Page 2 of 18 508196-01Issue 2120

The MHP4 unit is a self-contained electric heating and

cooling unit with optional epoxy-coated coils. This unit has

been examined for compliance with Canadian Standards

Association CAN/CSA-C22.2 No. 236 (latest edition) and

Underwriters Laboratories UL 1995. This unit is also in

compliance with AHRI Performance Standard 210/240.

Any alterations of internal wiring will void these listings and

warranties.

These instructions are intended as a general guide only,

for use by qualied personnel and do not supersede any

national or local codes in any way. Compliance with all local,

state, provincial, or national codes pertaining to this type of

equipment should be determined prior to installation.

Units certied for less than 2% cabinet leakage using ANSI/

ASHRAE 193 (complies with IECC 2015) are identied on

the rating plate.

Installation and servicing of air conditioning equipment

can be hazardous due to internal refrigerant pressure

and live electrical components. Only trained and

qualied service personnel should install or service

this equipment. Installation and service performed by

unqualied persons can result in property damage,

personal injury, or death.

WARNING

For your safety, do not store or use gasoline or other

ammable vapors and liquids in the vicinity of this or any

other appliance. Such actions could result in property

damage, personal injury, or death.

WARNING

The unit must be installed with approved wall sleeve

and louver accessories for safe operation. Improper

installations could result in property damage, personal

injury, or death.

WARNING

Inspection

Upon receipt of equipment, carefully inspect it for possible

shipping damage. If damage is found, it should be noted

on the carrier’s freight bill. Take special care to examine

the unit inside the carton if the carton is damaged. File a

claim with the transportation company. If any damage is

discovered and reported to the carrier, do not install

the unit, as claim may be denied.

Check the unit rating plate to conrm specications

are as ordered.

Limitations

The unit should be installed in accordance with all national

and local safety codes.

Limitations of the unit and appropriate accessories must

also be observed.

The outdoor fan is designed to operate against no more

than .10” w.c. static pressure.

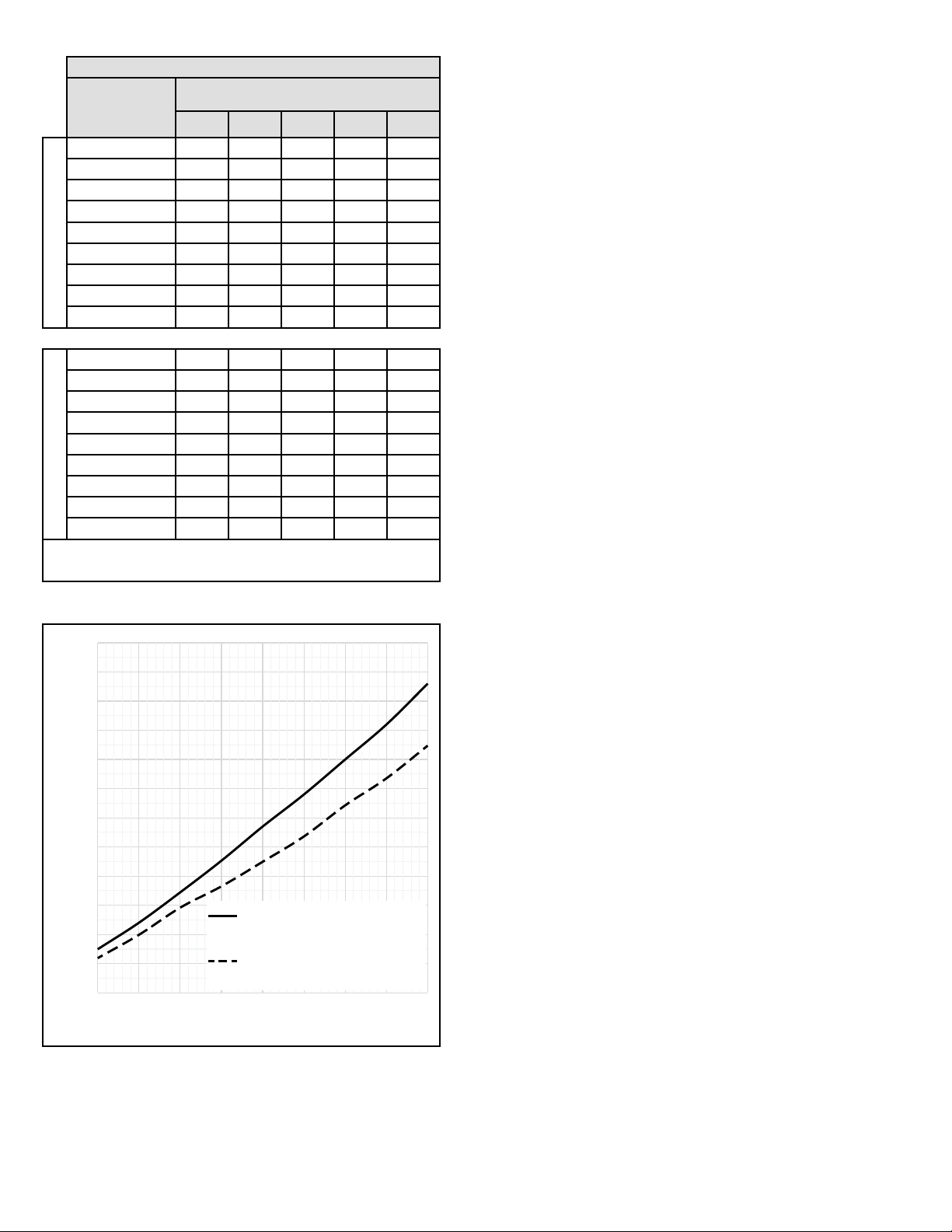

Minimum and maximum operation conditions must be

observed to assure proper system performance. Refer to

Table 1 for the ambient operating limitations of the unit.

