Contents

Contents ............................................................................... Chapter - Page

1Safety ........................................................................................................................ 1 -1

1.01 Directives ...................................................................................................................1- 1

1.02 General notes on safety ............................................................................................. 1 - 1

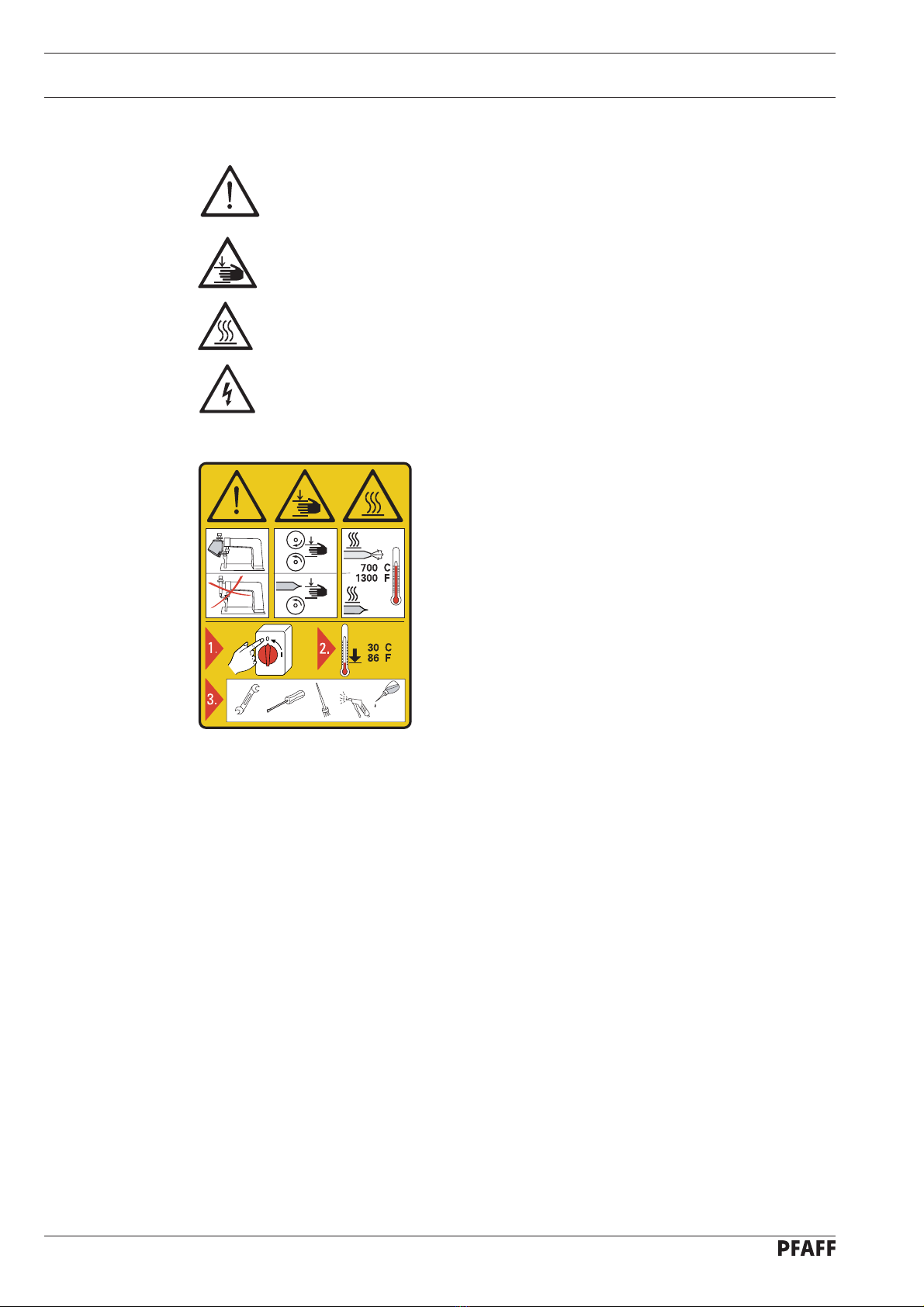

1.03 Safety symbols .......................................................................................................... 1 - 2

1.04 Important notes for the user ...................................................................................... 1 - 2

1.05 Operating and technical staff ..................................................................................... 1 - 3

1.05.01 Operating staff ...........................................................................................................1- 3

1.05.02 Technical staff ............................................................................................................ 1 - 3

1.06 Danger warnings ........................................................................................................ 1 - 4

2Proper use................................................................................................................. 2 - 1

3Specifications ........................................................................................................... 3 - 1

4Machine disposal ..................................................................................................... 4 - 1

5Transportation, packing and storage ...................................................................... 5 - 1

5.01 Transportation to customer’s premises ..................................................................... 5 - 1

5.02 Transportation inside customer’s premises ............................................................... 5 - 1

5.03 Disposal of packing materials ..................................................................................... 5 - 1

5.04 Storage ......................................................................................................................5 - 1

