iii

Table of Contents

SAFETY PRECAUTIONS .........................................................................................................................I

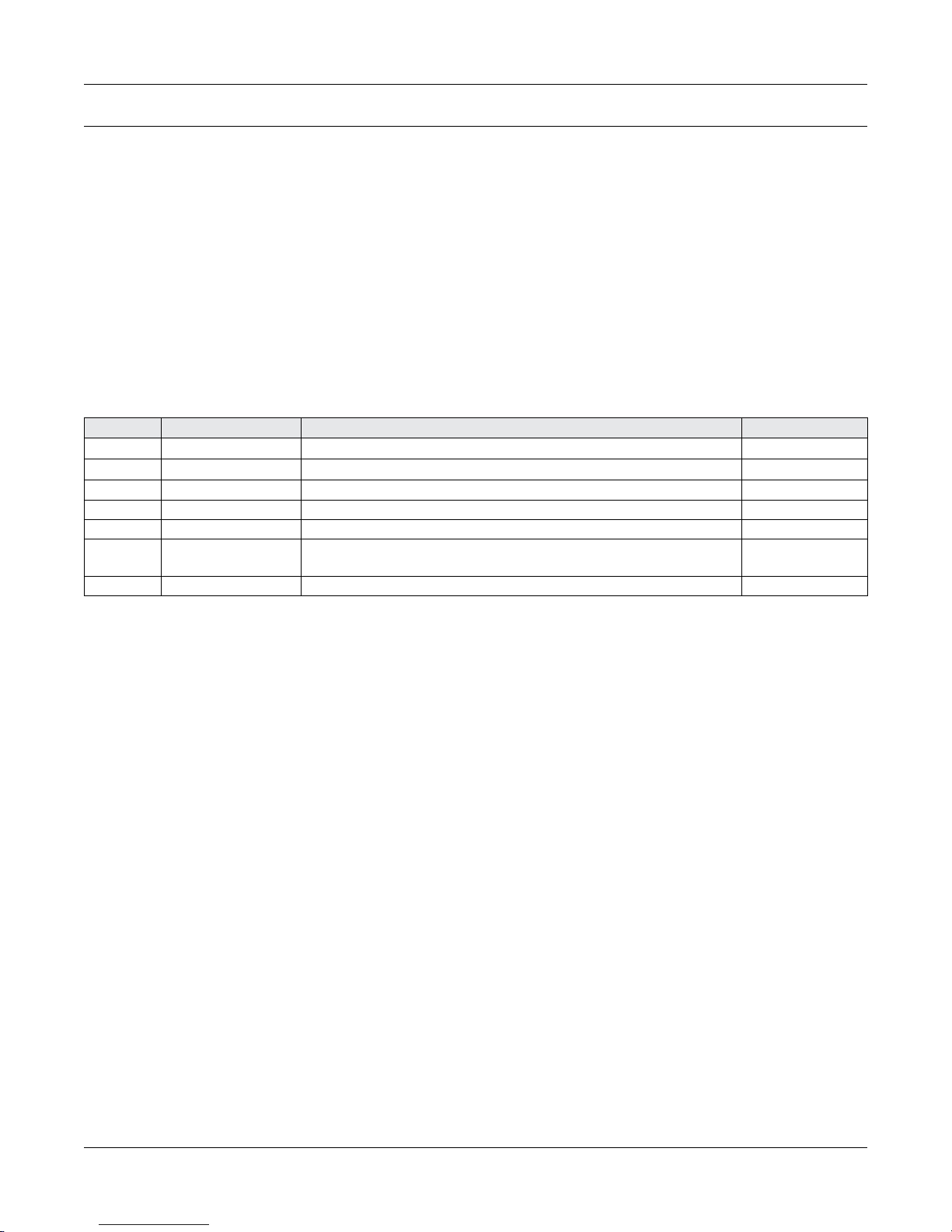

REVISIONS TO THIS MANUAL ...............................................................................................................II

REVISION DATE .................................................................................................................................................................II

TABLE OF REVISIONS ......................................................................................................................................................II

TABLE OF CONTENTS ..........................................................................................................................III

TABLE OF FIGURES ........................................................................................................................................................ IV

PREFACE ................................................................................................................................................ V

PURPOSE OF THIS MANUAL ......................................................................................................................................... V

WHO SHOULD USE THIS MANUAL .............................................................................................................................. V

MANUAL ORGANIZATION ............................................................................................................................................. V

1. INTRODUCTION .................................................................................................................................1

