Akai 4000DS Mk-II User manual

Other Akai Tape Deck manuals

Akai

Akai GX-646 User manual

Akai

Akai GX-210D Operating and installation instructions

Akai

Akai GX-230 User manual

Akai

Akai X-201D User manual

Akai

Akai GX-370D User manual

Akai

Akai GX-266D User manual

Akai

Akai 4000DS Mk-II User manual

Akai

Akai X-2000 User manual

Akai

Akai 4000DB User manual

Akai

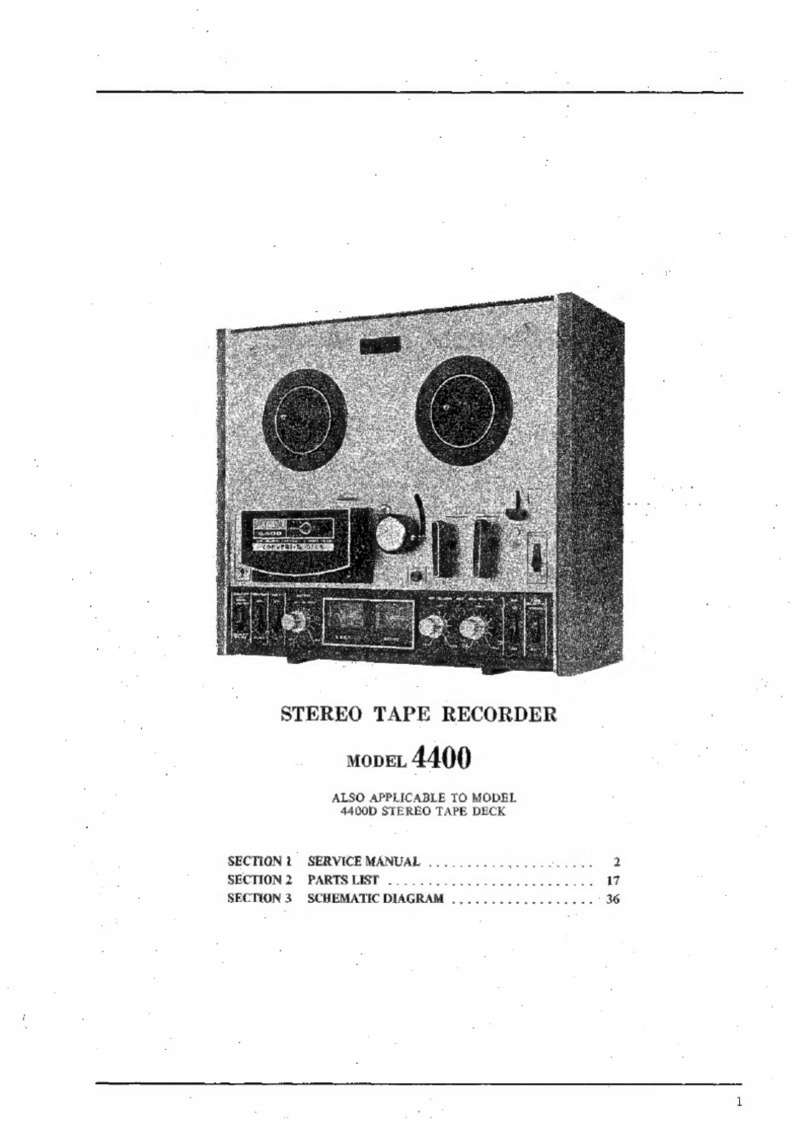

Akai 4400 User manual