Owners manual Romar Leisure Furl Rev 0 © Made Engineered BV 2021

Contents

1. Components packing list .................................................................................................................. 2

2. Installation.........................................................................................................................................5

2.1 Preparing the mast ....................................................................................................................5

2.2 Fitting the Leisure furl sail track ................................................................................................6

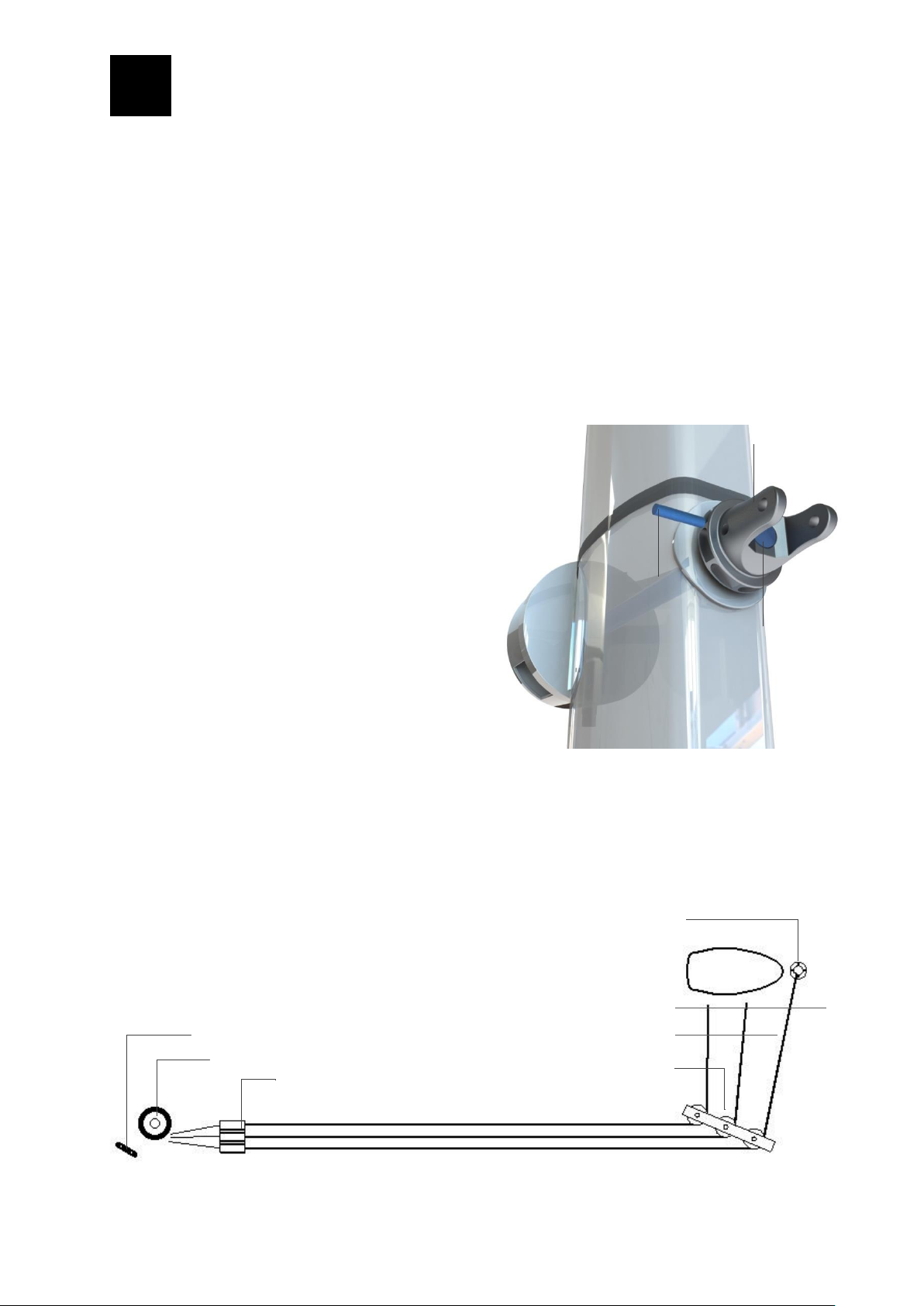

2.3 Fitting the mast components.................................................................................................... 8

