Figure 5C. ExplodedView of Parts BelowBackPanel.

ADJUSTMENTS

The “one way” pawl-actuated clutch on rear

shaft extension of rewind motor (102) operates so that,

as tape is unwound from payoff spindle (2), a certain

amount of drag is imparted to motor shaft, which is

then transmitted to tape as tension. When rewinding,

pawlis disengaged from ratchet disc (111) by direction

sensitive rewind paw1 spring (llO), allowing motor

shaft to turn freely. A rapid rewind results.

HeadAlignment

1. The primary purpose in head alignment is to

provide maximum frequency response.

(NOTE: Before attempting to align record-reproduce

head, make certain difficulty is not due to an accumu-

lation of tape coating residue on pole surfaces.)

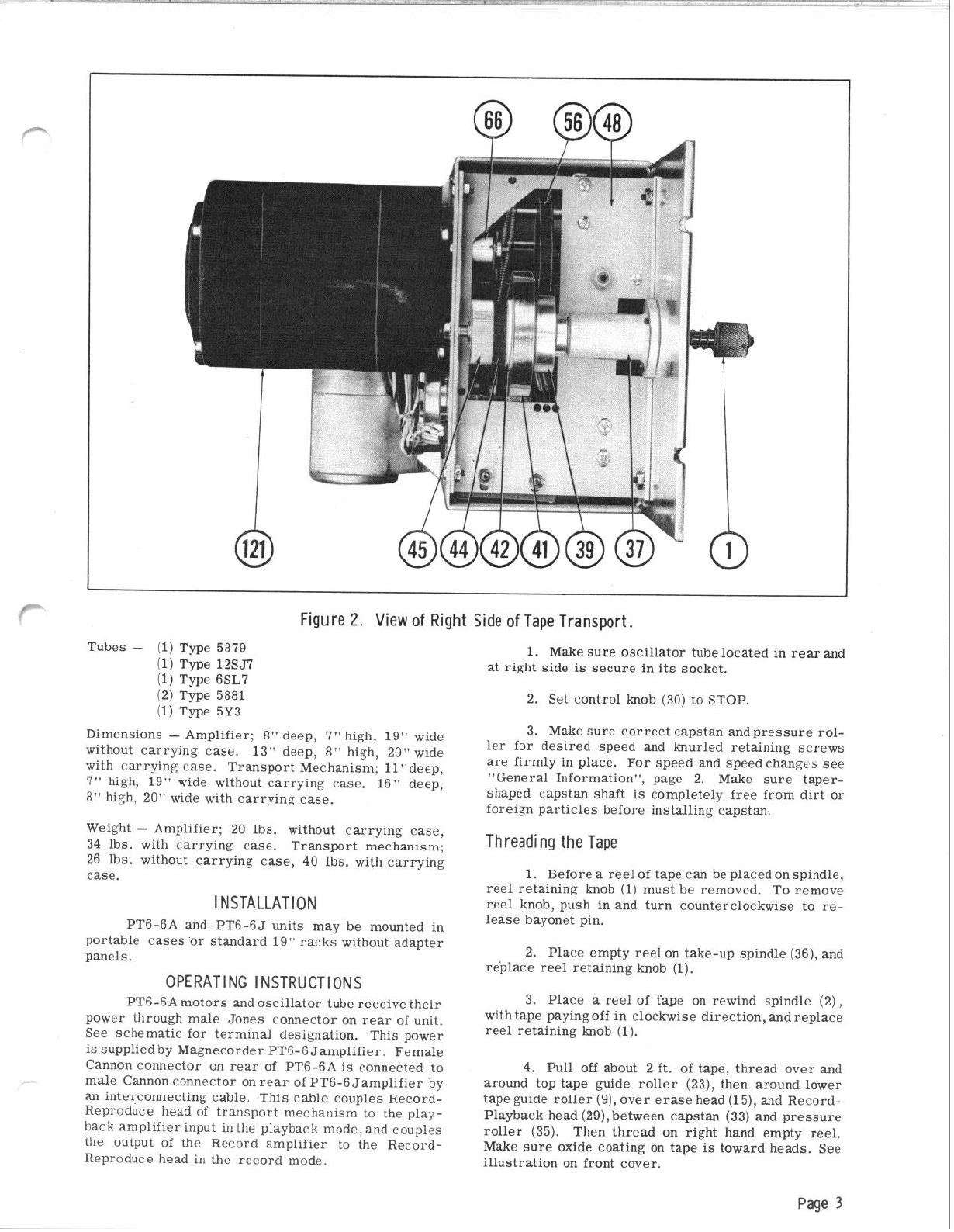

Drive System

The drive system is driven by main drive motor

(121) throughtwo rubber-tired idler wheels (67and 70),

mounted on sliding suspension arm supports (85 and

87). Idler wheels (67 and 70) are held in contact with

hub of flywheel assembly (83) and drive motor shaft

(121) by springs (71). This, in turn, drives capstan

(33), which is secured to flywheel shaft and, with

pressure roller (35) conveys tape at aconstant speed.

Take-UpSystem

Take-up shaft (36) is driven by forward idler

wheel (61), making contact with drive motor shaft and

take-up hub (41). Take-up hub (41) is concentrically

mounted on take-up shaft (36) and is coupled to the

shaft through a clutch assembly (39 thru 46) similar

to that in the rewind system. With tape properly

threaded on recorder and mechanism in “Forward”,

take.-up shaft (36) slips a certain amount due to pres-

sure applied on tape by slower running capstan and

pressure roller. Consequently, tension imparted to

tape causes tape to move from one reel to the other

without throwing or stalling.

2. The right mounting screw of the record -

reproduce head is drawn up securely. This side of

head holder is provided with a rocker action. Left

adjustment screw (14) is associated with a compres -

sion spring. Rotating this screw changes gap align-

ment with respect to tape. Proper alignment is

achieved when maximum signal, at a given setting of

the gain control, is reproduced from alignment tape,

as alignment screw (14) is turned in or out.

SolenoidAdjustments

The Plunger of Solenoid (72), energized during

rewind, should pull against springs (64) and lift idler

wheel (61) away from drive motor shaft by l/16”, but

maintain contact between idler wheel (61) and the

take-up wheel (41). When mechanism is switched from

“Rewind” to “Stop” the solenoid relaxes, spring (64)

returns idler wheel (61) into contact with drive motor

shaft. This shaft is not turning and in turn, idler wheel

(61) is prevented from turning: This stops free ro-

tafion of Take-up Wheel (41), acting as a brake on the

take-up shaft.

Solenoid (72) should be positioned to accomplish

the above. The solenoid is mounted by two screws in

Page8