Makermade MASLOW CNC User instructions

SETTING UP YOUR MASLOW CNC

FROM THE MAKERMADE LEARNING LIBRARY

TABLE OF CONTENTS

1.0 What’s in Your Kit?

1.1 Building the Frame

1.2 Adding the Electronics

1.3 Building the Temporary Sled

1.4 Installing the Z-Axis

1.5 Calibrating Your Maslow

1.6 Building Final Sled

1.0 WHAT’S IN YOUR KIT?

FROM THE MAKERMADE LEARNING LIBRARY

THIS WORK IS LICENSED UNDER THE CREATIVE COMMONS ATTRIBUTION-SHAREALIKE 4.0 INTERNATIONAL LICENSE.

AC POWER CABLE

X/Y Motor Mounts(2)

RING BRACKET

X/Y MOTORS

ARDUINO MOTOR &SHIELD DC POWER SUPPLY

USB CABLE USB FLASH DRIVE

Z AXIS MOTOR CABLE

CHAINS(2)

RING BRACKET MOUNTS(3)RING BEARINGS(4) RING CARRIAGE(2)

X/Y MOTOR CABLES

Z AXIS MOTOR MOUNTS(2)Z AXIS MOTOR

1

5

9

13

2

6

10

14

3

7

11

15

4

8

12

16

WHAT’S IN YOUR KIT? PG. 2LAST UPDATE 05.31.19

HARDWARE BAGS

Attaches chains to frame

Multiple uses

Attaches carriages to ring

Cords, hardware for attaching

to frame

Fastens motor to mounts

Fastens L-brackets to ring,

and to sled

Holds bricks in place on sled

Attaches Arduino to frame

Attaches Z axis to router

and sled

BAG #1

BAG #4

BAG #7

BAG #2

BAG #5

BAG #8

BAG #3

BAG #6

BAG Z

1.1 BUILDING THE FRAME

TOOLS NEEDED:

Saw

Power Drill

Screwdrivers

Safety goggles

BUILD TIME:

About 5 hours, plus

glue drying time

COST:

Approximately $90

CUT LIST:

2x4s

(1)120”

(1) 88”

(2) 82”

(2) 79”

(2) 60”

(2) 34”

(2) 30”

(2) 28”

(2) 7”

(4)3.5”

MATERIALS LIST:

(7) 10’ long 2x4s

(1) 8’ long 2x4

(1) 6’ long 2x4

(1) 4X8 sheet .75” plywood

(75-100) 2.25” wood screws

Wood glue

Hardware & parts from kit

Note: Lumber dimensions are not critical, if 2x4s are not available in your area the local

equivalent will work. When cutting, try to keep the ends as square as possible, but small

errors in the lengths of any of the parts will not affect accuracy of the machine.

DESIGN BY THE MASLOW COMMUNITY, PARTICULARLY USERS DLANG AND MADGRIZZLE

Precision Level

Difficulty Level

THIS WORK IS LICENSED UNDER THE CREATIVE COMMONS ATTRIBUTION-SHAREALIKE 4.0 INTERNATIONAL LICENSE.

BEFORE BEGINNING

Acquaint yourself with

standard practices for

workshop safety.

BUILDING THE DEFAULT FRAME PG. 2LAST UPDATE 05.22.19

STEP 1: BUY MATERIALS

2X4 (or equivalent lumber)

6'

10'

10'

10'

10'

10'

10'

8'

PLYWOOD

PRO TIP:

Label the parts as you

cut them, you’ll be glad

you did.

BUILDING THE DEFAULT FRAME PG. 3LAST UPDATE 05.22.19

STEP 2: CUT OUT PIECES AS SHOWN

2X4 (or equivalent lumber)

120” TOP BEAM

88” REAR CROSSMEMBER

34” VERTICAL

34” VERTICAL

30” KICKER

30” KICKER

28” DIAGONAL 28” DIAGONAL

82” FRONT CROSSMEMBER: LOWER

82” FRONT CROSSMEMBER: UPPER

79” FRONT LEG

79” FRONT LEG

60” BACK LEG 60” BACK LEG

3.5” SPACER

3.5” SPACER

3.5” SPACER

3.5” SPACER

7” BEAM

7” BEAM

PLYWOOD

BUILDING THE DEFAULT FRAME PG. 4LAST UPDATE 05.22.19

FRONT LEG 79”

