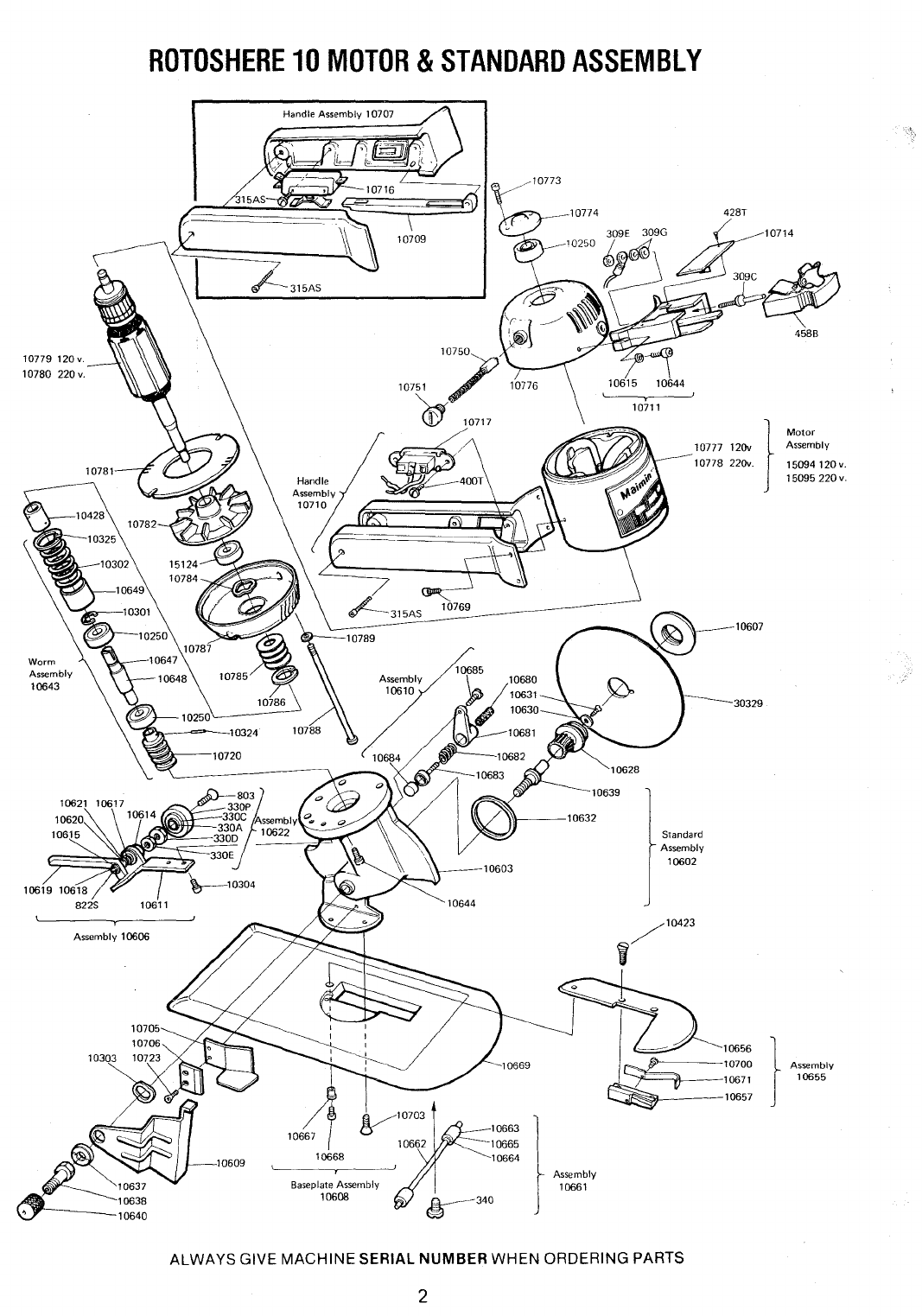

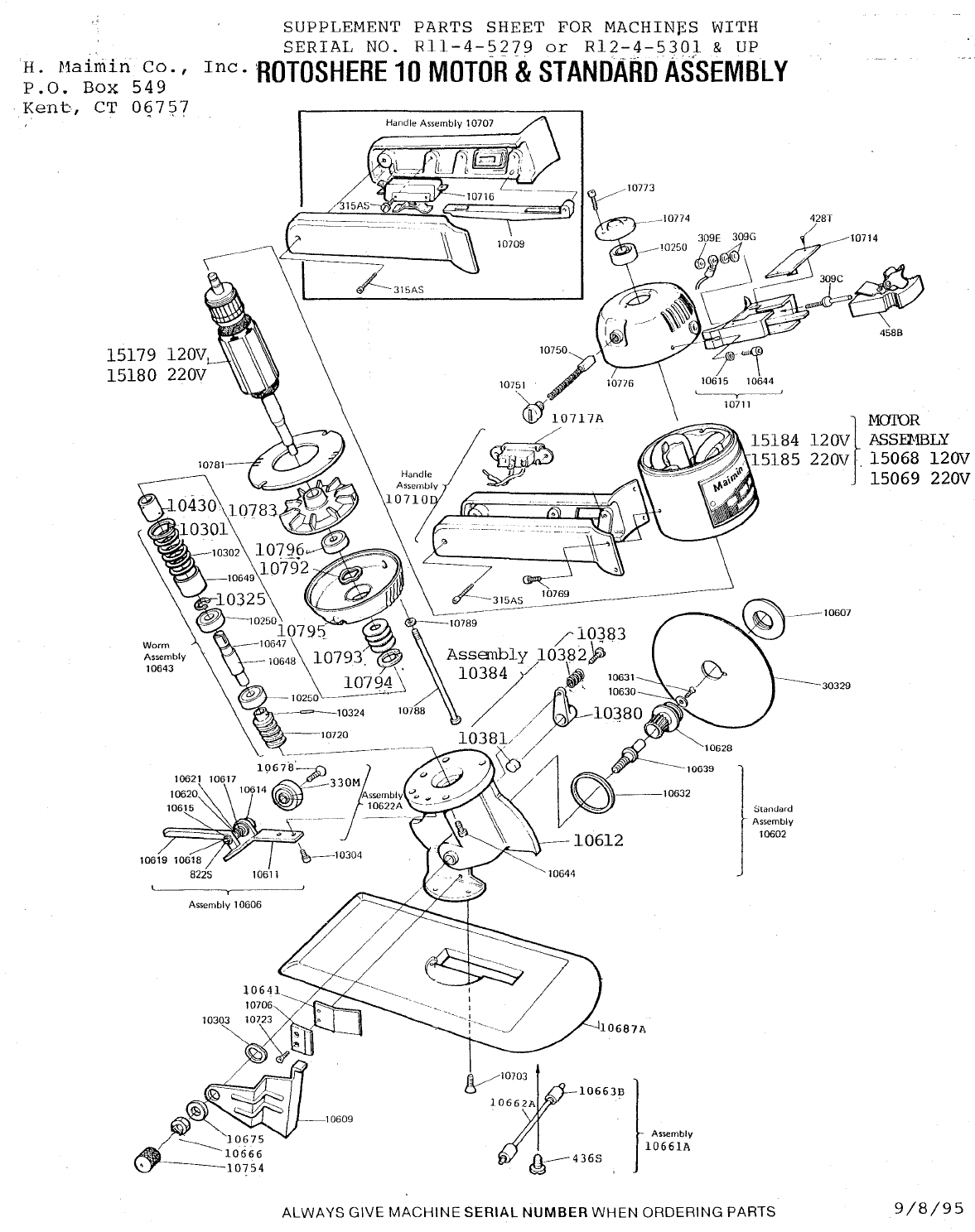

4.

TO

LUBRICATE PAD

10684

Use

light weight oil (#10 weight) to saturate Pad 10684

in Blade Wiper Assembly 10610. Hole for oiling

is

in Wiper

Housing 10681.

5. TO LUBRICATE

GEAR

AND

WORM

ASSEMBLIES

Grease the Gear Assembly 10628 and

Worm

Assembly

10643 monthly

by

turning Cap 10640 one full turn. When

the Cap

is

empty, refill it with Maimin Grease 22028 or

Lubriplate 930-AA.

6. MAINTENANCE SCHEDULE

a) Daily: -Oil Pad I0684

b)

Monthly:-

Grease Gear and Worm Assemblies

Clean motor with compressed air

c) Semi-annually:

-Check

Carbon Brushes 10750

Blow out Roller Shells 10663 with

compressed air (do not oil Roller

Pins 10665)

7.

TO

CHANGE BLADE

30329

Detach Connector 458B, and

io~er

Knife Guard 10609.

Lay the machine on its side. Pull up Blade Wiper Assembly

10610, and rotate it above the Blade. Insert Knife Key

327K into Knife Lock 10607 and turn counter-clockwise

to loosen. Remove Knife Lock. While pulling Throat

Plate Assembly 10655 towards you, pull Blade upwards

and out. Slip new Blade into place, seating it

on

pin

of

gear. Replace Knife Lock, and tighten with Knife Key.

4

8.

TO

CHANGE STONE ASSEMBLY

10622

Depress Sharpener Trigger 10619