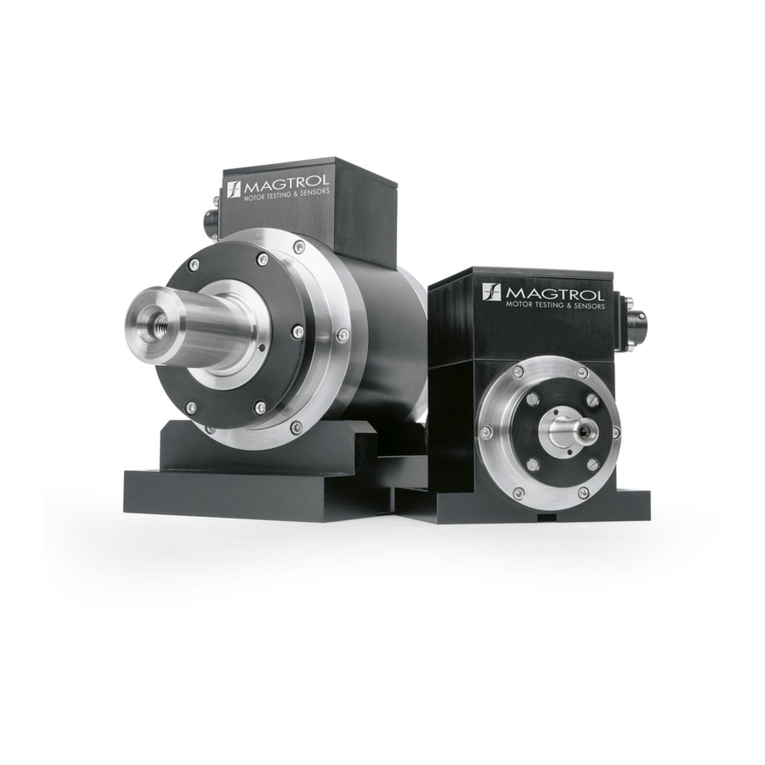

1.1 GENERAL INFORMATION ........................................................................................................................................ 1

1.2 DESCRIPTION ............................................................................................................................................................. 1

1.3 DATA SHEETS ............................................................................................................................................................. 2

1.3.1 TM 301 – TM 308 ........................................................................................................................................... 2

1.3.2 TM 309 – TM 313 ........................................................................................................................................... 6

1.3.3 TM 314 – TM 317 ......................................................................................................................................... 12

2. INSTALLATION / CONFIGURATION ................................................................................................17

2.1 MOUNTING POSSIBILITIES ................................................................................................................................... 17

2.1.1 Suspended Installation .................................................................................................................................. 17

2.1.2 Supported Installation ................................................................................................................................... 17

2.1.3 TM/TMB in Vertical Installation ................................................................................................................... 18

2.2 PARASITIC FORCES ................................................................................................................................................. 18

2.2.1 Radial Forces (Bending) ............................................................................................................................... 19

2.2.2 Axial Forces (Thrust) .................................................................................................................................... 20

2.3 MEASURING SHAFT VIBRATIONS ....................................................................................................................... 21

2.3.1 Permitted Vibrations on Measuring Shaft ..................................................................................................... 21

2.3.2 Torque Signal Conditioning Electronic Circuit ............................................................................................. 23

2.4 MOUNTING LIMITS ................................................................................................................................................. 24

2.4.1 Dynamic Torque ............................................................................................................................................ 24

2.4.2 Natural Frequency of Drive Train ................................................................................................................. 24

2.4.3 Natural Measuring Shaft Torsional Frequency ............................................................................................. 26

2.4.4 Maximum Dynamic Amplitude..................................................................................................................... 27

2.5 PROTECTIVE SYSTEMS .......................................................................................................................................... 27

2.6 ELECTRONIC SIGNAL PROCESSING .................................................................................................................... 29

2.6.1 Model 3410 Torque Display .......................................................................................................................... 29

2.6.2 Model 6400 Torque Transducer Display ....................................................................................................... 30

2.6.3 Model DSP6001 Programmable Dynamometer Controller .......................................................................... 31

2.7 ELECTRICAL CONNECTIONS ............................................................................................................................... 32

2.7.1 Grounding ..................................................................................................................................................... 32

2.7.2 Connecting Cable .......................................................................................................................................... 33

2.7.3 Connection to Non-Magtrol Electronics ....................................................................................................... 34

3. OPERATING PRINCIPLES ...............................................................................................................36

3.1 TORQUE TRANSDUCER ARCHITECTURE .......................................................................................................... 36