GB

Plastimo PWH 500 – PWH 500F

MOUNTING , OPERATION AND MAINTENANCE INSTRUCTIONS

Important safety informations pg.1 Installation pg.2 Wiring diagram pg.16

Warranty pg.1 Operations pg.2 Exploded drawing PWH 500 pg.17

Model classification pg.1 Maintenance pg.3 Exploded drawing PWH 500F pg.18

Electric plant pg.1 Ordering spare parts pg.3

IMPORTANT ADDITIONAL INFORMATION CONCERNING SAFETY ASPECTS OF YOUR ANCHOR WINDLASS

This product isnot designed as a strong point to fasten your anchor rode.Fasten the anchor rode toa strong point such asamooring cleat or similar.

We recommend to use teh vessel’s engine to raise the anchor quickly.

Install always the properly rated circuit breaker to protect the electric plant and the motor from overheating and damages.

Always turn off the main switch, when the product is not in use, to prevent accidental engagement of the product.

Always keep hands and feet away from an operating windlass.If a jamoccurs, turn thewindlassoffatthe main switch before clearing theanchor rode.

Do not use the windlass for different purposes it was designed for.

WARRANTY

Plastimo warrants this product for a period of 2yearssubjected to the conditions listed below :

1. The product must be registered. The registration mustbedone within 30 days from the date of purchase by one of these options :online going

to the web site www.plastimo.com underthe page “Product Registration”and following the instructions orbyfaxing to+33-(0)2 97 87 36 16 the

completed registrationcard attached to the instruction manual.

2. Thiswarrantystarts from thedate of purchase of the product from the originalpurchaser. If the product isfirst equipment of a new boat the

warranty starts from the date of purchase of the boat.

3. This warranty covers original defects in material and workmanship.

4. This warranty is limited to the repair and/or the replacement of the original detective part.

5. The claim ofwarranty must be promptly notified inwriting and sentby fax or e-mail to Plastimo providing the serial number of the productand

the registration warranty number. Plastimo reserves the right to require the proof ofpurchase of theproduct to accept the claim of warranty.

6. The defectivepart/product must be returned to Plastimo. List of authorised distributors isavailableon the web site www.plastimo.com.

7. This warranty doesnot coverfailures dueto : use of the productin applicationsforwhich they are notintended , corrosion , normal wear and

tear , discolouration , unauthorised alteration of the product , improper installation , incorrect use or maintenance of the product , conditions that

exceed the product’sperformancespecifications.

8. This warranty doesnotcover any loss or damages to the original purchaser due to a proven nonconformity of theproduct with the exception of

the cases ruled by the French law.

9. Plastimo reservesthe rightto disclaimthe warranty in case the product be controlled by improperelectric devices and/or in case ofnon

installation of a proper circuit breaker on the electric power line.

Theconsumerstatutoryrights arenotaffected by thiswarranty according to thenationallegislation, disciplining the sale of goods. This warranty is ruled by

the Frenchlaw.Forevery controversy theCourt of Lorient is competent exclusively.

MODEL CLASSIFICATION

FOR YOUROWN SAFETY PLEASE READ THESE INSTRUCTIONS BEFORE INSTALLING OR USING YOUR WINDLASS.

Fill in this form to obtain a complete classification of the installed model.

MODEL 42979

42980 42981 42982

MOTOR 500 Watt 12 Volt 500 Watt 12 Volt 500 Watt 12 Volt 500 Watt 12 Volt

CHAIN ∅6 Iso – Din 766 ∅8 Iso – Din 766 ∅6 Iso –Din 766 ∅8 Iso – Din 766

ROPE ∅12 mm – ½” ∅14 mm – 9/16” ∅14 mm – 9/16” ∅14 mm – 9/16”