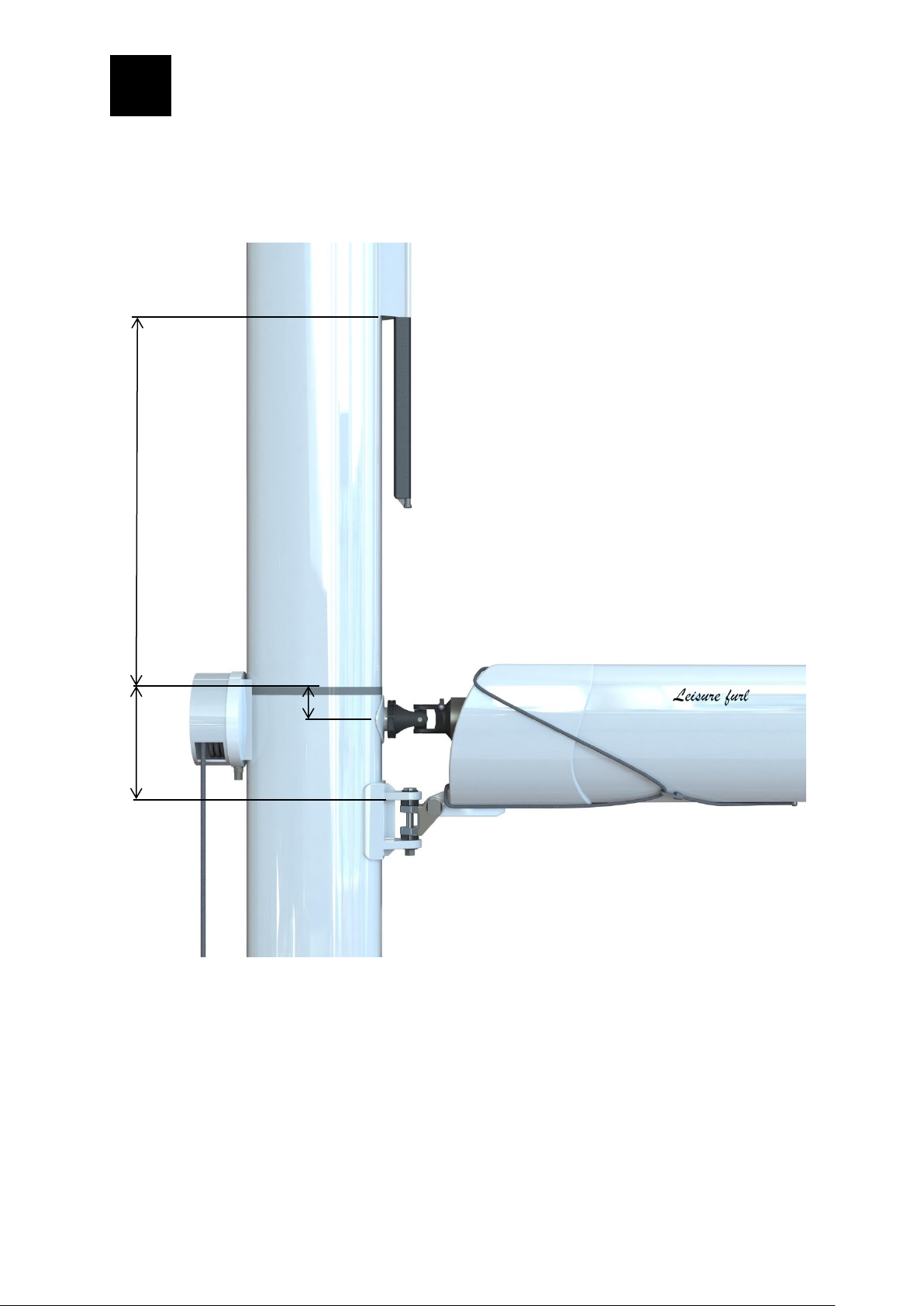

2.4 Fitting the boom and mandrel ................................................................................................... 8

2.5 Deck lay-out ............................................................................................................................. 9

2.6 Sail fitting instructions ............................................................................................................ 10

2.7 Checklist after installation ........................................................................................................11

3. Operation ........................................................................................................................................ 12

3.1 Setting up boom height............................................................................................................ 12

3.2 Hoisting the sail....................................................................................................................... 13

3.3 Furling the sail ......................................................................................................................... 13

3.4 Controlling the sail................................................................................................................... 14

3.5 Sail adjustments ...................................................................................................................... 16

3.6 Operating tips.......................................................................................................................... 17

3.7 Trouble shooting...................................................................................................................... 18

4. Maintenance................................................................................................................................... 20

5. FAQ.................................................................................................................................................. 21

6. Glossary of terms.............................................................................................................................23

7. Contact details ............................................................................................................................... 24

8. Disclaimer .......................................................................................................................................25