KICKER 30”

Spacer & back

leg both go

beneath kicker

11.5” 1.75”

FRONT LEG 79”

KICKER 30”

90º

KICKER

FRONT LEG

KICKER

FRONT LEG

BACK LEG

KICKER

SPACER

FRONT LEG

BACK LEG 60”

KICKER

FRONT LEG

BACK LEG 60”

SPACER

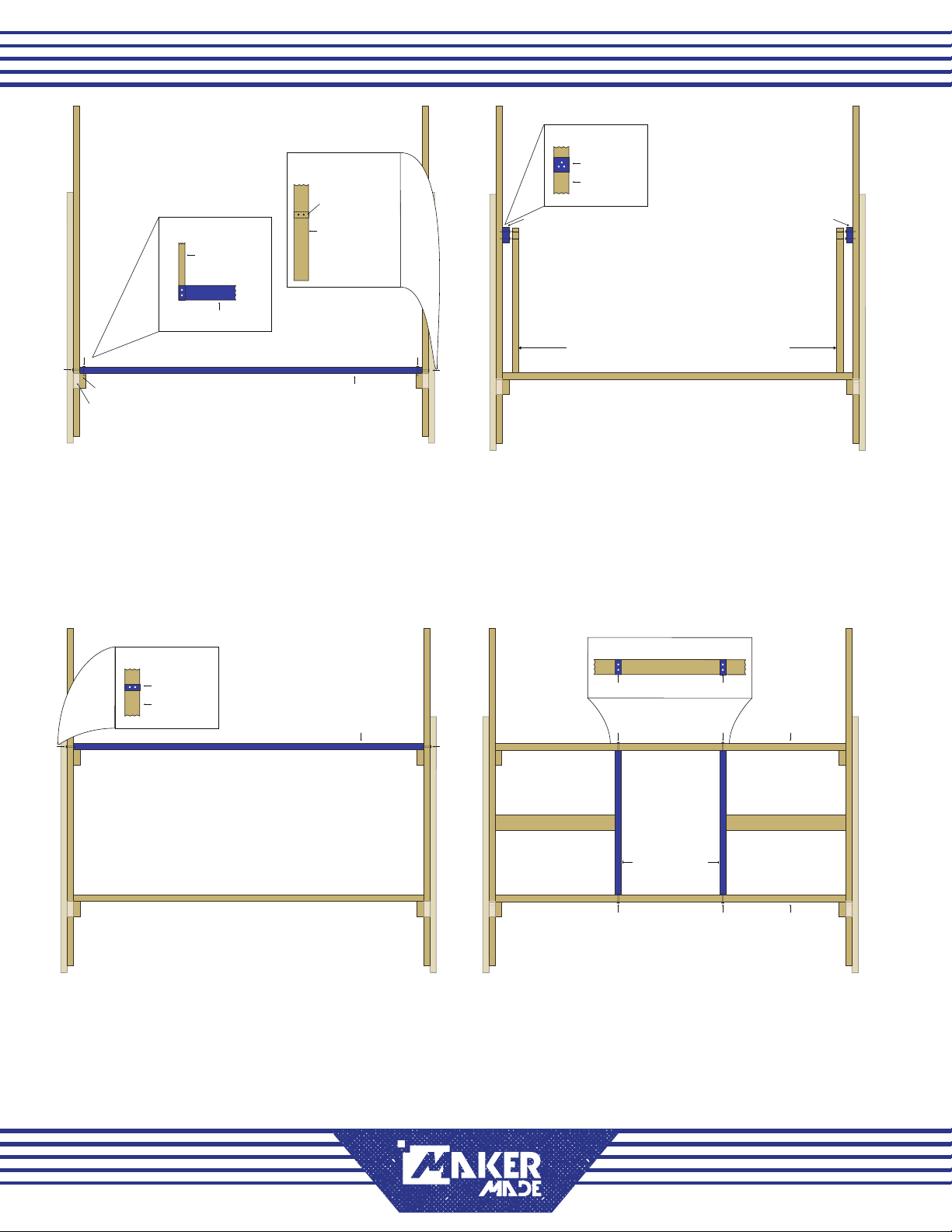

STEP 3/4A ATTACH KICKERS TO FRONT LEGS

•Kickers at 90° angle to front legs

•Kickers 11.5” from bottom of front legs, and

overhanging by 1.75”

