4

BA314001-en

1.5 Safety Instructions for Servicing

Repair work of any kind (other than routine servicing expicitly covered in this operator manual)

may only be done by authorized service technicians. In case of non-compliance the warranty

becomes void.

2 Description

The MPM 4M is a self-contained maintenance tool which continuously measures the

concentration of fine particulate matter (PM) in the exhaust of diesel engines, using

standardized tests developed in joint government/mining industry projects.

The measurement principle is based on well-established laser light-scattering technologies,

which are widely accepted and used for measurement of particle concentrations in numerous

laboratory and industrial applications. The MPM-4 takes this technology several steps further,

by adding sophisticated automated data processing capabilities and by ruggedizing the design

to withstand the harsh operating conditions. Simple and accessible user maintenance greatly

reduces the need for inconvenient “back-to-base” servicing.

Ensuring the accuracy and consistency of measurement is vitally important. As well as

performing an auto-zero at the start of each test, the instrument’s calibration can be checked by

the operator in less than a minute, using the supplied calibration device.

User-maintainability is also a high priority. If a particularly dirty or wet sample is ingested and

the instrument’s response is degraded because of dirt on the optical elements, both the laser

module and/or the detector head can be removed in seconds, without tools.

Both of these items can be quickly cleaned, using the same cleaning solution and polishing

cloth used for spectacle cleaning. In this situation, previous examples of this type of instrument

would require service at the manufacturer or distributor, including possible replacement of

expensive components.

The MPM-4M design ensures that both the laser and the detector are not only readily acces-

sible, but importantly are also positively and repeatably aligned upon re-insertion, without affec-

ting the instrument calibration. This can be confirmed using the supplied calibration device.

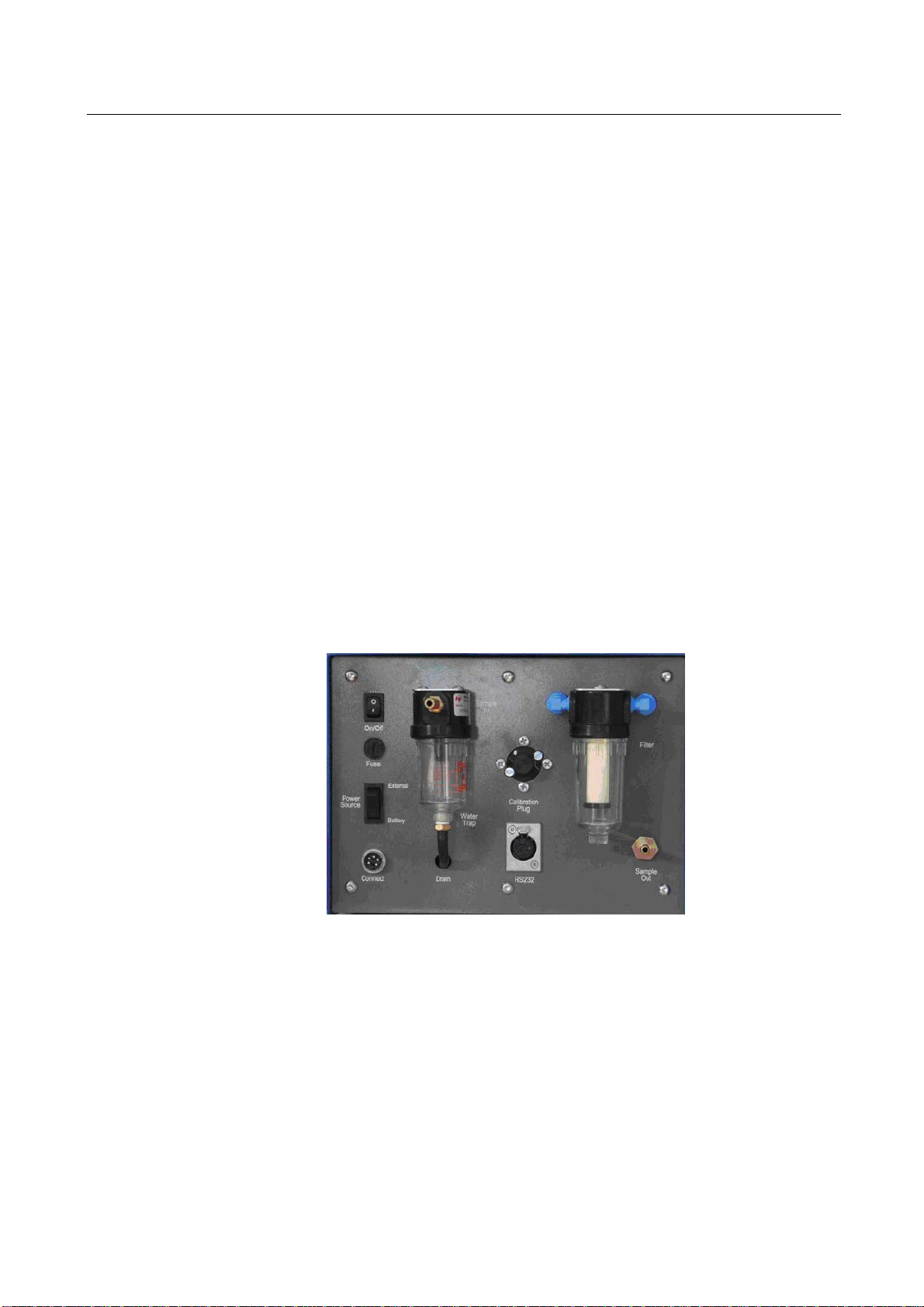

A single HEPA grade filter is used to remove over 99.9% of particles before releasing the mea-

sured sample stream into the atmosphere. The filter unit is a standard screw-off housing design

with a disposable filter element. No tools are required to change the filter element. A second

disposable HEPA filter is located inside the case to continuously filter a stream of ambient air

which protects the optical elements from contamination by soot or moisture in the sample.

