United Electric Company, L.P. • 501 Galveston • Wichita Falls, TX 76301 • 940-397-2100 • Fax 940-397-2166

10

1-16-07 Part #: 010-200002-000

START-UP

Ensure that ALL RED shipping bolts/screws are removed

and all other bolts and screws are tight.The red hold-

down shipping bolts are located on both sides of the

blower/motor mounting rails and are accessible through

the side access panels.The red sheet metal screws are

located on the discharge duct collar.All must be removed

for the blower assembly to be isolated from the cabinet. See

figure page 11. Check the sheaves to see if they are in

alignment and ensure the set screws are tight. Check for

proper rotation of the blower pulley.Three phase motor

rotation can be reversed by exchanging two of the three

leads at the motor.Not all installations will be on starter.

The rotation of single phase motors can be reversed by

exchanging leads inside the motor junction box. Refer to

motor nameplate. Ensure all filters are installed. Do this

with all doors, panels, etc. in place. Check the amperage

draw of the motor.This should not exceed the nameplate

amps shown on the motor serial plate. Never assume the

voltage and phase on the unit name plate is the same as the

motor is wired.

OPERATIONAND MAINTENANCE

WARNING

Disconnect electrical power to all circuits before servicing

unit.Failure to do so may result in personal injury from

electrical shock or moving parts.

RETURN AIR FILTERS – Filter access is from either side of

unit. Inspect on a regular basis (at least monthly) and clean

or replace.

CAUTION

Never operate unit without a filter or with filter access

door removed.Damage to blower motor may result.

Water Piping -All Drain

Coil is easily cleaned when dry.To check or clean, remove

unit access panel, filter access door and filters. Use

accepted industry methods for cleaning. Remove all foreign

matter from pan and condensate drain line. Check for rust

and holes.

BELTAND PULLEY - Proper pulley alignment and belt

tension must be maintained at all times. Speed is reduced

by adjusting pulley faces so they are farther apart; speed is

increased with faces closer together.Check pulley setscrews

and bolts.

MOTOR - Use electric motor oil or SAE20 nondetergent

oil.Tighten motor mount bracket and base bolts as

required. DO NOT OVER-OIL!!

BLOWER - Check bearing for wear.Replace as required.

Check wheel for accumulation of dirt and clean as

required.