to

expose the thin shoul-

der next to Nut 330E. Hold this shoulder with pliers, and

insert 5/32" Hex Key 22064 into Screw 803. Turn Hex

Key to unscrew and remove Stone Assembly. Replace with

new Stone Assembly, and tighten.

9.

TO

CHANGE CARBON BRUSH

10750

Unscrew Brush Cap 10751. Pull out Carbon Brush, and

replace with new one.

10.

TO

REMOVE WORM ASSEMBLY 10643

Take

off

Blade 30329. Remove motor by unscrewing the

four screws 10644, and then take

off

Sharpener Assembly

10606 by unscrewing the two screws 10304. Take out

Coupling 10428 and then the Retaining Ring 10325 from

the top

of

the Standard 10603. Remove Washers 10302.

Pull out

Worm

Assembly 10643.

11.

TO

REMOVE

GEAR

ASSEMBLY

10628

First take out Worm Assembly

as

described in para. 10.

Remove Gear Screw 10631 and Washer 10630. Pull out

Gear Assembly 10628. Do

not

try

to remove Gear Assem-

bly

without

removing Worm Assembly first!

CAUTION:

DO

NOT REMOVE GEAR

SHAFT 10639 FROM STANDARD

10603

AS

SHAFT

IS

POSITIONED

AT

THE FACTORY WITH

SHIMS

FOR CORRECT ALIGNMENT OF THE

GEAR AND

WORM.

H.

MAIMIN

CO.,

INC.

575

EIGHTH AVENUE,

NEW

YORK, N.Y.

10018

U.S.A.

Printed

in

U.S.A.

R105783

From the library of: Superior Sewing Machine & Supply LLC