Table 1. Ambient Temperature Limitations

Outdoor Ambient Air Temperature °F

Minimum DB Maximum DB

Cool Cool Heat

65 115 75

Indoor Ambient Air Temperature °F

Minimum Maximum

DB/WB DB DB/WB DB

Cool Heat Cool Heat

62/57 50 90/72 80

DB = Dry Bulb

WB = Wet Bulb

Location

For information on wall sleeves and louver accessories,

see the Accessories section.

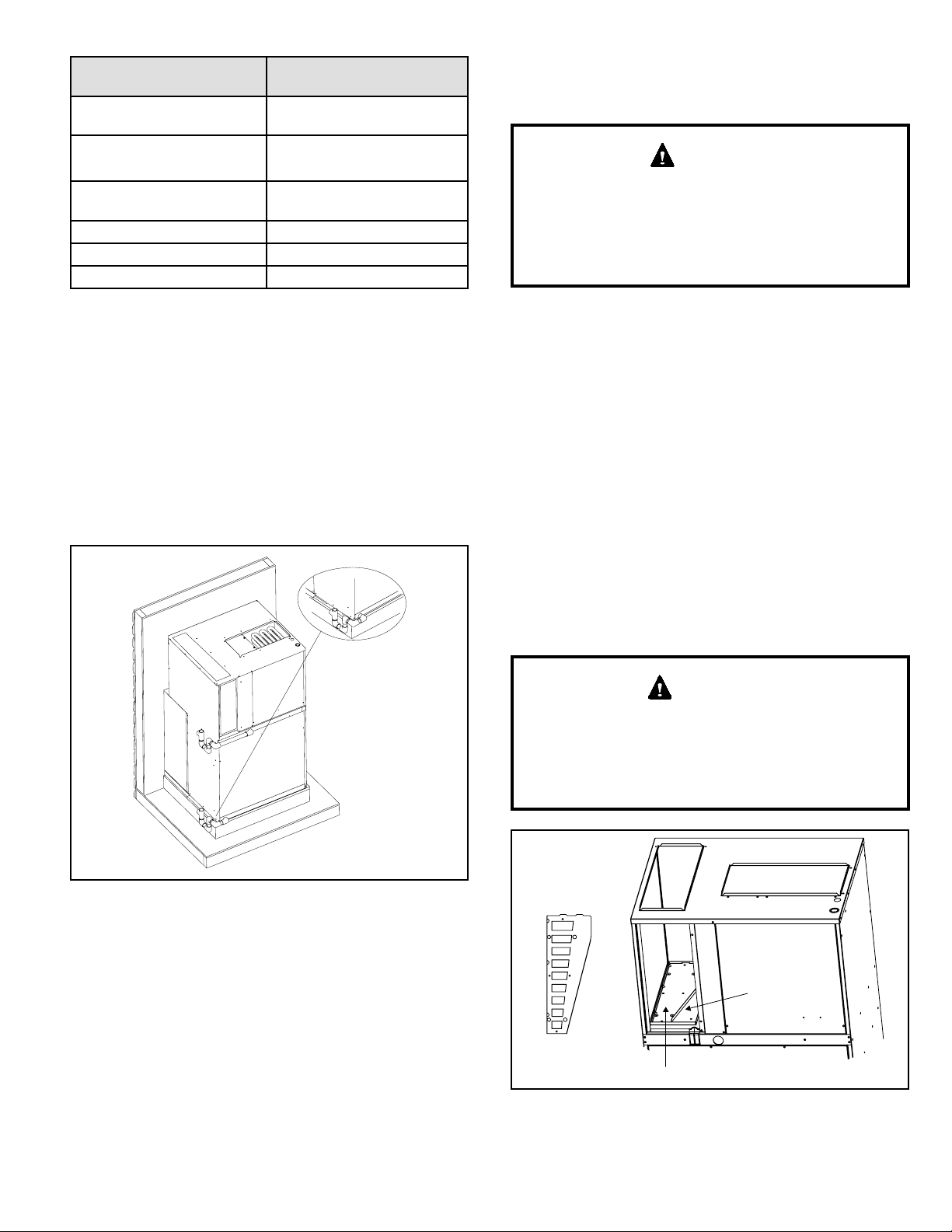

This unit is designed to be installed in up to the wall (exterior

wall) installation only. Refer to Figure 2 for additional

details. Accessibility clearances must take precedence

over re protection clearances.

The outside of the unit may be ush with the face of

the exterior wall, and it should not be obstructed with

trees, landscape materials, or building structure. Unit

can be installed recessed with appropriate wall sleeve

accessories. There is no minimum clearance required on

locating the unit to an interior corner of a building.

If the unit is installed in a residential garage, it must be

located or protected to avoid physical damage by vehicles.

The unit must be installed so that no electrical components

are exposed to water.

This unit must be installed level to allow for proper

drainage of the unit base pan and indoor drain pan.

CAUTION