•Screw through top of kickers into front legs

•Screw through top of kickers into spacers

•Flip each assembly over for next step

STEP 3/4C POSITION BACK LEGS

•Rotate back legs out to end of kickers

•Screw bottom of back legs to kickers

•Add more screws to top of back legs

STEP 3/4B ADD BACK LEGS

•Place back legs on top of front legs,

aligning bottom ends

•Mark center of back legs 1” from top end

•Screw through top center of back legs

into front legs at marked spot

•Only 1 screw per leg, NO GLUE

Next steps are most easily done

with front legs horizontal to floor,

as shown. Prop with scraps to keep

things level.

LEGS ARE NOW COMPLETE!

BUILDING THE DEFAULT FRAME PG. 5LAST UPDATE 05.22.19

FRONT LEG

KICKER

FRONT LEG

BACK LEG

KICKER

FIGURE 1

FIGURE 2

FRONT CROSSMEMBER

SPACER

FRONT

CROSSMEMBER

FRONT

CROSSMEMBER

LOWER 82”

FRONT LEG

SPACER

FIGURE 4

FRONT LEG

FRONT

CROSSMEMBER

UPPER 82”

VERTICALS 34”

Just use to measure, DO NOT ATTACH!

SPACER

FRONT LEG

SPACER

SPACER

FIGURE 3

FRONT LEG

VERTICALS 34”

FRONT

CROSSMEMBER

UPPER

FRONT

CROSSMEMBER

LOWER

DIAGONAL 28”DIAGONAL 28”

VERTICAL

FIGURE 5

VERTICAL

CROSSMEMBER

STEP 5A ATTACH LOWER FRONT CROSSMEMBER

•Rest lower front crossmember on kickers

•Screw from top of crossmember into each

kicker- see Figure 1

•Screw from side of each front leg into

crossmember- see Figure 2

STEP 5C ATTACH UPPER FRONT CROSSMEMBER

•Rest upper front crossmember on spacers

•Screw through sides of front legs into

crossmember

STEP 5B ADD SPACERS

•Use verticals to measure placement of

spacers on inside of front legs

•DO NOT ATTACH VERTICALS IN THIS STEP

•Screw through spacers into front legs

STEP 6 ATTACH VERTICALS

•Use diagonals to place verticals

•DO NOT ATTACH DIAGONALS IN THIS STEP

•Screw through top crossmember into verticals

•Screw through bottom crossmember into

verticals

View from above, front

legs horizontal to oor,

back legs sticking up

BUILDING THE DEFAULT FRAME PG. 6LAST UPDATE 05.22.19

DIAGONAL 28”

DIAGONAL 28”

FRONT

CROSSMEMBER

UPPER

FRONT

CROSSMEMBER

LOWER

FRONT LEG

approx

17”

approx

18”

REAR CROSSMEMBER 88”