Free fall option Free fall option

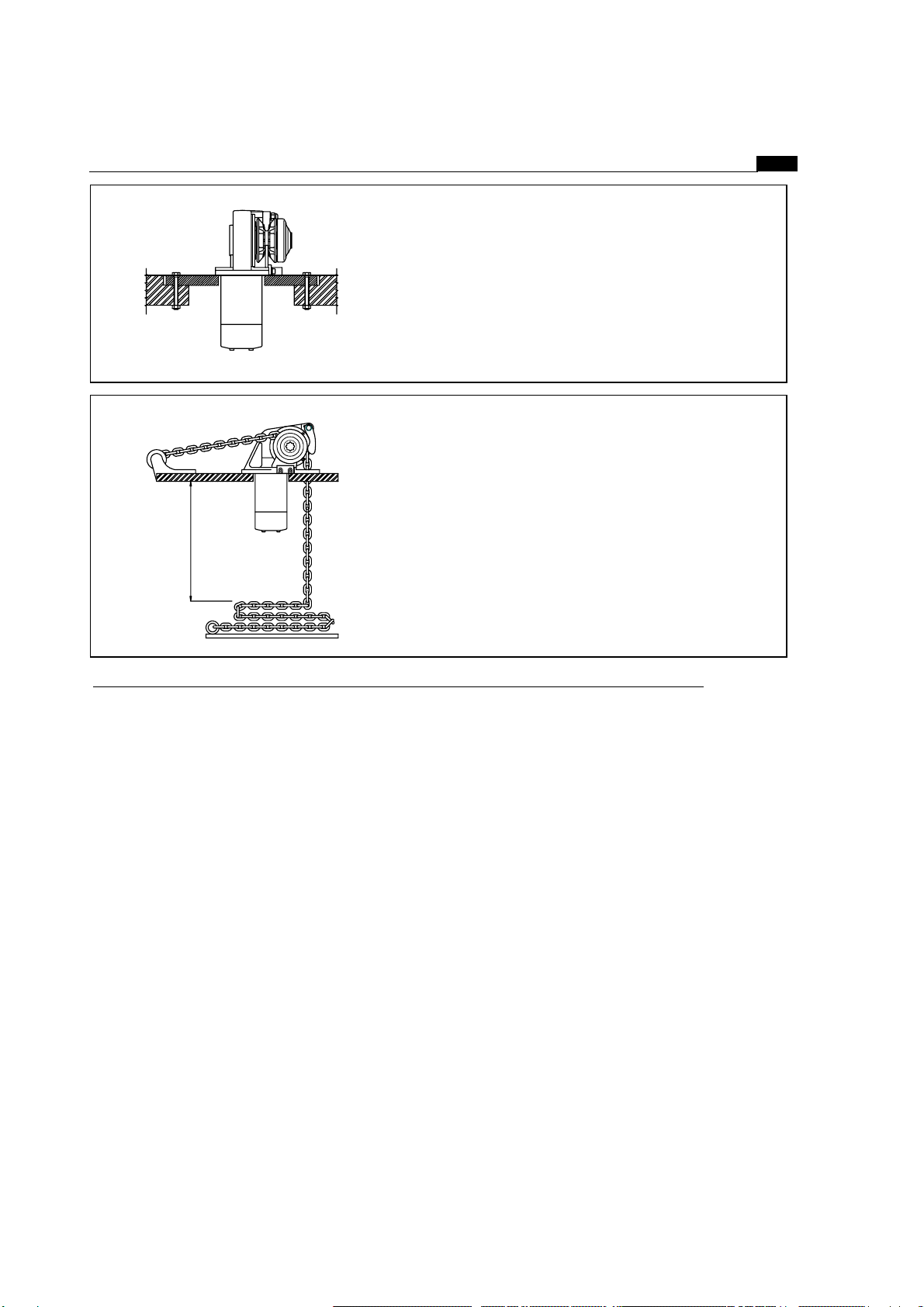

ELECTRIC PLANT

Check that the motor tension corresponds to the electric plant on board. The following schedule shows the suggest minimum battery feeding of the

windlass, the minimum suggested cable section and the proper circuit breaker toinstall onthe powerline.

MOTOR BATTERY CABLES SECTION CIRCUIT BREAKER

500 Watt 12 V 60 Ah 16 mm² 4 AWG 35 Amps

When the windlass is fed by an inferior battery , the performances will be minimum and the battery will rapidly be subject towear and tear. We recommend

to use excellent quality cables , insulated and heat resistant. The cable sections have to be increased by 30% - 50% approx. when the extended cable ,

positive and negative , is longer than 10 mts. or 29' . The cables connected to the electric controls , shown on the wiring diagram by a thin line , should

have a section of 1.5 mm² or 16 AWG approx. Thesevalues refer only to PLASTIMO circuit breakers.

The circuit breaker protects from verydangerous short circuits , protects the windlass motor , avoiding damages due to anomalous absorption and interrupts

the tension to windlass , when desired. The circuit breaker must be installed in a dry , accessible and visible place. For your safety, we recommend that the

windlass and remote are isolated during navigation and reactivated during anchoring. Install the Control Box preferably in a dry place on board. We

recommend to install at least two remote controls to drive the windlass in case one of them gets damaged.

For the protection of electric remote controls, it will be necessary to install a circuit breaker of 5 Ampere.

Commentaire :