Makino V55 Operating manual

Table of contents

Other Makino Sander manuals

Popular Sander manuals by other brands

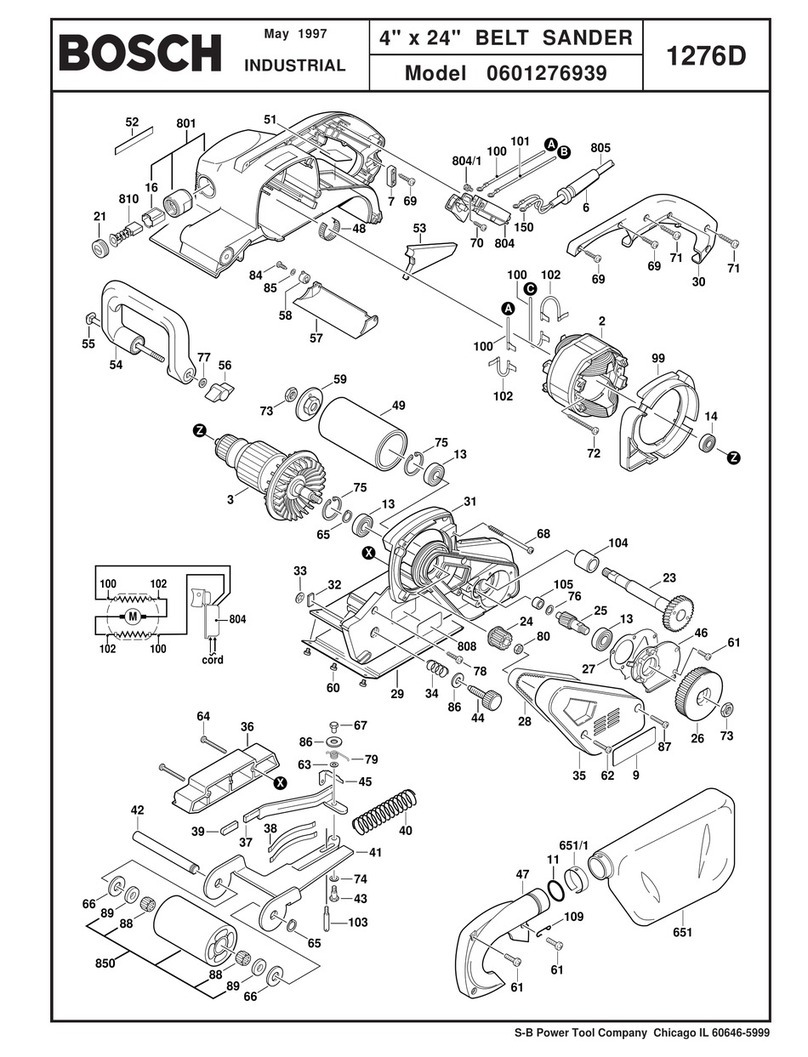

Bosch

Bosch 601276939 parts list

Dynabrade

Dynabrade 52413 Important operating, maintenance and safety instructions

Parkside

Parkside PHS 160 A1 Operation and safety notes

Makita

Makita 9032 instruction manual

Pallmann

Pallmann Spider Translation of the original instruction

Makita

Makita M9202 instruction manual

Makita

Makita 9045B user guide

Pacific

Pacific SEARAY 175 Operating & maintenance instructions

Craftsman

Craftsman 315.268191 Operator's manual

Parkside

Parkside PSDS 240 A1 Original operating instructions

Black & Decker

Black & Decker Mouse MS800 instruction manual

Chicago Pneumatic

Chicago Pneumatic CP3750-085AA Safety information

Jet

Jet 22-44 OSC Operating instructions and parts manual

RIDGID

RIDGID R2600 Operator's manual

EINHELL

EINHELL TP-BS 18/457 Li BL Original operating instructions

Ryobi

Ryobi P430 Operator's manual

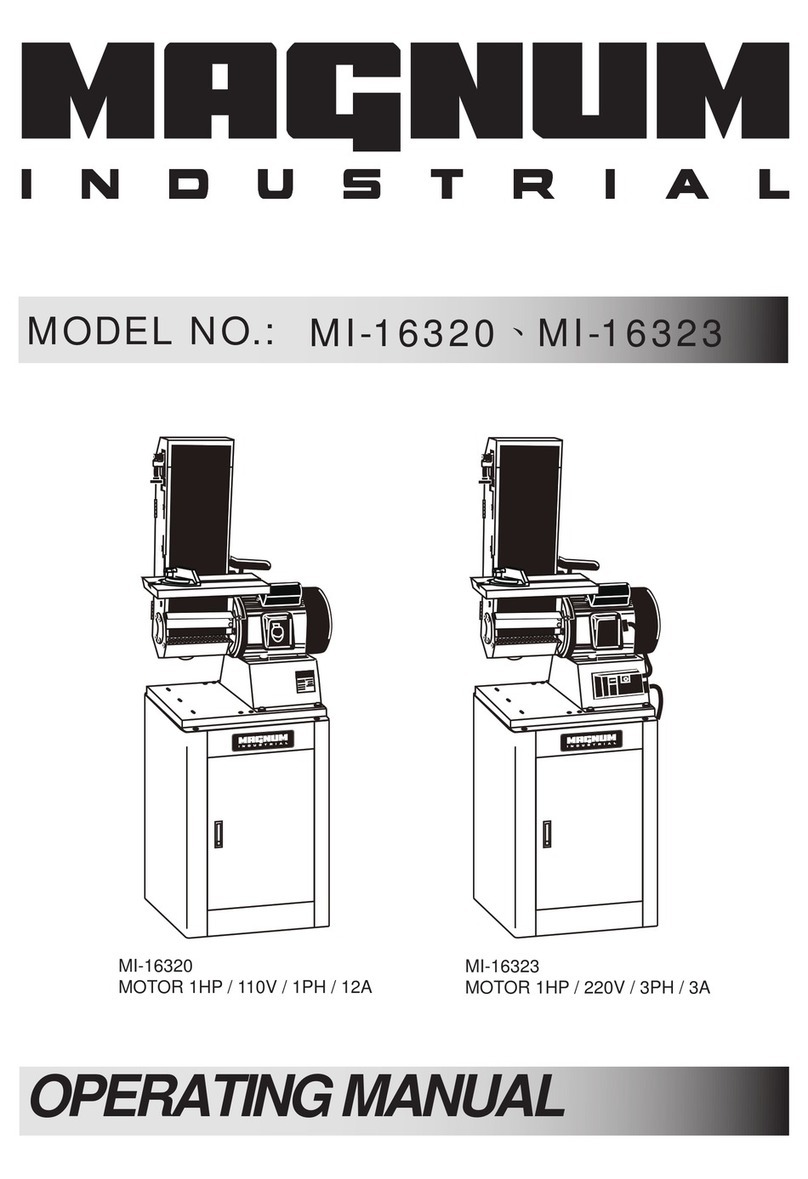

Magnum Industrial

Magnum Industrial MI-16320 operating manual

Meister

Meister MFS320-1 Translation of the original instructions