KICKER

SPACER

FRONT LEG

BACK LEG

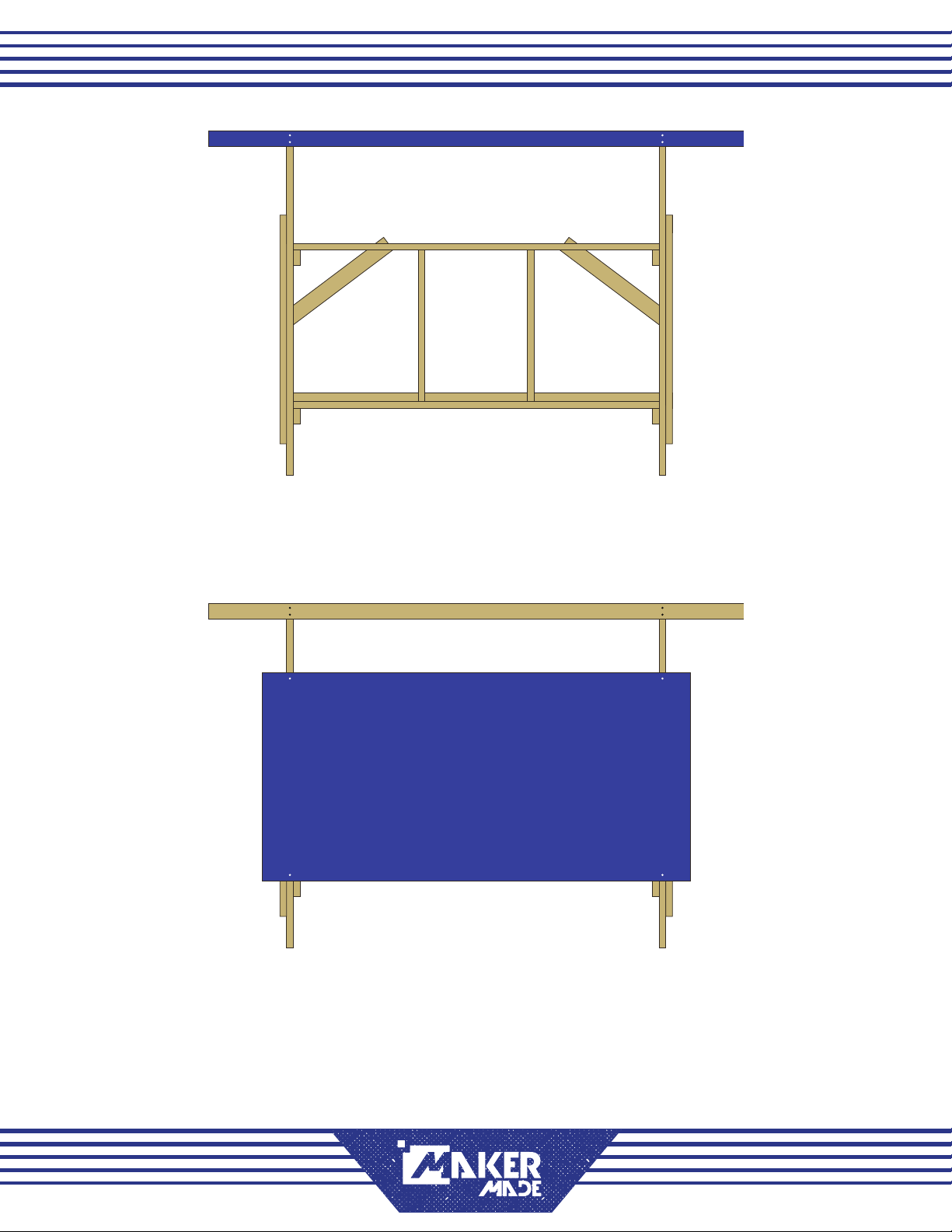

STEP 7 ATTACH DIAGONAL BRACING

•Rest diagonals with one end on front leg,

one leg on upper crossmember

•Screw diagonals in place on each end

•Placement of diagonals need not be exact

STEP 9 ATTACH SIDE BEAMS

•Beams were placed on cut list to have

one factory end, this end should face out

so top beam has a flat surface to rest on

•Place beams at 90° angles to each front leg

•Screw through beams into front legs

STEP 8 ATTACH REAR CROSSMEMBER

•Rest rear crossmember on top of kickers

where they protrude from back legs

•Screw through rear crossmember into

back legs

ALMOST FINISHED!

BUILDING THE DEFAULT FRAME PG. 7LAST UPDATE 05.22.19

TOP BEAM 120”

TOP BEAM

4’x8’ PLYWOOD SHEET

STEP 10 ATTACH TOP BEAM

•Center top beam across front

•Screw through top beam into 7” beams

on each side

STEP 11 STAND UP FRAME & ATTACH PLYWOOD

•Rest plywood on kickers

•Attach with screws through front of

plywood into each front leg

You now have a complete frame!

NEXT STEP: ATTACHING THE ELECTRONICS

THIS WORK IS LICENSED UNDER THE CREATIVE COMMONS ATTRIBUTION-SHAREALIKE 4.0 INTERNATIONAL LICENSE.

