MTI Instruments Technical Manual 7001-0005

Revision 1.0 November 5, 2013

iv

TABLE OF CONTENTS

WARRANTY.................................................................................................................................................. ii

FCC NOTICES.............................................................................................................................................. ii

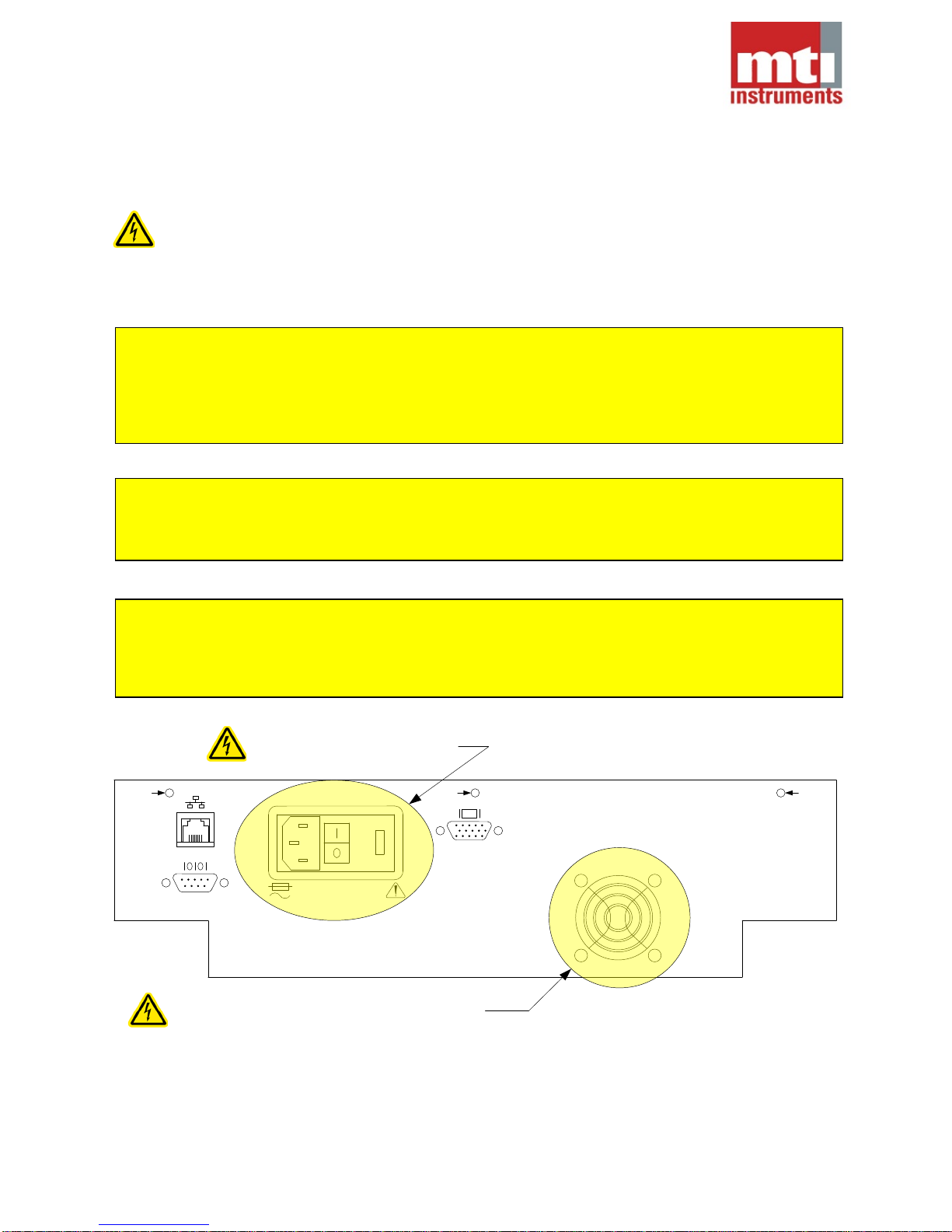

SAFETY WARNINGS ...................................................................................................................................iii

Warning Symbol Definitions ......................................................................................................................iii

DISCLAIMERS..............................................................................................................................................iii

TABLE OF CONTENTS............................................................................................................................... iv

LIST OF FIGURES........................................................................................................................................v

1 INTRODUCTION ...................................................................................................................................1

1.1 Proforma™ 300i Series System Description..................................................................................1

1.2 Proforma™ 300i Series Specifications...........................................................................................1

1.3 Receiving Inspection Procedure.....................................................................................................1

2 INSTALLATION INSTRUCTIONS.........................................................................................................3

2.1 Handling..........................................................................................................................................3

2.2 Environmental Considerations........................................................................................................3

2.3 System Setup .................................................................................................................................4

2.3.1 Proforma™ 300i and Proforma™ 300Gi Setup.......................................................................4

2.3.4 Proforma™ 300OEMi Controller Setup...................................................................................6

2.3.5 Proforma™ 300OEMi Initial Probe Setup ...............................................................................7

2.3.6 Electrical Connections.............................................................................................................8

2.3.7 Power Up.................................................................................................................................8

3 OPERATIONAL INSTRUCTIONS .........................................................................................................9

3.1 Proforma™ 300i and Proforma™ 300Gi ........................................................................................9

3.1.1 Menu Structure Proforma™ 300i...........................................................................................10

3.1.2 Menu Structure Proforma™ 300Gi........................................................................................11

3.1.3 Keypad Functions..................................................................................................................12

3.1.3.2 Units...................................................................................................................................12

3.1.3.3 Zero....................................................................................................................................12

3.1.3.4 Menu..................................................................................................................................12

3.1.3.5 Back () ............................................................................................................................12

3.1.3.6 Left (), Right (), Up (), Down () Arrows..................................................................12

3.1.3.7 Select ()...........................................................................................................................12

3.1.4 Menu Items............................................................................................................................12

3.1.4.1 Mode..................................................................................................................................12

3.1.4.1.1 Continuous.........................................................................................................................12

3.1.4.1.2 5 Point................................................................................................................................12

3.1.4.1.3 Bow....................................................................................................................................12

3.1.4.2 Calibrate.............................................................................................................................13

3.1.4.3 Limits..................................................................................................................................13

3.1.4.4 Rounding............................................................................................................................13

3.1.4.5 Setup..................................................................................................................................13

3.1.4.5.2 Ethernet .............................................................................................................................13

3.1.4.5.3 Export.................................................................................................................................13

3.1.4.5.4 Export to.............................................................................................................................13

3.1.4.5.5 Lamps (Profoma™ 300Gi only).........................................................................................13

3.1.4.5.6 Raw Volts...........................................................................................................................14

3.1.4.5.7 Resolution..........................................................................................................................14

3.1.4.5.8 RS-232...............................................................................................................................14

3.1.4.5.9 Factory...............................................................................................................................14

3.1.4.5.10 Update............................................................................................................................14

3.1.4.5.11 Version...........................................................................................................................14

3.1.5 Calibration Procedure............................................................................................................15

3.1.6 Operational Modes................................................................................................................16

3.1.6.1 Continuous.........................................................................................................................16