Preface

Resilience D Installation guide. © 2016, all rights reserved P a g e | 4

TABLE OF CONTENTS

PREFACE ....................................................................................................................................................................................... 2

safety instructions ............................................................................................................................................................................2

PACKAGE CONTENTS ....................................................................................................................................................................6

Additional materials required (not supplied in package) ................................................................................................................. 6

SYSTEM OVERVIEW ...................................................................................................................................................................... 7

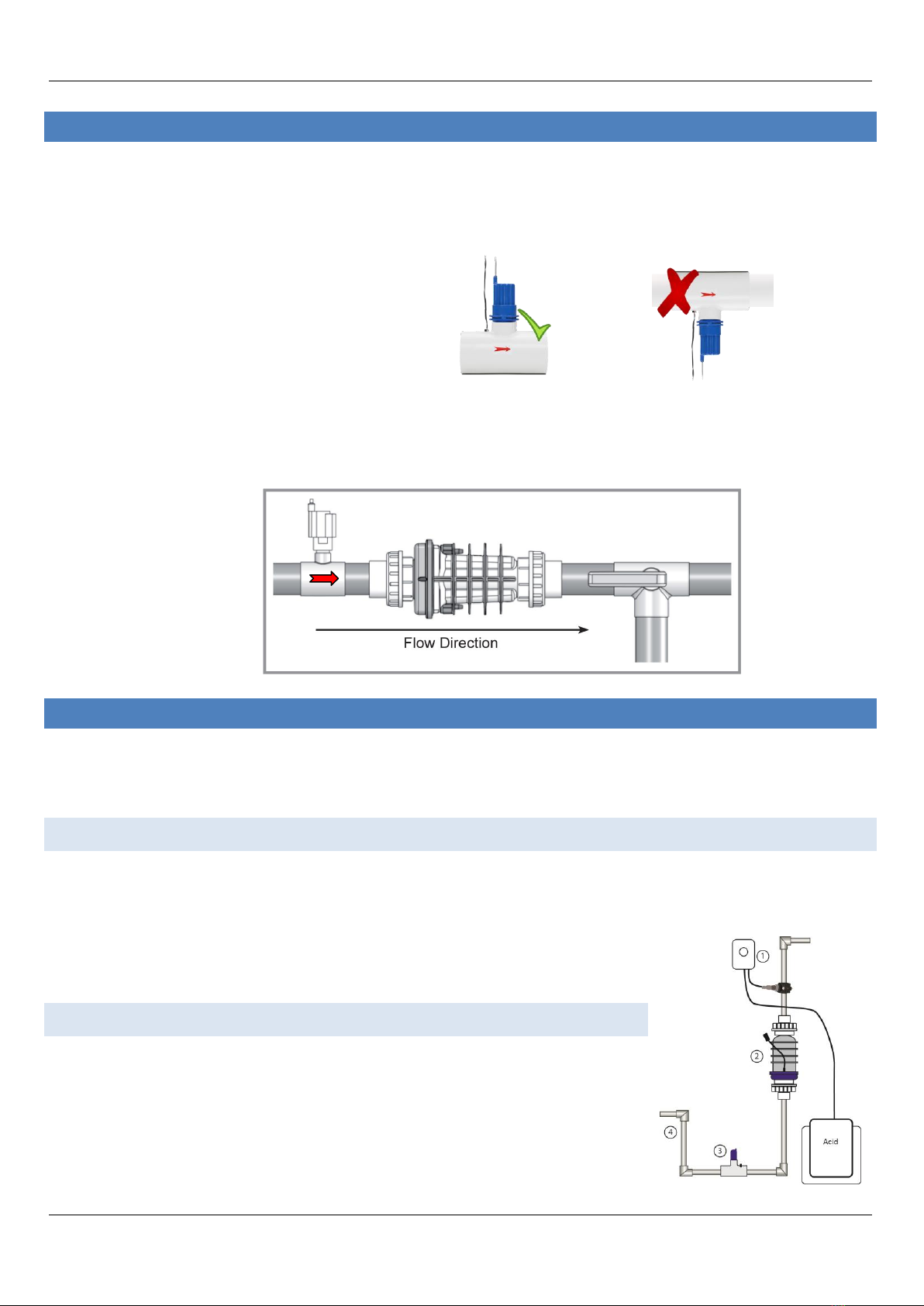

PLUMBING CONFIGURATIONS...................................................................................................................................................... 8

CELL PLUMBING (WITHOUT DOSING ACID PUMP) ........................................................................................................................ 8

INSTALLING THE FLOW SENSOR.................................................................................................................................................... 9

CELL PLUMBING (WITH A DOSING ACID PUMP) ............................................................................................................................ 9

Installing the dosing acid pump ........................................................................................................................................................9

U Shape plumbing configuraiton ......................................................................................................................................................9