TOOLS NEEDED:

Power Drill

Screwdrivers

Safety goggles

Computer or tablet

Internet connection

BUILD TIME:

About 1 hour

MATERIALS LIST:

Part #1 AC Power Cable

Part #2 Arduino with Heat Shield

Part #4 DC Power Supply

Part #9 USB Cable

Part #10 Flash Drive (optional)

Part #11 X and Y Motor Cables

Part #12 X and Y Motor Mounts

Part #13 X and Y Motors

Hardware Bag #5

Hardware Bag #6

Before adding the electronics to the frame, there’s a bit of setup- downloading and

adding programs and information, that needs to be done

1.2: ADDING THE ELECTRONICS

DESIGN BY THE MASLOW COMMUNITY, PARTICULARLY USERS DLANG AND MADGRIZZLE

Precision Level

Difficulty Level

STEP 1: CONNECT THE MOTORS

PART #2 Arduino with Heat Shield

PART #11 X & Y Motor Cables

PART #13 X & Y Motors

•X and Y motor cables, as well as motors,

are interchangeable at this point

•Insert one end of a cable into each motor

•Insert other ends into to Ports 1 and 3 on

Arduino with yellow wire at bottom as shown

•Port 3 controls left motor Port 1 controls

right motor as viewed when facing the

Maslow CNC.

STEP 2: CONNECT THE POWER SUPPLY

PART #1 AC Power Cable

PART #3 DC Power Supply

•Plug DC power supply into shield

•Arduino also has a power supply port,

plugging power supply into it will not

damage it, but will not provide power to

motors

•Connect power cable to DC Power Supply

•Plug power cable into surge protected

electrical outlet

STEP 3: CONNECT THE USB CABLE

PART #9 USB Cable

Computer or tablet

•Plug USB cord into Arduino

•Plug other end into your computer

•USB light will come on to indicate that

board is connected and receiving power

from your computer

X

X

ATTACHING THE ELECTRONICS PG. 2LAST UPDATE 06.01.19

STEP 4: DOWNLOAD THE ARDUINO IDE

Internet connection

Computer or tablet

•In your browser, navigate to

https://www.arduino.cc/en/Main/Software

•Download latest version of Arduino IDE

•Note: Some users have reported problems

with “Windows App” version

•Open zip folder

•Install program on your computer

•Open program

STEP 6: SET UP FIRMWARE

•Click File -> Open

•Select cncctrlv1.ino

•Click Tools -> Board

•Select Arduino/Genuino Mega or Mega 2560

•Click Tools -> Port -> Your Port

•Select port- on Windows, COM3, on Mac

and Linux computers dev/tty/

•If unsure, disconnect USB cable from

Arduino, check which option disappears.

STEP 5: DOWNLOAD MASLOW FIRMWARE

•In your browser, navigate to

http://github.com/MaslowCNC/Firmware/releases/

•Download latest version of rmware

•Open zip folder

•Install program on your computer

STEP 7: ADD FIRMWARE TO ARDUINO

•Click upload button in top left corner

•This uploads rmware to Arduino

•Linux users: if getting timeout or

permissions errors, try adding username to

dialout group then logging out and back in

•When upload nishes, close Arduino IDE

STEP 8: INSTALL GROUND CONTROL

•In your browser, navigate to

https://github.com/MaslowCNC/

GroundControl/releases

•Download latest version of Ground Control

WINDOWS USERS

•Open zip folder

•Click Launch Ground Control” shortcut

MAC USERS

•Install Ground Control by moving it into

your applications folder

•Click icon in applications folder

•Select “Open”

Linux and Raspberry Pi users:

•Reference instructions online at http://

maslowcommunitygarden.org/

GroundControl.html?instructions=true

STEP 9: CONNECT GROUND CONTROL TO

MASLOW

•In Ground Control, click ACTIONS on top left

•Click PORTS, a list of ports will appear

•Select same port you used in Step 6

•Click CONNECT

THAT PART’S DONE! YOU’RE NOW READY TO

INSTALL THE ELECTRONICS ON THE FRAME.

BEFORE PROCEEDING DISCONNECT POWER

CABLES, USB CABLES, AND MOTOR CABLES.

NOTE: Ground Control is the program

which runs on your computer and lets

you control your Maslow CNC.It’s free

and is updated often.

