UMDIO128CO Version 2.0.1 Preliminary Documentation – May be Subject to Change iii

TABLE OF CONTENTS

1. OVERVIEW OF CONTROLLER………………...…………………………………..………………………..5

1.1. Description of 12 Input, 8 Output Controller………………….…………………………………….. 5

1.2. LED Indicator………………...………………………………………………………………………… 6

1.3. Error Detection and Reaction………………………………………………………………………… 7

1.4. Digital Input Function Block…………………………………………………………………………... 8

1.5. Digital Output Function Block………….……………………………………………………………... 10

1.6. Miscellaneous Function Block……………………………………………………..…………………. 11

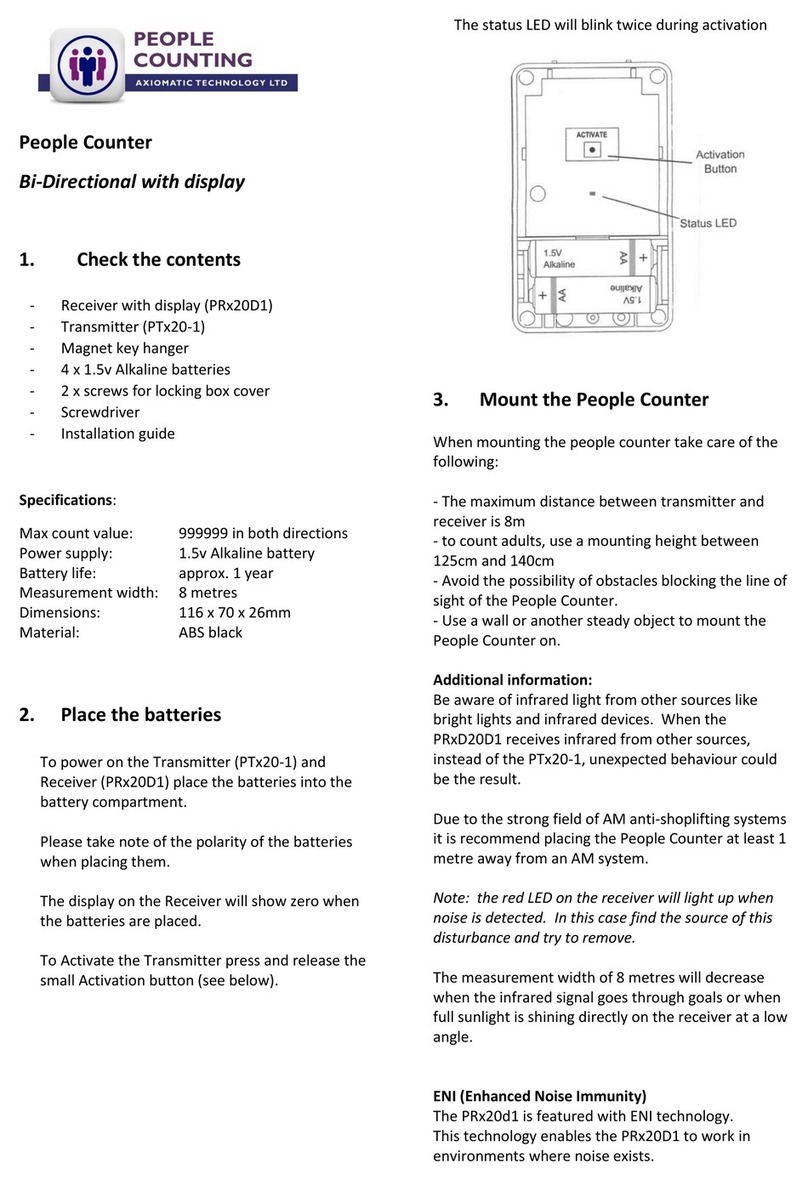

2. INSTALLATION INSTRUCTIONS……………………………………………………..…………................ 12

2.1. Dimensions and Pinout………………………………………………………………..……………… 12

2.2. Installation Instructions ……………………………………………………………...……...….…….. 14

3. CANOPEN ® OBJECT DICTIONARY………………....………………………………..………………….. 16

3.1. NODE ID and BAUDRATE……………….………………………………..……………………….… 16

3.1.1. LSS Protocol to Update………………..……………………………………….………………... 16

3.2. COMMUNICATION OBJECTS (DS-301 and DS-401)…….………………………………..…..… 20

3.2.1. Object 1000h: Device Type…….……………………………....………………………..…........ 21

3.2.2. Object 1001h: Error Register………………..………………….………………………..…........ 22

3.2.3. Object 1003h: Pre-Defined Error Field………..………………………..…..…………….......... 22

3.2.4. Object 100Ch and 100Dh: Guard Time and Lifetime Factor…….…………………………… 23

3.2.5. Object 1010h: Store Parameters…………………………..……………..……………..…........ 24

3.2.6. Object 1011h: Restore Parameters……………………..………………………..…………...... 25

3.2.7. Object 1016h: Consumer Heartbeat Time………..………………………..…......................... 27

3.2.8. Object 1017h: Producer Heartbeat Time………..……………………………………....…....... 28

3.2.9. Object 1018h: Identity Object……………………………..……………………………..…........ 28

3.2.10. Object 1020h: Verify Configuration………………..………………………..…......................... 29

3.2.11. Object 1029h: Error Behaviour……………………………..………………………..………...... 30

3.2.12. RPDO Behaviour.…………………………...……………………………..……………………… 31

3.2.13. TPDO Behaviour……………...……………………………..………………………..………...... 34

3.3. APPLICATION OBJECTS (DS-401)……..………………………………..….…………………….. 36

3.3.1. Object 6000h: DI Read Input 8-bit……….……...………………………………..…………….. 36

3.3.2. Object 6002h: DI Polarity 8-bit……….……..………………………………..………………….. 37

3.3.3. Object 6003h: DI Filter Input 8-bit……….……..………………………………..…………….... 37

3.3.4. Object 6005h: DI Global Interrupt Enable 8-bit……….……..………………………………… 38

3.3.5. Object 6006h: DI Interrupt Mask Any Change 8-bit……….……..……………………………. 39

3.3.6. Object 6007h: DI Interrupt Mask Low-to-High 8-bit……….……..……………………………. 40

3.3.7. Object 6008h: DI Interrupt Mask High-to-Low 8-bit……….……..……………………………. 41

3.3.8. Object 6200h: DO Write Output 8-bit.……..………………………………..…………………... 42

3.3.9. Object 6202h: DO Polarity 8-bit……….……..……………………………………………….…. 42

3.3.10. Object 6206h: DO Error Mode 8-bit……….……..………………………………………..……. 43

3.3.11. Object 6207h: DO Error Value 8-bit……….……..……………………………………………... 44