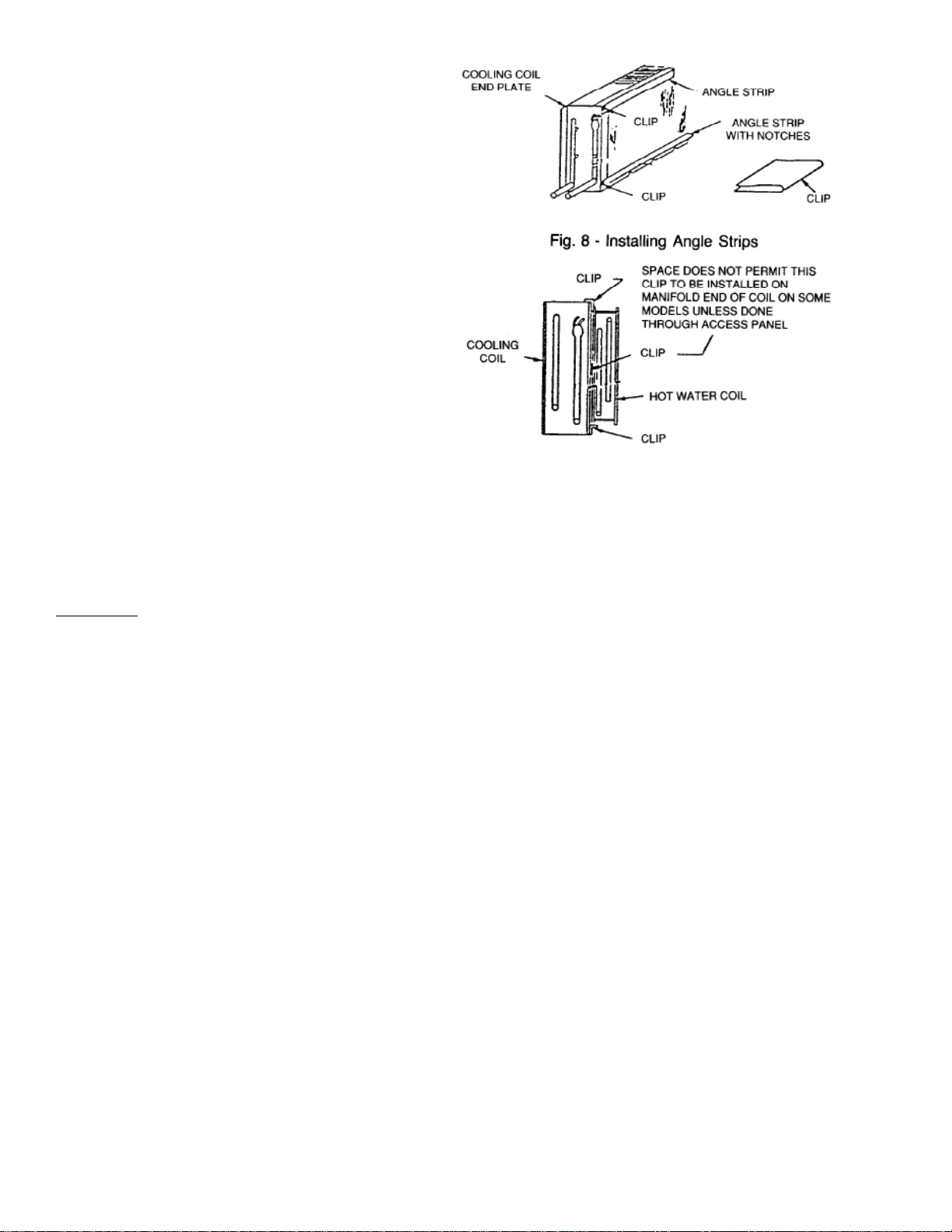

HOTWATER COIL INSTALLATION INSTRUCTIONS

(in reheat position) ON CHILLED WATER COIL UNITS

1. Remove access panel from both sides of cabinet. See (Fig.

8).

2. Remove knockouts from hot water coil stubouts. Coils

stub out the cabinet for left-hand connections (facing

Fig. 9

airflow).

3. Remove 2 galvanized strips from hot water coil package.

Install angle strip with notches resting in drain pan, and 1/2

in. flange pointing toward blower. Secure this angle strip to

end plate of cooling coil by clips supplied in package (Fig.

9). Place clips at each end of strip as close as possible to

flange.

Fig. 8 - Installing Angle Strips

4. Install other angle strip at top of cooling coil, with 1/2 in.

flange resting on top of cooling coil, pointing to rear.

Place clip as high as possible on this strip. Secure it to

end plate of cooling coil. Metal strips prevent air from

bypassing heating coil and serve as support for coil.

5.After strips are secured, install coil inside through access

door opposite side where connections stub out. Raise coil

slightly above drain pan and line up stubouts with

knockout holes in cabinet.When stubouts are extended

through holes, hot water coil should rest on flange of

bottom angle strip with hot water coil and cooling coil end

plates lined up evenly.

6. Secure hot water coil to cooling coil by fastening 2 clips

over cooling coil and hot water coil end plates (Fig. 9).

Note: It is not recommended but, when used in reheat

position with DX coil, install a freeze-stat in system to

prevent freeze-up.MagicAire is not responsible for HW coi

l failure due to freezing from DX system.

HOTWATER COIL INSTALLATION INSTRUCTIONS

(in preheat position)

Follow same procedures as before except cooling coil must

be removed from cabinet.