Page 3 of 19405-0680 Rev B 2/6/2020

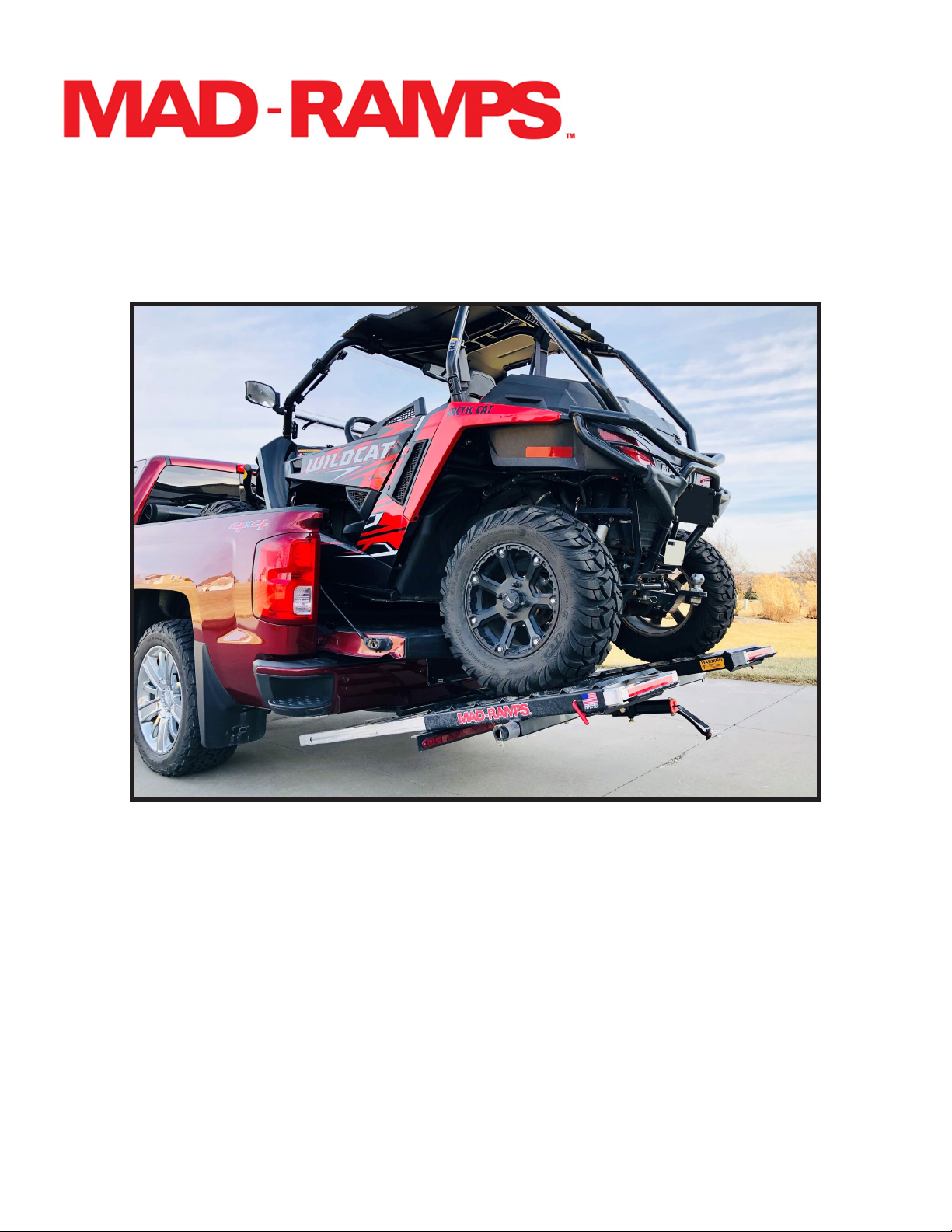

MR1400 MAD-RAMPS Pivoting Ramp System

Installation Instructions

INTENDED USE

The MAD-RAMPS Pivoting Ramp System is intended to load, unload, and transport ATVs, UTVs, Golf Carts,

and Snowmobiles only. Depending on ATV/UTV/Golf Cart/Snowmobile weight, a minimum of a Class III or a

Class IV receiver hitch is required for the MAD-RAMPS Pivoting Ramp System. It is imperative that you check

your owner’s manual to determine the tongue-weight rating for your truck’s specic receiver hitch. Once you

know your truck’s specic tongue-weight rating, you will need to perform one quick calculation: Add together

the total weight of the MAD-RAMPS Pivoting Ramp System (151 pounds) and two-thirds of the weight of your

ATV, UTV, Golf Cart, or Snowmobile (2/3 = machine weight x 0.67). After you have completed this calculation,

you must make sure that the combined weight of the MAD-RAMPS Pivoting Ramp System and two-thirds of

the weight of your ATV/UTV/Golf Cart/Snowmobile is less than the maximum tongue-weight rating for your

truck’s receiver hitch. If this combined weight is more than the maximum tongue-weight rating for your truck’s

receiver hitch, the MAD-RAMPS Pivoting Ramp System should NOT be used on your truck.

NOTE: When using the MAD-RAMPS Pivoting Ramp System with a Golf Cart, ensure there is enough ground

clearance to safety drive the Golf Cart onto the ramps.

Furthermore, it is imperative that you closely inspect your truck’s receiver hitch to determine whether it is in

good working condition. You need to ensure that the structural integrity of your truck’s receiver hitch has not

been degraded from years of use or misuse, or from the use of highway salts and other degrading compounds

that your truck may have encountered.

MAD-RAMPS are DOT compliant for highway travel in the United States. In order to maintain compliance,

three straps must be used to secure your machine prior to transport. For maximum safety, it is recommended

that ratchet straps be used to secure your machine for transport-two at the front of your ATV/UTV/Golf Cart/

Snowmobile and one in the rear, as a minimum.

NOTE: When UTV/Side by Side exceeds 1,000 lbs dry weight, we recommend backing the machine on the

MAD-RAMP. Due to the higher weight and continuous stress load on the MAD-RAMP we make this

recommendation so that more weight is carried by the pickup and less transferred to the MAD-RAMP, which

decreases the continuous load and helps maintain the strength and integrity of the unit.

MAINTENANCE

The MAD-RAMPS Pivoting Ramp System is free from any regular or scheduled maintenance. There

are no bearings, grease ttings, lubrication points, etc. However, several sound practices will ensure

the safety, longevity, and durability of your MAD-RAMPS for years to come.

• Keep all components clean and free from any mud or debris that can accumulate with regular use.

• Use a torque wrench to ensure all of the jam bolts are tightened to 70 ft/lbs each prior to each

use.

• Periodically check to ensure proper function of brake lights, tail lights, and turn signals.

• When not in use for extended periods of time, store MAD-RAMPS indoors.