Added protection for the measuring system is provided by an automatic drain pump, which

operates every 60 seconds to remove any accumulated condensate from the water trap.

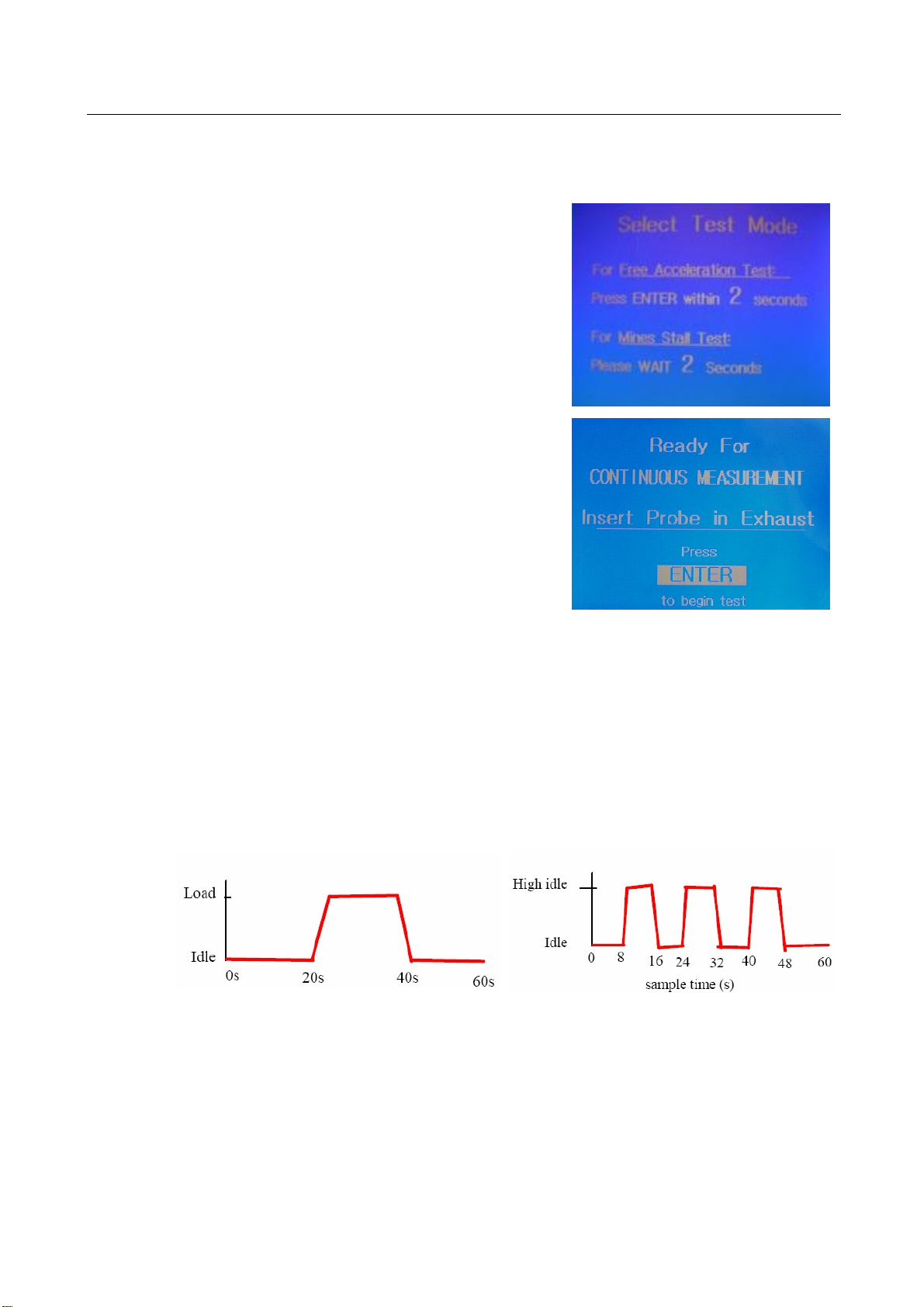

Unlike other DPM measurement methods which require off-line analysis or manual interpreta-

tion, the MPM-4 continuously displays DPM concentration, and provides an immediate overall

test result at completion of a test. This means that maintenance decisions can be made without

delay, and the effectiveness of any maintenance action can be confirmed prior to releasing the

equipment back to the work place.

Weighing less than 9kg (including its integral battery), the instrument is self-contained and is

designed for stand-alone operation. With around 2½ hours testing on a single charge, most

operators prefer to use the instrument on battery power.

Alternatively, the instrument can operate continuously on an external 12V supply. A regulated

12 V DC power pack, which can be connected to a 100-250V, 50/60 Hz AC supply, is supplied

as standard with the instrument. Operating power consumption is typically less than 25 watts.