 1

85 7WB035006 SCREW 3.5×6 2

86 4V0001S TERMINAL 1

87 4V0001T LEAD WIRE 1

88 4V0001W CONNECTOR 50092 1

89 4V0001U CONNECTOR 50091 1

90 4V0001R CORD CLIP 1

91 7FNS04016 TAPPING SCREW 4×16 2

92 4V0001M SWITCH COVER 1

93 7WNS04020 TAPPING SCREW 4×20 5

94 4V0001X CORD ARMER 1

95 4V0001V CORD SET 1

96 7SS04005 SET SCREW 4×5 2

97 4V0001H MOTOR HOUSING 1

HB-16W Parts Manual

Table of contents

Other BN Products Power Tools manuals