ATTACHING THE ELECTRONICS PG. 3LAST UPDATE 06.01.19

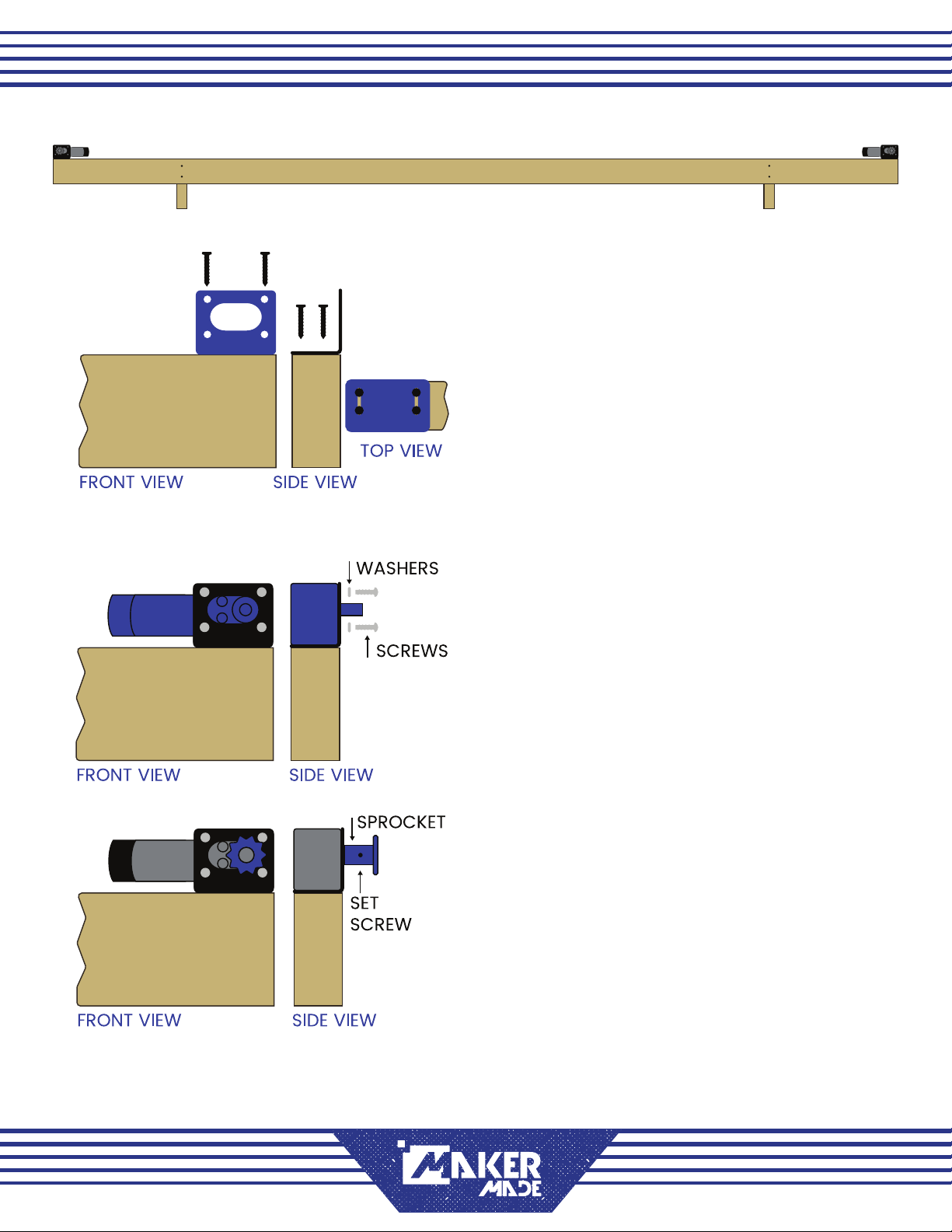

FRONT VIEW SIDE VIEW

STEPS 12-14 TAKE PLACE ON THE TOP BEAM OF THE FRAME, REPEATED ON EACH END

FRONT VIEW

STEP 12: INSTALL MOTOR MOUNTS ON FRAME

BAG #4 (8) wood screws

PART #12 X/Y Motor Mounts

•Position motor mounts on beam ush with

front and side edges

•Using two screws per slot on base of each

motor mount, fasten motor mounts to

beam with wood screws

STEP 13: ATTACH MOTORS TO MOUNTS

BAG #5 (8) small screws, (8) lock washers

PART#13 X/Y Motors

•Place one motor in each bracket

•Slide lock washers over screws

•Fasten screws through front of motor

mount into aligned holes in motor

STEP 14: INSTALL SPROCKETS ON MOTOR SHAFTS

BAG#1 (2) sprockets, (2) set screws

Allen wrench

•Insert set screw in hole on side of sprocket

•Screw in slightly with allen wrench

•Place sprocket over motor shaft

•Tighten set screw with allen wrench

ATTACHING THE ELECTRONICS PG. 4LAST UPDATE 06.01.19

STEP 16 RECONNECT ELECTRONICS

PARTS #1-2 Power Cable, Power Supply

PART #9 USB Cable

PART #11 X/Y Motor Cables

•Attach Arduino to motors with cables

•Connect power supply to Arduino

•Connect USB cord to Arduino

•For more details review electronics

setup guide

USB CABLE

POWER CABLE

BACK OF FRAME

ARDUINO MOTOR & SHIELD

STEP 15 ATTACH THE ARDUINO

BAG #6 screws, standoffs

PART #2 Arduino

•Gently remove shield from Arduino

•Position Arduino in center of plywood

•Insert screws through holes

•Slide standoffs over screws

•Screw into plywood

•Re-attach shield

STEPS 15-16 TAKE PLACE ON THE BACK OF THE FRAME