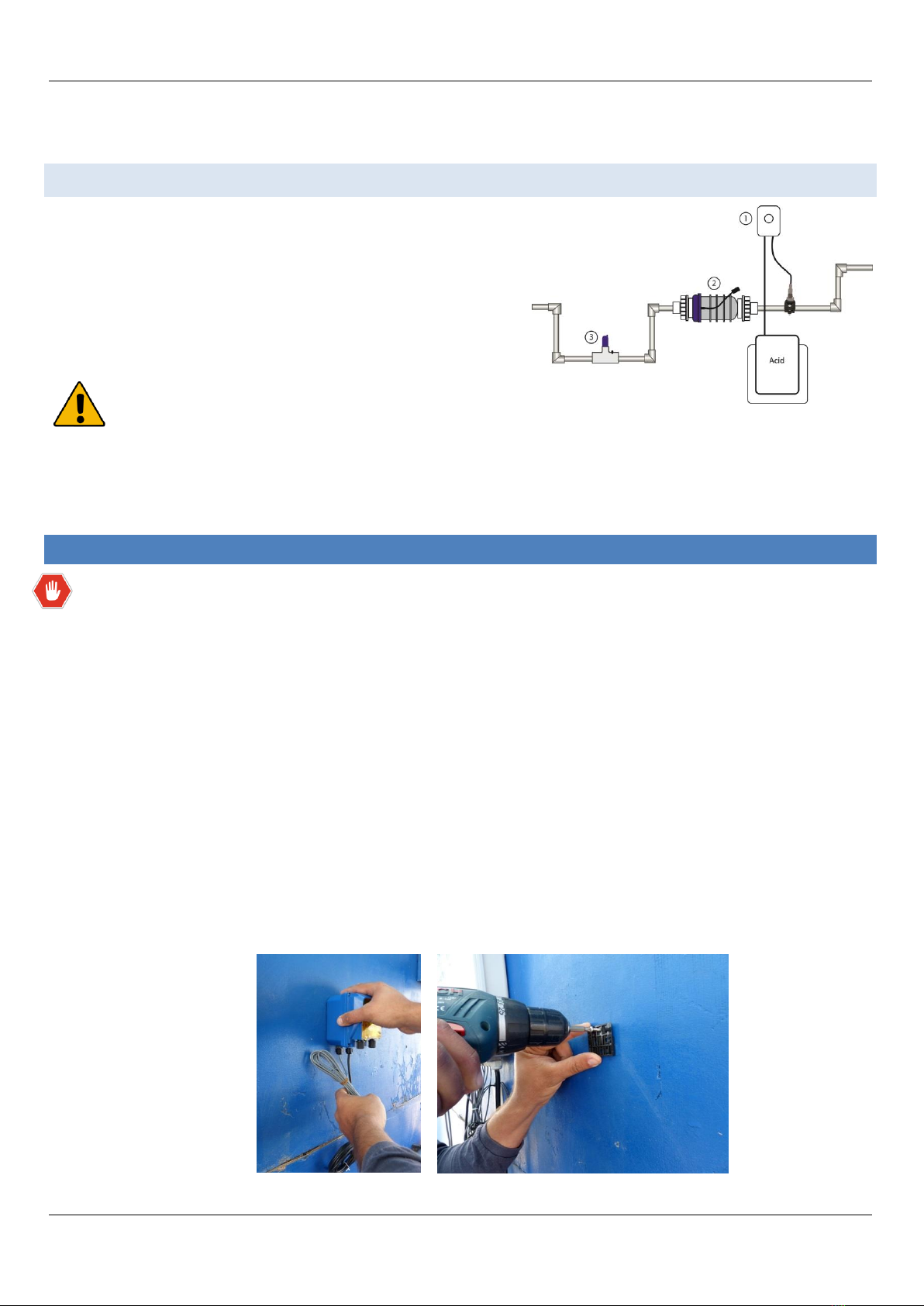

Horizontal plumbing configuration.................................................................................................................................................10

INSTALLATION OF DOSING ACID PUMP ...................................................................................................................................... 10

MOUNTING THE CONTROL BOX.................................................................................................................................................. 13

ELECTRICAL WIRING OF THE CONTROL BOX................................................................................................................................ 14

WIRING THE CELL........................................................................................................................................................................ 15

WIRING THE FLOW SENSOR ........................................................................................................................................................ 15

WIRING THE TEMPERATURE SENSOR.......................................................................................................................................... 16

WIRING THE DOSING ACID PUMP............................................................................................................................................... 16

WIRING THE POOL COVER INDICATION ...................................................................................................................................... 16

STARTING UP.............................................................................................................................................................................. 17

Before adding the salt.....................................................................................................................................................................17

Adding the salt ................................................................................................................................................................................ 18

Calculating the size of the pool ..................................................................................................................................................18

What type of salt should I use? .................................................................................................................................................. 18

Salinity demand table (in kg.) .....................................................................................................................................................19

OPERATING INSTRUCTIONS ........................................................................................................................................................ 20

Filtration ......................................................................................................................................................................................... 20

Related chemistry....................................................................................................................................................................... 20

BASIC OPERATION ...................................................................................................................................................................... 21

Turning the unit on ......................................................................................................................................................................... 22

Operating actions ...........................................................................................................................................................................23

Increasing chlorine output .........................................................................................................................................................23

Decreasing chlorine output ........................................................................................................................................................23

Turbo setting .............................................................................................................................................................................. 23

Mode changing........................................................................................................................................................................... 23

Automatic ST:BY Mode...............................................................................................................................................................23