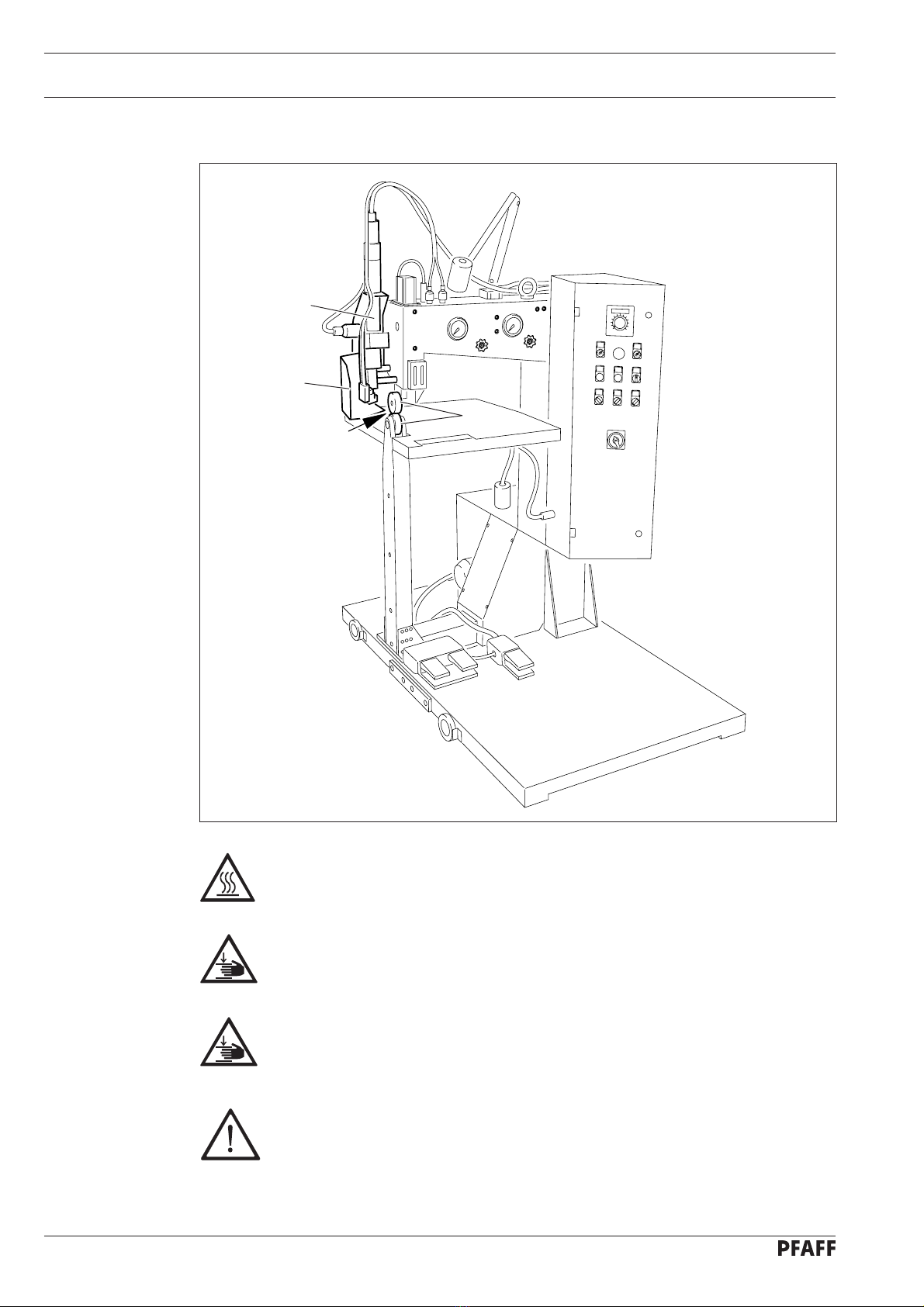

6Explanation of symbols ........................................................................................... 6 - 1

7Controls .................................................................................................................... 7 - 1

7.01 On-off switch ............................................................................................................. 7 - 1

7.02 Air valve ..................................................................................................................... 7 - 1

7.03 Foot switch for raising / lowering the feed rollers ...................................................... 7 - 2

7.04 Foot switch for starting the feed rollers ..................................................................... 7 - 2

7.05 Foot switch for engaging and disengaging the heating element ................................ 7 - 3

7.06 Knee switch / foot switch for mobile drive (only for the PFAFF 8309-026) ................. 7 - 3

7.07 Temperature regulator ............................................................................................... 7 - 4

7.08 Status display of temperature control ........................................................................ 7 - 4

7.09 Regulator for the heat-sealing speeds ........................................................................ 7 - 5

7.10 Reset switch / horn .................................................................................................... 7 - 5

7.11 Switch for heating capacity (only for machines with hot wedge) ............................... 7 - 6

7.12 Switch for the operating direction .............................................................................. 7 - 6

7.13 Switch for the mobile machine drive ( only for PFAFF 8309-026 ) .............................. 7 - 7

7.14 Switch for the automatic operation of the heating element ....................................... 7 - 7

7.15 Adjusting screw for limiting the penetration depth .................................................... 7 - 8

7.16 Regulator for the feed roller pressure and the hot air pressure .................................. 7 - 8

8Installation and commissioning .............................................................................. 8 - 1

8.01 Installation .................................................................................................................. 8 - 1

8.02 Commissioning .......................................................................................................... 8 - 2

8.03 Switching the machine on / off .................................................................................. 8 - 2

8.03.01 Switching machine with hot wedge on / off ............................................................... 8 - 2

8.03.02 Switching machine with hot-air nozzle on / off ........................................................... 8 - 3