ATTACHING THE ELECTRONICS PG. 5LAST UPDATE 06.01.19

NEXT STEP: BUILDING THE TEMPORARY SLED

1.3 BUILDING THE TEMPORARY SLED

TOOLS NEEDED:

Router, .25” router bit

Handsaw or Circular Saw

Phillip’s Head Screwdriver

Power Drill, .25” & .5” drill bits

Socket Wrench, various sizes

5/16 Allen Wrench

Pencil

Safety goggles

Clamps (optional)

CUT LIST:

(1) 18x18” square

(2) 1x5.5” rectangles**

MATERIALS LIST:

(1) 4x8 Plywood, .75” thick*

(2) Bricks**

(3) Size 10-32 Machine Screws

Part #5 Ring Bearings

Part #6 Ring Mount

Part #7 Ring Bracket Mounts

Part #8 Ring Carriage

Hardware Bags #3,6,7,8

*If you have scrap plywood on hand, it’s not neccesary to buy a whole sheet of plywood

**If using MakerMade metal brickholders bricks should be no more than 4.5” wide

DESIGN BY THE MASLOW COMMUNITY, PARTICULARLY USERS DLANG AND MADGRIZZLE

THIS WORK IS LICENSED UNDER THE CREATIVE COMMONS ATTRIBUTION-NONCOMMERCIAL-NODERIVATIVES 4.0 INTERNATIONAL LICENSE.

Precision Level

Difficulty Level

SLED BASE

BRICK

HOLDERS

1X5.5”

18”

18”

TEMPORARY SLED ASSEMBLY PG. 2LAST UPDATE 06.11.19

STEP 1 CUT OUT PLYWOOD PARTS

Saw, ruler

•Mark dimensions of parts on plywood

•Exactness is not critical for temporary sled

•Using hand or circular saw, cut out parts

STEP 3 REMOVE ROUTER HANDLES, BASEPLATE

5/16 allen wrench, screwdriver

•Remove cap on side of handle

•Bolt inside hole may be unscrewed with a

5/16 allen wrench

•Turn router over so baseplate is up

•Use Phillips-head screwdriver to remove 3

machine screws from bottom of baseplate

•Set router and baseplate aside

SLED BASE

BRICK

HOLDERS

1X5.5”

18”

18”

1.5” DIAMETER

NOTE: These steps are for the Rigid

router, other routers may differ

CAP BOLT

BEHIND CAP

STEP 2 CUT CENTER HOLE FOR BIT

Router, .25” router bit, pencil

•Mark 1.5”x1.5” hole in center of sled

•Use router to cut out hole, going down

approx 1/10” per pass

TOP VIEW SIDE VIEW

L-Brackets

Ring Bracket

STEP 4 ATTACH L-BRACKETS TO RING

BAG #8 (6)nuts, (6)bolts, allen wrench

PARTS #6-7 Ring bracket, (3)L-brackets

•Line up L-brackets as shown with

rectangular brackets on ring

•Insert bolts from inside of ring bracket out

through L-brackets, two per bracket

•Secure with nuts, using allen wrench to

tighten

TEMPORARY SLED ASSEMBLY PG. 3LAST UPDATE 06.11.19

Shoulder

bolt

Ring

bearing

Washer

Washer

Nut

TOP VIEW SIDE VIEW

STEP 6 MARK PLACEMENT OF COMPONENTS

Pencil

•Place components on sled as shown above

•Baseplate of router in center of sled

•Ring assembly centered around baseplate

•Bricks and holders in corners, exact

placement not critical

•Use pencil to mark 3 holes in baseplate

•Mark placement of ring and brick holders

•Mark .5” circle as shown, middle of sled,

halfway between top edge and ring

•If using Z-axis with temporary sled, leave

room for that as marked above

STEP 5 ATTACH CARRIAGES TO RING

BAG #7 (4) shoulder bolts, (4) nuts,

(8) washers, allen wrench

PART #2 Ring Bearings

PART #5 Carriage mounts

•Place one carriage on either side of ring

•Insert shoulder bolt up through bottom of

carriage, slip one washer over bolt, then

one ring bearing, then another washer

•Push shoulder bolt through top of

carriage, fasten with nut

•Do this twice for each carriage

•Use allen wrench to tighten bolts

•Bearings should still rotate freely

STEP 7 DRILL HOLES

Power drill, .25” and .5” drill bit, optional

clamps

•Place brick holders in marked spots, clamp

into place (optional but helpful)

•Mark a spot on each end of holder just

outside of where the brick will be

•Drill through holders and sled with .25” bit

•Drill 3 holes where marked for router with

.25” bit

•Drill top hole with .5” bit

TEMPORARY SLED ASSEMBLY PG. 4LAST UPDATE 06.11.19

STEP 9 ATTACH BRICKS TO SLED

Bag #3 Nuts, bolts

(2) brick holders

•Insert bolts through pre-drilled holes from

bottom of sled through to the top

•Place bricks between bolts

•Place wooden brick retainers over bolts

•Secure with nuts

STEP 10 ATTACH RING TO SLED

BAG #8 (18) small screws

•Place ring on sled centered around router

•Each L-bracket has six small holes, insert a

small screw through each hole

•Fasten with Phillips-head screwdriver

STEP 8 ATTACH ROUTER, TO SLED

(3) 10-32 machine screws

•Insert screws through pre-drilled holes

from bottom of sled into router

•Tighten with Phillips-head screwdriver

TOP VIEW SIDE VIEW

TOP VIEW SIDE VIEW

TOP VIEW SIDE VIEW

NEXT STEP: INSTALLING THE Z-AXIS

TEMPORARY SLED ASSEMBLY PG. 5LAST UPDATE 06.11.19

TERMS OF USE

This work is licensed under the

CREATIVE COMMONS

Attribution-NonCommercial-NoDerivatives

4.0 International License

To view a copy of this license

visit http://creativecommons.org/licenses/by-nc-nd/4.0/

or send a letter to

Creative Commons

PO Box 1866

Mountain View, CA 94042

YOU ARE FREE TO:

Share — copy and redistribute the material in any medium or format

The licensor cannot revoke these freedoms as long as you follow the license terms.

UNDER THE FOLLOWING TERMS:

Attribution — You must give appropriate credit, provide a link to the license, and

indicate if changes were made. You may do so in any reasonable manner, but not in

any way that suggests the licensor endorses you or your use.

NonCommercial — You may not use the material for commercial purposes.

NoDerivatives — If you remix, transform, or build upon the material, you may not

distribute the modified material.

No additional restrictions — You may not apply legal terms or technological measures

that legally restrict others from doing anything the license permits.

NOTICES:

You do not have to comply with the license for elements of the material in the public

domain or where your use is permitted by an applicable exception or limitation.

No warranties are given. The license may not give you all of the permissions necessary

for your intended use. For example, other rights such as publicity, privacy, or moral

rights may limit how you use the material.

Table of contents